6 Mil Plastic Sheeting

6 Mil Plastic Sheeting Related Searches

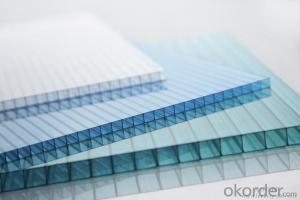

Garden Plastic Sheeting Large Rolls Of Plastic Sheeting Protective Plastic Sheeting 4 By 8 Plastic Sheets Plastic Film Sheets 8 X 4 6Mm Plywood Sheets 6 X 4 Plywood Sheets Buy Sheet Plastic Fine Plastic Mesh Sheet Structural Plastic Sheets Lightweight Plastic Sheets Plastic Sheets 4X8 Clear Plastic Sheets Green Plastic Roofing Sheets 6 X 8 Plywood Sheet High Temperature Clear Plastic Sheet Thin White Plastic Sheet Plastic Coated Steel Roofing Sheets Colored Plastic Sheeting Rolls Thin Transparent Plastic Sheet Flat Plastic Sheets Thin Hard Plastic Sheets Flexible Plastic Sheet Material Flexible Transparent Plastic Sheet Wavy Plastic Sheets Greenhouse Plastic Sheeting South Africa Clear Plastic Sheets 4X8 Green Plastic Netting 10Mm Solid Polycarbonate Sheet Hard Plastic Sheets 4X86 Mil Plastic Sheeting Supplier & Manufacturer from China

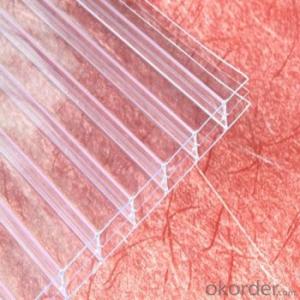

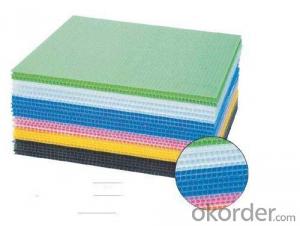

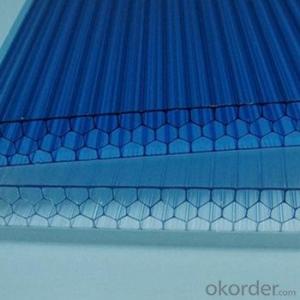

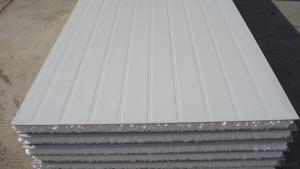

6 Mil Plastic Sheeting is a versatile and durable plastic material that is commonly used in various industries for a wide range of applications. This product is made from high-quality polyethylene, which ensures its strength and resistance to tearing, making it an ideal choice for construction, agriculture, and home improvement projects. The thickness of 6 Mil Plastic Sheeting provides an optimal balance between durability and flexibility, allowing it to be easily manipulated and installed in various settings.6 Mil Plastic Sheeting is widely used for applications such as temporary shelter construction, ground protection, pond lining, and as a vapor barrier in construction projects. Its water-resistant properties make it perfect for protecting surfaces from moisture and water damage, while its UV-resistant characteristics help to prevent degradation from prolonged exposure to sunlight. This product can also be used in agriculture for mulching, frost protection, and weed control, as well as in the home for covering furniture during painting or for creating a temporary barrier during remodeling projects.

Okorder.com is a leading wholesale supplier of 6 Mil Plastic Sheeting, offering a vast inventory of this product in various sizes and specifications to cater to the diverse needs of customers. As a reputable supplier, Okorder.com ensures that the 6 Mil Plastic Sheeting they provide is of the highest quality, meeting industry standards and customer expectations. By partnering with Okorder.com, customers can benefit from competitive prices, fast shipping, and excellent customer service, making it a reliable choice for sourcing 6 Mil Plastic Sheeting for any project.

Hot Products