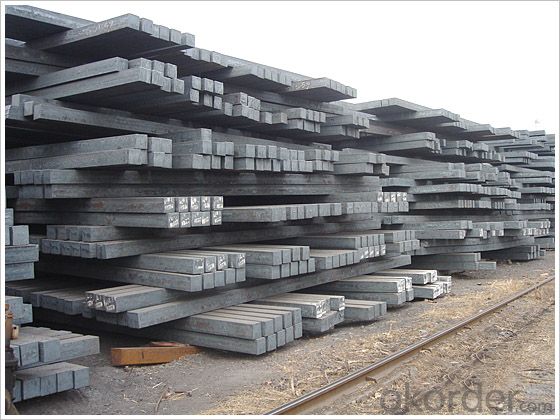

High quality steel billet product Q195 Q35

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1) Suitable for making various strong cutting tool abrasion resistance, impact resistance.

2) Used to produce all kinds of high hard and super hard saw blade, drill, tap, broach, gear hob and various kinds of milling cutter.

3) Used for advanced punching die, screw die, and the toughness and complicated shape of the punch, etc.

4) Is used for cold forging die and drawing mode, etc.

5) Recommended watchcase factory, screw factory and other cold stamping products industry use.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Standard: GB,

-Grade: Q195 or equivalent.

-Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

Measures of HR Square Bar (small measures):

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

7 | 0.385 | 22 | 3.80 |

8 | 0.502 | 24 | 4.52 |

9 | 0.636 | 25 | 4.91 |

10 | 0.785 | 26 | 5.30 |

11 | 0.950 | 28 | 6.15 |

12 | 1.13 | 30 | 7.06 |

13 | 1.33 | 32 | 8.04 |

14 | 1.54 | 34 | 9.07 |

15 | 1.77 | 36 | 10.17 |

16 | 2.01 | 38 | 11.24 |

17 | 2.27 | 40 | 12.56 |

18 | 2.54 | 42 | 13.85 |

19 | 2.82 | 45 | 15.90 |

20 | 3.14 | 48 | 18.09 |

21 | 3.46 | 50 | 19.63 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: (length of a side)2 * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

FAQ:

Q1: Can stainless steel rust?

A1: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q2: How do you package the angle steel when shipping?

A2: All goods are packed in bundles with steel strips and shipped by container or break bulk.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: How are steel billets labeled for identification purposes?

- Steel billets are labeled for identification purposes using a combination of alphanumeric codes and markings. These labels provide crucial information about the steel billet's composition, size, and other important details. The most common method of labeling steel billets involves stamping or engraving the required information directly onto the surface of the billet. This can include details such as the grade of steel, heat number, lot number, and the manufacturer's symbol or logo. These markings are typically made using industrial-grade ink or through a process called electrochemical etching, which ensures durability and legibility even in harsh environments. Additionally, steel billets may also have identification tags or labels attached to them, providing further information that cannot be easily engraved or stamped. These tags or labels may include barcodes, QR codes, or RFID tags, which can be scanned or read using specialized equipment to quickly access the relevant information. By using these labeling methods, steel billets can be easily identified, tracked, and traced throughout their lifecycle, ensuring quality control, inventory management, and efficient production processes in the steel industry.

- Q: How are steel billets used in the production of mining components?

- Steel billets are used in the production of mining components as they serve as the raw material for shaping and forming various mining equipment such as rods, bars, plates, and shafts. These billets are melted and then cast into specific shapes and sizes, which are then machined, welded, or forged to create durable and robust components that can withstand the harsh conditions of mining operations.

- Q: How are steel billets cut and shaped into desired forms?

- Steel billets, also referred to as long, rectangular bars of raw steel, undergo a process known as steel billet shaping to achieve the desired forms. This process consists of multiple steps that facilitate the transformation of the billets into various shapes and sizes, depending on the intended end product. The initial step in shaping steel billets involves cutting them into more manageable lengths. This is typically accomplished through the use of a sawing process, employing high-speed rotating blades. The choice between circular or bandsaw blades is determined by the specific cutting requirements. Once the billets are cut into smaller lengths, they are then subjected to preheating in a furnace, where they are heated to a specific temperature. This preheating process is crucial as it enhances the malleability of the steel, making it easier to shape. The temperature and duration of preheating vary based on the type of steel and the desired final shape. Following preheating, the billets are transferred to a shaping machine, such as a rolling mill or a forging press. These machines exert significant pressure on the heated billets, deforming them into the desired shape. Rolling mills employ a series of rollers to gradually shape the billets into forms like bars, rods, or sheets. Conversely, forging presses apply immense force to reshape the billets by compressing them between dies or molds. Throughout the shaping process, the billets may undergo additional heat treatments, including quenching or tempering, to enhance their mechanical properties. Quenching rapidly cools the shaped billets, increasing their hardness, while tempering involves reheating and slowly cooling them to improve toughness and durability. Finally, after the steel billets have been shaped into the desired forms, they may undergo further processing steps, such as machining, grinding, or surface finishing, to achieve the required dimensional accuracy and surface quality. These additional processes ensure that the steel products meet specific tolerances and surface requirements. In conclusion, steel billets undergo a combination of cutting, heating, shaping, and additional processing steps to achieve the desired forms. This allows the raw steel material to be transformed into various products, serving the diverse needs of different industries, ranging from bars and rods to sheets and other complex shapes.

- Q: How does the quality of steel billets affect the quality of the final product?

- Determining the quality of the final steel product heavily relies on the quality of steel billets. Steel billets are semi-finished products that undergo a continuous casting process to serve as raw materials for downstream steel products. To begin with, the chemical composition of steel billets greatly affects the quality of the end product. Steel is primarily an alloy of iron and carbon, with additional elements like manganese, chromium, nickel, and others. The presence and precise amount of these alloying elements in the billets have a significant impact on the properties of the final steel, including strength, hardness, ductility, and corrosion resistance. Any variation or deviation in the chemical composition of the billets can lead to undesired changes in the characteristics of the final product. Furthermore, the physical properties of steel billets, including their size, shape, and internal structure, directly influence the quality of the final steel product. The dimensions and geometry of the end product are determined by the size and shape of the billets, ensuring proper fit and functionality. Moreover, the absence of defects like cracks, voids, or inclusions in the internal structure of the billets is crucial for producing high-quality steel products. Imperfections in the billets can propagate and cause failures, compromising the strength and overall quality of the final product. Additionally, the quality of the final steel product is influenced by the manufacturing process of the steel billets. Factors such as cooling rate, casting speed, and temperature control during the continuous casting process can affect the microstructure and overall homogeneity of the billets. Proper control and optimization of the process are necessary to ensure that the billets possess the desired metallurgical properties, such as a uniform grain structure and the absence of segregation or impurities. Moreover, the quality of steel billets directly impacts the efficiency and cost-effectiveness of subsequent steel processing operations. High dimensional accuracy in the billets reduces the need for excessive material removal during machining or shaping processes, resulting in higher material yield, reduced waste, and improved overall productivity. In conclusion, the quality of steel billets significantly influences the quality of the final steel product. The chemical composition, physical properties, and manufacturing process of the billets all play vital roles in determining the characteristics of the end product. By ensuring high-quality steel billets, manufacturers can produce steel products that meet industry standards, possess desired mechanical properties, and exhibit superior performance in various applications.

- Q: What are the potential applications of steel billets in the food and beverage industry?

- Steel billets have numerous potential applications in the food and beverage industry. One of the main uses is in the production of stainless steel equipment, such as tanks, vessels, and processing machinery. Stainless steel is a preferred material in the food and beverage industry due to its corrosion resistance, durability, and hygienic properties. Steel billets are often used to manufacture stainless steel pipes and fittings, which are essential components in food and beverage processing plants. These pipes and fittings are used for conveying fluids, gases, and food products, ensuring a safe and reliable transportation system. In addition, steel billets can be used to produce stainless steel bar and rod, which are used in various applications such as kitchen equipment, cutlery, and utensils. Stainless steel bar and rod are highly resistant to staining, rusting, and chemical corrosion, making them ideal for use in food preparation and serving. Furthermore, steel billets can be used to manufacture stainless steel sheets and plates, which are used for food storage and packaging. Stainless steel sheets and plates provide a hygienic and durable surface for food storage containers, countertops, and shelving units. They are easy to clean, resistant to bacterial growth, and do not react with acidic or alkaline food products. Overall, steel billets play a crucial role in the food and beverage industry by providing the necessary raw material to manufacture stainless steel equipment, pipes, fittings, bar, rod, sheets, and plates. The use of stainless steel enhances food safety, ensures product integrity, and contributes to the efficient and hygienic operation of food and beverage processing facilities.

- Q: What is the maximum temperature that a steel billet can withstand?

- The maximum temperature a steel billet can withstand is largely dependent on the specific type and grade of steel being used. However, as a general rule, most steels will lose their structural integrity and mechanical properties when exposed to temperatures above 800 degrees Celsius (1472 degrees Fahrenheit). At these elevated temperatures, steel experiences significant thermal expansion, resulting in distortion, warping, and eventual failure. In specialized applications, certain high-temperature alloys or superalloys have the ability to withstand even higher temperatures. These materials are purposefully designed to maintain their strength and durability under extreme heat, often surpassing 1000 degrees Celsius (1832 degrees Fahrenheit) or more. Nevertheless, it is crucial to understand that determining the maximum temperature a steel billet can endure should always involve consulting the technical data sheet specific to the material or seeking advice from experts in the field. Factors such as alloy composition, heat treatment, and intended usage can all contribute to establishing the maximum temperature limit for a steel billet.

- Q: How are steel billets used in the production of industrial valves?

- Steel billets are an essential component in the production of industrial valves. These billets serve as the raw material for manufacturing valve bodies, which are the main structural component of the valve. To begin the production process, steel billets are first heated to a specific temperature, usually through the use of a furnace. This heating process is crucial as it allows the billets to be malleable and easily shaped into the desired valve body design. Once the billets reach the required temperature, they are transferred to a special machine called a forging press. In the forging press, immense pressure is applied to the heated billet, causing it to take on the shape of a valve body. This process, known as forging, ensures that the valve body is strong, durable, and able to withstand the high pressures and temperatures of industrial applications. After the forging process, the valve bodies are then machined to achieve the final shape and dimensions. This involves using cutting tools to remove any excess material and refine the surface finish. The machined valve bodies are then inspected for quality assurance to ensure they meet the required specifications and standards. Once the valve bodies are ready, they undergo additional processes such as heat treatment and surface coating to enhance their strength, corrosion resistance, and overall performance. These treatments help to ensure that the valves can withstand harsh operating conditions and have a long service life. In summary, steel billets play a critical role in the production of industrial valves. They are heated and forged to create the valve bodies, which form the structural foundation of the valves. Through additional machining, heat treatment, and surface coating processes, the billets are transformed into high-quality valves that can effectively control the flow of fluids or gases in various industrial applications.

- Q: What is the role of steel billets in the manufacturing of hydraulic systems?

- Steel billets play a crucial role in the manufacturing of hydraulic systems. They serve as the raw material that is used to create various components and structures within these systems. Hydraulic systems rely on the use of pressurized fluid to transmit power and control mechanical motion. Therefore, the components within these systems need to be strong, durable, and resistant to corrosion and pressure. Steel billets provide the ideal starting material for manufacturing hydraulic system components due to their exceptional strength and toughness. They are typically made from carbon steel, which offers excellent mechanical properties such as high tensile strength and hardness. These properties ensure that the components can withstand the high pressures and forces experienced within hydraulic systems without deforming or failing. Furthermore, steel billets undergo various manufacturing processes such as forging, machining, and heat treatment to shape them into the desired components. These processes allow for the creation of intricate designs and precise dimensions, ensuring a proper fit and functionality within the hydraulic system. Moreover, steel billets are known for their excellent resistance to corrosion, which is crucial in hydraulic systems due to the presence of fluids and potential exposure to moisture. Corrosion can lead to component failure, leaks, and decreased system performance. The use of steel billets helps prevent such issues, ensuring the longevity and reliability of the hydraulic system. In summary, steel billets are essential in the manufacturing of hydraulic systems as they provide the necessary strength, durability, and corrosion resistance required for the components within these systems. Their versatility and ability to be shaped and processed make them an ideal material choice for creating reliable and efficient hydraulic systems.

- Q: How are steel billets used in the manufacturing of railway components?

- Steel billets are an essential raw material used in the manufacturing of railway components. These billets serve as the starting point for the production of various components such as rails, wheels, axles, and other structural parts. To begin with, steel billets are heated in a furnace to a specific temperature to make them more malleable and easier to shape. Once heated, the billets are then passed through a series of rolling mills, where they are progressively shaped into the desired form. For instance, to manufacture railway tracks, the heated billets are rolled and shaped into long continuous bars of steel known as rails. These rails are then cut to the required length and undergo further processes such as straightening, grinding, and drilling to meet the necessary specifications. Similarly, steel billets are also used in the manufacturing of railway wheels and axles. The heated billets are rolled and shaped into round bars, which are then further processed to form the wheel and axle components. These components undergo additional processes such as heat treatment, machining, and testing to ensure their strength, durability, and ability to withstand the heavy loads and stresses associated with railway operations. Furthermore, steel billets are utilized in the production of other railway components such as couplers, buffers, and suspension systems. These billets are shaped and processed according to the specific requirements of each component to ensure their proper functioning and compatibility with the overall railway system. In summary, steel billets are a critical ingredient in the manufacturing of railway components. They are transformed through heating and rolling processes to create various parts such as rails, wheels, axles, and other structural elements. These components are then further processed and tested to ensure their quality, reliability, and compliance with the demanding standards of the railway industry.

- Q: How do steel billets contribute to the overall safety of a structure?

- Steel billets contribute to the overall safety of a structure by providing a strong and durable material for construction. The high strength and toughness of steel billets make them resistant to external forces such as earthquakes, wind, and heavy loads. Additionally, steel billets have excellent fire resistance, as they do not burn or release toxic gases when exposed to high temperatures. This ensures the structural integrity of the building during a fire. Moreover, steel billets can be easily fabricated into various shapes and sizes, allowing for precise engineering and construction, which further enhances the safety and stability of the structure.

Send your message to us

High quality steel billet product Q195 Q35

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords