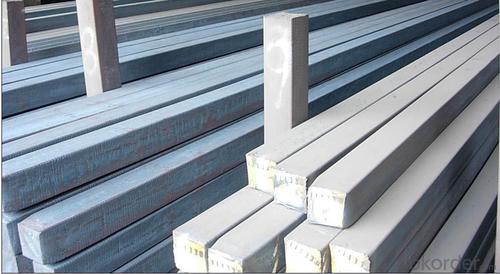

Square Steel Billet Q235 Grade Prime Quality 4#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 4#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 4#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 4#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 4#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 4#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets inspected for internal defects?

- Various non-destructive testing (NDT) techniques are utilized to inspect steel billets for internal defects. Ultrasonic testing (UT) is a common method wherein high-frequency sound waves are employed to detect flaws within the billet. By sending ultrasonic waves into the billet and analyzing the reflected waves, any internal flaws can be identified. UT has the capability to detect defects such as cracks, voids, inclusions, and other irregularities. Another technique used is magnetic particle inspection (MPI), which is particularly effective for identifying surface and near-surface defects in ferromagnetic materials like steel. By applying a magnetic field to the billet and spreading iron particles over its surface, any defects will cause the particles to form visible indications, thereby providing a clear indication of internal flaws. Liquid penetrant testing (PT) is another widely employed method for inspecting steel billets. This process involves applying a liquid dye to the billet's surface and allowing it to penetrate any surface-breaking defects. After a designated time, excess dye is removed and a developer is applied. The developer draws out the penetrant from any defects, making them visible under suitable lighting conditions. Furthermore, radiographic testing (RT) can be utilized to detect internal defects in steel billets. This method utilizes X-rays or gamma rays to capture images of the billet's internal structure. As the radiation passes through the billet, a film or digital detector records the transmitted radiation. Any internal defects will appear as shadows on the image, facilitating their identification. In summary, a combination of these NDT techniques is often employed to ensure a comprehensive inspection of steel billets for internal defects. This aids in maintaining the quality and integrity of the billets, ensuring they meet the necessary specifications and standards.

- Q: What are the factors that determine the lifespan of steel billets?

- Several factors influence the lifespan of steel billets. Firstly, the critical factor is the quality of the steel used during production. Steel containing high levels of impurities or inconsistent composition may have a shorter lifespan. The manufacturing process also has a significant impact. If the steel billets are not heated, cooled, or rolled properly, they may develop internal stresses or defects that can lead to premature failure. Furthermore, environmental factors affect the lifespan of steel billets. Exposure to corrosive substances, such as chemicals or moisture, can result in corrosion and degradation of the steel. Additionally, extreme temperatures can cause thermal expansion and contraction, leading to fatigue or cracking of the billets over time. The handling and storage of steel billets are equally important. Mishandling, dropping, or subjecting them to excessive impact can lead to deformation or microstructural changes that reduce their lifespan. Proper storage conditions, including protection from moisture, direct sunlight, and extreme temperature fluctuations, can help preserve the integrity of the billets. Regular maintenance and inspection also contribute to determining the lifespan of steel billets. Detecting and repairing defects or damages in a timely manner can prevent further deterioration and extend their lifespan. In conclusion, the lifespan of steel billets is determined by the quality of the steel, the manufacturing process, environmental conditions, handling and storage practices, as well as maintenance and inspections.

- Q: What are the different types of surface finishes available for steel billets?

- The different types of surface finishes available for steel billets include hot rolled, cold rolled, pickled and oiled, and galvanized finishes.

- Q: How is the quality of steel billets determined?

- The quality of steel billets is determined through various factors including chemical composition, physical properties, and visual inspection. Chemical composition analysis involves measuring the levels of different elements present in the billets such as carbon, manganese, and sulfur, as well as checking for any impurities. Physical properties such as tensile strength, hardness, and toughness are tested to ensure the billets meet the required specifications. Visual inspection is also performed to identify any defects like cracks, surface abnormalities, or unevenness. Combining these assessments helps determine the overall quality of steel billets.

- Q: What is the role of steel billets in the manufacturing of construction machinery?

- Steel billets play a crucial role in the manufacturing of construction machinery as they serve as the raw material for producing various components and structures. These billets are initially heated and then shaped or machined into different forms such as plates, beams, or rods, which are essential in constructing the frames, chassis, and other structural parts of construction machinery. The high strength and durability of steel make it ideal for withstanding heavy loads and harsh working conditions, ensuring the reliability and longevity of construction machinery.

- Q: What are the different types of cutting techniques used for steel billets?

- There are several different cutting techniques used for steel billets, depending on the specific requirements of the project. Some common cutting techniques include: 1. Sawing: This is one of the most traditional and widely used cutting techniques. Sawing involves using a saw blade to cut through the steel billet. It can be done manually or with the help of automated sawing machines. Sawing is suitable for cutting both small and large steel billets. 2. Flame Cutting: Also known as oxy-fuel cutting, this technique involves using a flame torch to heat the steel to its kindling temperature and then introducing a jet of oxygen to burn through the metal. Flame cutting is commonly used for cutting thicker steel billets and can be performed manually or with CNC-controlled equipment. 3. Plasma Cutting: Plasma cutting utilizes a high-velocity jet of ionized gas to melt and blow away the steel. This technique is particularly effective for cutting steel billets with complex shapes or contours. Plasma cutting is often automated and can produce clean and precise cuts. 4. Waterjet Cutting: Waterjet cutting involves using a high-pressure jet of water combined with abrasive particles to cut through the steel billet. This technique is ideal for cutting materials that are sensitive to heat, as it produces minimal heat-affected zones. Waterjet cutting can also handle various thicknesses and shapes of steel billets. 5. Laser Cutting: Laser cutting utilizes a high-powered laser beam to melt and vaporize the steel, creating a clean and precise cut. This technique is highly accurate and can be used for cutting intricate shapes and designs. Laser cutting is often automated and commonly used in industrial settings. It is important to consider factors such as the desired precision, speed, material thickness, and budget to choose the most appropriate cutting technique for steel billets. Each cutting technique has its own advantages and limitations, and selecting the right one can significantly impact the quality and efficiency of the cutting process.

- Q: What are the main challenges in the supply chain management of steel billets?

- There are several main challenges in the supply chain management of steel billets. 1. Demand fluctuations: The steel industry is highly sensitive to economic cycles and changes in global demand. Fluctuations in demand can lead to imbalances in the supply chain, causing excess inventory or shortages of steel billets. This uncertainty makes it challenging for supply chain managers to accurately forecast demand and optimize production and inventory levels. 2. Transportation and logistics: Steel billets are heavy and bulky, making transportation and logistics a major challenge. Efficient transportation networks need to be established to ensure timely delivery of steel billets to customers. Moreover, the handling and storage of steel billets require specialized equipment and facilities, which can add complexity and cost to the supply chain. 3. Supply chain visibility: Lack of visibility and transparency across the supply chain can lead to inefficiencies and delays. It is crucial for supply chain managers to have real-time information on inventory levels, production status, and transportation schedules. This enables them to make informed decisions and mitigate any potential disruptions in the supply chain. 4. Quality control: Maintaining consistent quality of steel billets throughout the supply chain is vital. Steel billets are often produced by different manufacturers, and variations in quality can occur. Supply chain managers need to implement robust quality control processes to ensure that only high-quality billets are delivered to customers. This may involve regular inspections, testing, and strict adherence to industry standards. 5. Sustainability and environmental concerns: The steel industry is under increasing pressure to reduce its carbon footprint and adopt sustainable practices. Supply chain managers face the challenge of implementing environmentally friendly processes and sourcing steel billets from suppliers that adhere to sustainable practices. This may involve evaluating the environmental impact of transportation methods, optimizing energy consumption during production, and ensuring responsible sourcing of raw materials. In summary, the main challenges in the supply chain management of steel billets include demand fluctuations, transportation and logistics, supply chain visibility, quality control, and sustainability concerns. Overcoming these challenges requires effective planning, collaboration with suppliers and customers, and the use of advanced technologies to improve visibility and optimize processes.

- Q: How are steel billets used in the production of industrial furnaces?

- Steel billets are used in the production of industrial furnaces as the primary raw material for constructing the furnace structure and components. These billets are melted and molded into various shapes and sizes to create the furnace body, walls, doors, and other necessary parts. The high strength and heat resistance of steel make it ideal for withstanding the extreme temperatures and harsh conditions within the furnace, ensuring its durability and longevity.

- Q: How do steel billets contribute to the overall vibration resistance of a structure?

- The specific characteristics of steel billets make a significant contribution to the overall vibration resistance of a structure. Primarily, steel is a dense and rigid material, giving it a high natural frequency. This allows steel billets to effectively absorb and dissipate energy from external vibrations, surpassing the capabilities of other materials. Additionally, steel billets exhibit exceptional damping properties. Damping refers to a material's ability to diminish the magnitude of vibrations over time. Due to their density and rigidity, steel billets can rapidly absorb and dissipate vibrations, thus preventing their spread throughout the structure. This aids in reducing overall vibration levels and subsequently enhances the structure's resistance to vibrations. Furthermore, steel billets possess remarkable tensile strength and stiffness, enabling them to withstand deformation caused by dynamic loads. Consequently, when subjected to vibration forces, steel billets retain their shape and structural integrity, minimizing the risk of failure or damage. The high tensile strength of steel also allows it to endure external forces without enduring substantial deformation or permanent harm. Moreover, steel billets can be specifically designed and manufactured to precise dimensions and shapes, facilitating their optimal integration into various structural components. This ensures that steel billets are positioned optimally within the structure, thereby enhancing their capabilities to resist vibrations. In summary, steel billets contribute to a structure's overall vibration resistance by effectively absorbing and dissipating vibrations, resisting deformation, and maintaining structural integrity. Through these properties, steel billets mitigate the impact of external vibrations, ensuring the durability and stability of the structure.

- Q: What are the main factors affecting the corrosion resistance of steel billets?

- Steel billets' corrosion resistance is determined by several main factors: the steel's composition, impurities present, surface condition, and the surrounding environment. To begin with, the steel's composition significantly affects its corrosion resistance. Stainless steels, for instance, possess high levels of chromium and other alloying elements that generate a protective oxide layer on the surface, granting excellent corrosion resistance. Conversely, carbon steels have lower resistance due to their increased carbon content and lack of alloying elements. Furthermore, the presence of impurities in the steel greatly impacts its corrosion resistance. Impurities like sulfur, phosphorous, and non-metallic inclusions act as corrosion initiation sites, leading to localized corrosion and reduced overall resistance. Consequently, managing impurities' presence and distribution during steel billet production is vital to improve corrosion resistance. Moreover, the surface condition of steel billets plays a crucial role in their corrosion resistance. A smooth and clean surface supports the formation of a protective oxide layer, acting as a barrier against corrosive substances. Conversely, rough or contaminated surfaces increase corrosion risk due to the larger surface area and potential for localized corrosion. Lastly, the surrounding environment has a significant influence on steel billets' corrosion resistance. Factors such as humidity, temperature, pH, and the presence of corrosive substances like acids, salts, or pollutants can accelerate corrosion. For instance, steel billets in high humidity or exposed to corrosive chemicals are more vulnerable to corrosion compared to those in dry or less corrosive environments. In conclusion, the corrosion resistance of steel billets relies on their composition, impurities present, surface condition, and surrounding environment. Considering these factors during steel billet production and handling is essential to ensure their long-term durability and resistance against corrosion.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 4#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords