Steel Billet Price Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billet Price Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

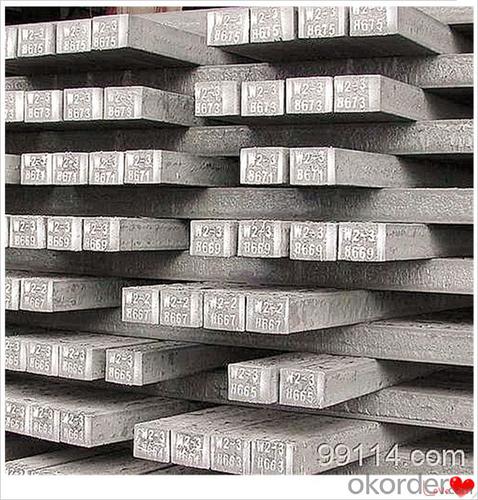

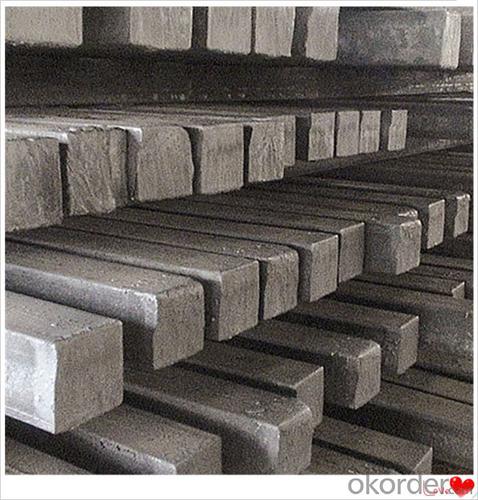

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

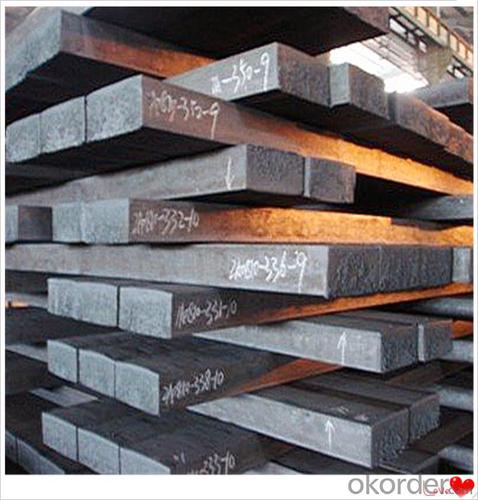

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

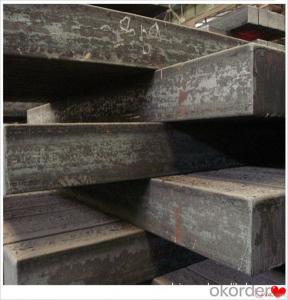

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

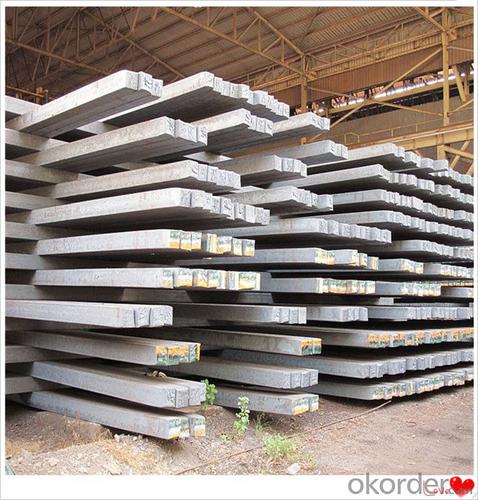

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

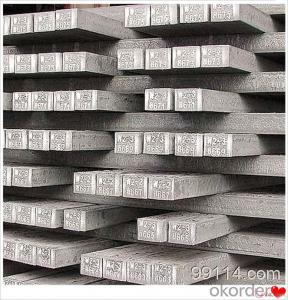

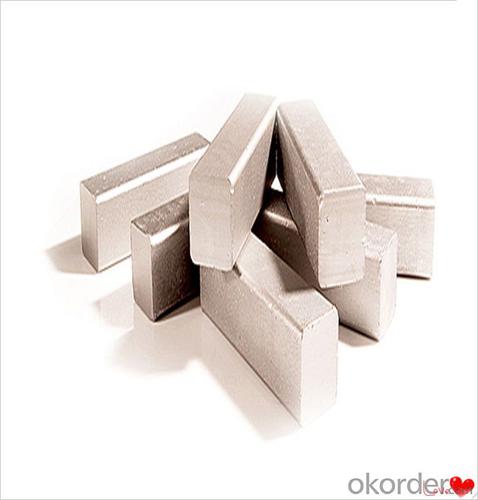

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What are the different shapes and forms of steel billets?

- Steel billets come in various shapes and forms, including square, rectangular, round, and hexagonal. These shapes and forms are designed to meet specific requirements and applications in various industries, such as construction, manufacturing, and engineering.

- Q: Can steel billets be coated for improved corrosion resistance?

- Yes, steel billets can be coated with various materials such as zinc, aluminum, or polymer coatings to enhance their corrosion resistance.

- Q: What is carbon accumulation?

- Generally refers to the polycarbonate, PC, is a kind of thermoplastic plastics, good transparency, good mechanical properties, surface hardness, common uses such as CD, plastic glasses, a fence, protective window, public places, vacuum cleaners, coffee machine, juicer barrel, refrigerator shelf, pure such as the bucket.

- Q: How are steel billets recycled at the end of their lifespan?

- Steel billets are recycled at the end of their lifespan through a process called steel scrap recycling. First, the billets are collected from various sources such as construction sites and manufacturing plants. They are then sorted, cleaned, and melted in a furnace to remove impurities. The molten steel is then cast into new billets or other steel products, ensuring that the steel billets are reused and not wasted, reducing the need for virgin steel production and conserving resources.

- Q: How are steel billets reheated before rolling or forging?

- Steel billets are reheated before rolling or forging by passing them through a furnace or a reheating furnace, which raises their temperature to a specific range. This process, known as billet reheating, is crucial as it improves the billets' malleability, making them easier to shape and work with during the subsequent rolling or forging operations.

- Q: What are the factors affecting the price of steel billets?

- There are several factors that can affect the price of steel billets. 1. Supply and demand: Like any other commodity, the price of steel billets is influenced by the balance between supply and demand. If the demand for steel billets is high and the supply is limited, the price will increase. Conversely, if the supply exceeds the demand, the price will decrease. 2. Raw material costs: The cost of the raw materials used to produce steel billets, such as iron ore and coal, can significantly impact the price. Fluctuations in the prices of these raw materials can lead to changes in the cost of production, which in turn affects the price of steel billets. 3. Energy prices: The production of steel billets requires a significant amount of energy, particularly in the form of electricity and fuel. Therefore, changes in energy prices can have a direct impact on the price of steel billets. For example, if energy prices increase, the cost of production for steel billets will also rise, leading to a higher price. 4. Transportation costs: The cost of transporting steel billets from the manufacturing plant to the market can also affect the final price. Factors such as fuel prices, distance, and transportation infrastructure can impact the transportation costs and subsequently influence the price of steel billets. 5. Government regulations and trade policies: Government regulations, such as import/export duties, tariffs, and quotas, can have a significant impact on the price of steel billets. These policies can restrict or facilitate the movement of steel billets between countries, affecting the supply and demand dynamics and, consequently, the price. 6. Currency exchange rates: Steel billets are traded globally, and fluctuations in currency exchange rates can impact their price. If the currency in which steel billets are traded weakens against other currencies, the price of steel billets may increase to compensate for the decreased value of the currency. 7. Market speculation and investor sentiment: The price of steel billets, like any other commodity, can also be influenced by market speculation and investor sentiment. Factors such as economic indicators, geopolitical events, and investor expectations can drive buying or selling behavior, leading to price fluctuations. It is important to note that these factors are interconnected and can interact with each other, creating a complex and dynamic market for steel billets.

- Q: What is the role of steel billets in the production of automotive components?

- The role of steel billets in the production of automotive components is to serve as the raw material for forging or casting processes. These billets are heated and shaped into various automotive parts, such as engine components, chassis parts, and suspension systems. Steel billets provide the necessary strength and durability required for these components to withstand the demanding conditions and stresses encountered in automotive applications.

- Q: What are the challenges faced in the distribution and supply chain of steel billets?

- Some challenges faced in the distribution and supply chain of steel billets include transportation and logistics issues, such as the need for specialized equipment and efficient handling processes due to the heavyweight and bulky nature of steel billets. Additionally, ensuring timely delivery and managing inventory levels can be challenging due to various factors like unpredictable demand fluctuations and production delays. Quality control and inspection of steel billets during transit and storage is also crucial to prevent damage or deterioration. Lastly, coordinating with multiple stakeholders, including suppliers, manufacturers, distributors, and customers, requires effective communication and collaboration to maintain a smooth and reliable supply chain.

- Q: What are the main factors affecting the impact toughness of steel billets?

- The impact toughness of steel billets can be affected by several main factors. Firstly, the toughness of the steel is significantly influenced by its chemical composition. Alloying elements like carbon, manganese, and nickel can enhance toughness. Higher carbon content increases hardness but decreases impact toughness. On the other hand, the addition of manganese and nickel promotes the formation of fine-grained structures, improving toughness. Secondly, the heat treatment process used during steel billet production plays a crucial role in their toughness. Annealing and quenching processes refine the microstructure of the steel, making it more resistant to cracking and brittle fracture. However, improper heat treatment or rapid cooling rates can lead to the formation of undesirable phases or microstructural defects, reducing impact toughness. Thirdly, the presence of impurities and inclusions in the steel also affects its toughness. Non-metallic inclusions, such as sulfides and oxides, act as stress concentrators and initiate crack propagation during impact loading. Therefore, steel with lower impurity levels and cleaner inclusion content exhibits higher toughness. Moreover, the grain size of the steel significantly influences its toughness. Finer grain sizes improve toughness due to the increased number of grain boundaries that act as barriers to crack propagation. Thus, steel billets with smaller grain sizes are more resistant to brittle fracture. Lastly, the mechanical working processes like hot rolling or forging can affect the toughness of steel billets. These processes induce deformation and strain hardening, increasing strength but potentially decreasing toughness. Careful control of deformation parameters is necessary to balance strength and toughness in steel billets. To summarize, the impact toughness of steel billets is influenced by various factors, including chemical composition, heat treatment, impurities and inclusions, grain size, and mechanical working processes. Understanding and optimizing these factors are crucial in producing steel billets with the desired toughness for specific applications.

- Q: How do steel billets contribute to the manufacturing of industrial machinery?

- Steel billets play a crucial role in the manufacturing of industrial machinery. These billets are essentially semi-finished steel products that are formed into a specific shape and size. They serve as the raw material for producing various components and parts used in industrial machinery. Firstly, steel billets provide the necessary strength and durability required for industrial machinery. The high tensile strength and toughness of steel make it ideal for withstanding heavy loads, vibrations, and extreme conditions that machinery often encounters. By using steel billets, manufacturers can ensure that the machinery they produce is capable of withstanding these demanding conditions, thereby increasing its reliability and longevity. Secondly, steel billets can be easily molded and shaped into different forms, allowing for the production of complex and intricate components. Industrial machinery often requires precision-engineered parts that are tailored to specific functions and applications. Steel billets can be cast or forged into these intricate shapes, ensuring that the machinery operates with optimal efficiency and accuracy. Additionally, steel billets offer excellent machinability, meaning they can be easily cut, drilled, and shaped using various machining techniques. This makes it possible to create intricate details and tolerances required for the precise functioning of industrial machinery. The ability to machine steel billets with precision allows manufacturers to produce components that fit together seamlessly, minimizing any potential performance issues. Moreover, steel billets provide a cost-effective solution for manufacturing industrial machinery. Steel is readily available and has a relatively low cost compared to other materials. Its superior strength-to-weight ratio also allows manufacturers to design machinery that is lighter in weight without compromising its structural integrity. This not only reduces manufacturing costs but also makes the machinery more portable and easier to transport. Furthermore, steel billets offer excellent corrosion resistance, which is crucial for industrial machinery that operates in harsh environments. The protective oxide layer that forms on the surface of steel billets helps prevent rust and corrosion, ensuring that the machinery remains in optimal working condition even in challenging conditions. In conclusion, steel billets are essential in the manufacturing of industrial machinery due to their strength, durability, machinability, cost-effectiveness, and corrosion resistance. These properties enable manufacturers to produce reliable, precise, and long-lasting machinery that can withstand demanding industrial applications.

Send your message to us

Steel Billet Price Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords