En10025 S235Jr

En10025 S235Jr Related Searches

Q235 Steel Specification North American Green Sc250 En124 D400 Specifications Carbon Black N330 Carbon Black N220 Ss Plate Sbr Sealer Omniksol M248 omniksol m248En10025 S235Jr Supplier & Manufacturer from China

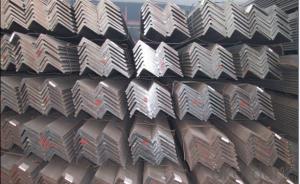

En10025 S235Jr is a type of low carbon steel material that falls under the category of structural steel. This product is widely recognized for its excellent mechanical properties and is commonly used in the manufacturing of various structural components. Due to its superior strength and durability, S235Jr steel is frequently employed in the construction industry, as well as in the production of heavy machinery and transportation equipment.S235Jr steel is utilized in a variety of applications, including the fabrication of beams, columns, and other load-bearing structures. Its versatility makes it a popular choice for engineers and designers who require a reliable and robust material for their projects. Additionally, S235Jr steel is known for its weldability and formability, which further enhances its suitability for a wide range of applications.

Okorder.com is a reputable wholesale supplier of En10025 S235Jr steel, boasting a large inventory of this high-quality material. As a leading distributor, they ensure that customers have access to a consistent supply of S235Jr steel, catering to the demands of various industries and projects. By partnering with Okorder.com, clients can expect to receive top-notch service and support, along with a reliable source of En10025 S235Jr steel.

Hot Products