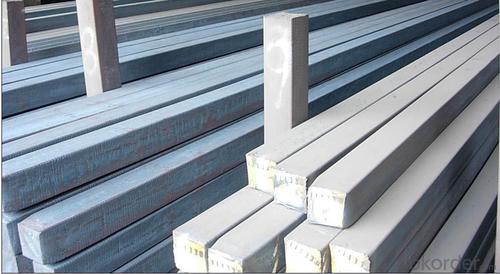

Square Steel Billet Q235 Grade Prime Quality 3#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 3#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 3#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 3#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 3#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 3#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How do steel billets compare to other metal billets?

- Steel billets are generally considered superior to other metal billets due to their high strength, durability, and versatility. Steel billets offer excellent weldability, machinability, and resistance to corrosion, making them suitable for a wide range of applications in industries such as construction, automotive, and manufacturing. Additionally, steel billets can be easily modified and shaped into various forms, allowing for efficient and precise fabrication processes.

- Q: What are the main factors affecting the dimensional accuracy of steel billets?

- The main factors affecting the dimensional accuracy of steel billets include the quality of the raw materials used, the temperature and cooling rate during the casting process, the design and condition of the casting equipment, and the skill and experience of the operators.

- Q: How are steel billets measured?

- To ensure accurate dimensions and specifications, various techniques and tools are employed in measuring steel billets. One commonly utilized approach involves the utilization of calipers or micrometers. These tools enable precise measurements of the billet's diameter, length, and other necessary dimensions. Apart from physical measurements, non-destructive testing methods like ultrasonic testing or eddy current testing are also applied to steel billets. These techniques effectively identify any internal defects or inconsistencies within the billet, thus guaranteeing its quality and integrity. Moreover, the mass of steel billets is often determined through weighing. Depending on the size and weight of the billet, different weighing scales or load cells are employed for this purpose. The weight measurement plays a vital role in determining the billet's mass per unit length, which is crucial for calculating its density and other mechanical properties. In summary, the measurement of steel billets is an essential stage in the manufacturing process. It ensures that the billets meet the necessary specifications for further processing and utilization in diverse industries such as construction, automotive, and manufacturing.

- Q: What are the main differences between hot rolled and cold rolled steel billets?

- The main differences between hot rolled and cold rolled steel billets lie in the manufacturing process and the resulting properties of the finished product. Hot rolled steel billets are produced by heating the steel to a high temperature and then rolling it through large rollers. This process allows for the steel to be shaped and formed easily, resulting in a product with a rougher surface and less precise dimensions. Hot rolled steel billets also tend to have a scaled surface due to the high temperature involved in the manufacturing process. On the other hand, cold rolled steel billets are produced by cooling the steel to room temperature and then passing it through rollers at a lower temperature. This process not only results in a smoother surface finish but also allows for tighter tolerances and more precise dimensions. Cold rolled steel billets have a more uniform appearance and are often used in applications that require a higher degree of precision and accuracy. In terms of mechanical properties, hot rolled steel billets generally have a lower strength and hardness compared to cold rolled steel billets. Cold rolled steel billets also tend to have improved surface hardness and a higher degree of dimensional stability. Overall, the main differences between hot rolled and cold rolled steel billets are the manufacturing process, surface finish, dimensional accuracy, and mechanical properties. Hot rolled steel billets are more easily shaped and formed, while cold rolled steel billets have a smoother surface finish and more precise dimensions. The choice between the two depends on the specific requirements of the application.

- Q: How are steel billets used in the manufacturing of aerospace components?

- Steel billets are used in the manufacturing of aerospace components as they are the raw material that undergoes various processes like forging, machining, and heat treatment to shape and strengthen them into specific aerospace parts such as engine components, landing gear, and structural parts.

- Q: How do steel billets contribute to sustainable construction?

- Steel billets play a crucial role in sustainable construction through various means: 1. Energy efficiency: By utilizing electric arc furnaces, steel billets require less energy than traditional manufacturing methods. This leads to decreased greenhouse gas emissions and a reduced carbon footprint. 2. Recyclability: Steel billets can be recycled multiple times without losing their mechanical properties, making steel one of the most recycled materials worldwide. This conserves natural resources, reduces waste disposal, and lessens the need for new steel production. 3. Strength and durability: With their exceptional strength and durability, steel billets are an excellent choice for sustainable construction. Their structural integrity ensures long-lasting buildings, minimizing the need for frequent repairs or replacements and extending the lifespan of structures. 4. Versatility: Steel billets can be shaped and formed into various structural components, allowing for flexible design and construction. This adaptability enables the construction of sustainable buildings that can easily accommodate changing requirements, reducing the necessity for new construction. 5. Resilience to natural disasters: Steel billets exhibit outstanding resistance to seismic forces, hurricanes, and other natural disasters. This makes them ideal for constructing buildings in disaster-prone regions, thereby enhancing the safety and resilience of the built environment. 6. Reduced construction time: The prefabricated nature of steel billets enables faster construction, minimizing disruption to the environment and local communities. Additionally, prefabricated steel components can be easily dismantled and reused, further enhancing sustainability. In conclusion, steel billets contribute significantly to sustainable construction by reducing energy consumption, offering recyclability, providing strength and durability, allowing for design versatility, resisting natural disasters, and reducing construction time. By incorporating steel billets into construction projects, we can create environmentally-friendly and long-lasting structures that promote sustainability in the built environment.

- Q: How are steel billets used in the manufacturing of automotive parts?

- Steel billets are an essential raw material used in the manufacturing of automotive parts. These billets, which are typically short, solid pieces of steel, serve as the starting point for various automotive components. Firstly, steel billets are heated and then passed through a series of rolling mills to convert them into different shapes and sizes. This process, known as hot rolling, allows the steel billets to be transformed into bars, rods, or sheets that can be further machined or formed into automotive parts. The automotive industry relies heavily on steel billets to produce a wide range of components, such as engine blocks, crankshafts, suspension parts, and chassis frames. These parts require high strength and durability to withstand the demanding conditions of vehicles. Engine blocks, for example, are typically made from cast iron or aluminum alloys produced from steel billets. The billets are melted and poured into molds to create the desired shape, which forms the foundation of the engine. Similarly, crankshafts, which transfer power from the engine to the wheels, are often forged from steel billets to ensure strength and precision. Suspension parts, such as control arms and torsion bars, also rely on steel billets for their manufacturing. These parts need to withstand the forces and impact of the road, and steel provides the necessary strength and resilience. Billets are machined and shaped to create the required geometry and then assembled with other components to form the suspension system. Additionally, steel billets are used in the production of chassis frames, which provide the structural integrity and support for the entire vehicle. These frames are typically made from steel tubes or sections formed from billets. The billets are shaped, welded, and joined together to create a strong and rigid framework that gives stability and ensures safety. In conclusion, steel billets play a crucial role in the manufacturing of automotive parts. With their versatility and strength, they are transformed into various components that form the backbone of vehicles, ensuring durability, performance, and safety on the road.

- Q: What are the main factors affecting the corrosion resistance of alloy steel billets?

- The corrosion resistance of alloy steel billets can be influenced by several key factors. Firstly, the resistance to corrosion is determined by the composition of the alloy steel. Steels with a higher percentage of elements like chromium, nickel, and molybdenum tend to have improved corrosion resistance compared to steels with lower alloy content. Secondly, the application of protective surface coatings or finishes can greatly enhance the corrosion resistance of alloy steel billets. Coatings such as zinc or epoxy act as a barrier between the metal surface and the corrosive environment, preventing direct contact with corrosive agents. Furthermore, the corrosion resistance of alloy steel billets can be affected by the manufacturing process. Proper heat treatment and quenching processes can improve the microstructure of the alloy, resulting in a more corrosion-resistant material. The environment in which the alloy steel billets are exposed is also a crucial factor. Elements like temperature, humidity, pH levels, and the presence of corrosive substances can all impact corrosion resistance. For instance, high temperatures or acidic environments can accelerate corrosion, while dry or neutral conditions may have minimal impact. Lastly, the design and maintenance of structures or equipment made from alloy steel billets can influence their corrosion resistance. Considerations like avoiding moisture accumulation in sharp corners or crevices can help minimize the risk of corrosion. Regular inspection, cleaning, and maintenance can also prevent corrosion by promptly addressing any issues. To summarize, the key factors affecting the corrosion resistance of alloy steel billets include the steel's composition, the presence of protective coatings, the manufacturing process, the environmental conditions, and the design and maintenance practices. By considering these factors, manufacturers and users can ensure optimal corrosion resistance in various applications of alloy steel billets.

- Q: Can steel billets be used in the production of electrical appliances?

- Yes, steel billets can be used in the production of electrical appliances. Steel billets are semi-finished products that are typically used to produce various steel products, including electrical appliances. The steel billets can be further processed and shaped into different components required for electrical appliances, such as casings, frames, brackets, and other structural parts. The use of steel provides strength, durability, and corrosion resistance, making it suitable for the demanding requirements of electrical appliances. Additionally, steel is a widely available and cost-effective material, making it a preferred choice for manufacturing electrical appliances.

- Q: How are steel billets used in the production of aerospace parts?

- Steel billets are used in the production of aerospace parts as they serve as the starting material for forging or machining processes. These billets are heated, shaped, and then further processed to create the desired components, such as engine parts, landing gear components, or structural elements, which are crucial for the performance and safety of aerospace machinery.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 3#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords