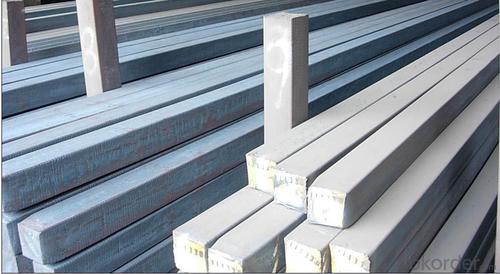

Square Steel Billet Q235 Grade Prime Quality 5#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 5#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 5#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 5#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 5#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 5#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the main factors affecting the cost of steel billets?

- There are several main factors that can affect the cost of steel billets. 1. Raw material costs: The cost of the raw materials used to produce steel billets, such as iron ore and scrap metal, can have a significant impact on the overall cost. Fluctuations in the prices of these raw materials in the global market can cause the cost of steel billets to rise or fall. 2. Production and processing costs: The cost of manufacturing steel billets includes various production and processing expenses, such as energy costs, labor costs, and maintenance costs. These costs can vary depending on factors such as the efficiency of production processes, the availability of skilled labor, and the cost of energy sources. 3. Supply and demand dynamics: The balance between supply and demand for steel billets in the market can heavily influence their cost. If there is a high demand for steel billets and limited supply, the prices can increase. Conversely, if there is excess supply and low demand, the prices can decrease. 4. Market competition: The level of competition among steel producers can also impact the cost of steel billets. In a competitive market, where multiple producers are vying for customers, the prices may be driven down as producers try to attract buyers. Conversely, in a less competitive market, producers may have more pricing power, leading to higher prices. 5. Trade policies and tariffs: Government policies and trade barriers, such as import tariffs and quotas, can affect the cost of steel billets. These measures can either protect domestic steel producers by making imported steel more expensive or create opportunities for cheaper imports, depending on the specific policies in place. 6. Currency exchange rates: Since steel billets are traded globally, fluctuations in currency exchange rates can impact their cost. A stronger domestic currency can make imported steel billets cheaper, while a weaker domestic currency can make them more expensive. 7. Transportation and logistics: The cost of transporting steel billets from the production facility to the end-user can also influence their overall cost. Factors such as distance, transportation mode, and fuel prices can impact the transportation expenses, which can, in turn, affect the final price of steel billets. It is important to note that these factors can interact with each other, and their impact on the cost of steel billets can vary depending on the specific market conditions and industry dynamics.

- Q: How are steel billets used in the production of heat exchangers?

- Steel billets are an essential component in the production of heat exchangers. Heat exchangers are devices that transfer heat between two or more fluids, such as air and water, without them coming into direct contact. Steel billets, which are semi-finished metal products, serve as the raw material for manufacturing the various components of heat exchangers. Firstly, steel billets are used to create the tubes and pipes that form the primary framework of heat exchangers. These tubes are designed to withstand high pressures and temperatures while efficiently transferring heat. Steel, with its high strength and thermal conductivity, is an ideal material for this purpose. Next, the steel billets are processed through various techniques such as hot rolling, forging, or extrusion to shape them into the required dimensions. This process ensures that the tubes and pipes have the desired diameter, thickness, and length, which are crucial factors in determining the heat transfer efficiency of the heat exchanger. Additionally, steel billets are also used to produce the fins and plates of heat exchangers. Fins are thin, elongated structures that increase the surface area of the heat exchanger, allowing for enhanced heat transfer. Steel billets are shaped and cut into fins, which are then attached to the tubes or plates. These fins provide additional contact points for heat transfer and help improve the overall efficiency of the heat exchanger. Moreover, steel billets are used in the production of headers and manifolds, which are crucial components for the distribution and collection of fluids within the heat exchanger. These headers ensure that the fluids flow through the tubes and fins in a controlled manner, maximizing heat transfer and minimizing pressure losses. The strength and durability of steel make it a suitable material for these critical components. In conclusion, steel billets play a vital role in the production of heat exchangers. They are used to manufacture the tubes, pipes, fins, headers, and manifolds, which are all essential components of a heat exchanger. The use of steel ensures the durability, strength, and thermal conductivity required for efficient heat transfer in these devices.

- Q: Can steel billets be used in the production of railway tracks?

- Yes, steel billets can be used in the production of railway tracks. Steel billets are commonly used as raw material for manufacturing various steel products, including railway tracks. The billets are first heated and then rolled into shape to create the required profile for the tracks. This process ensures the tracks have the necessary strength, durability, and dimensional accuracy to withstand the heavy loads and constant usage in railway operations.

- Q: How are steel billets used in the production of construction parts?

- Steel billets are an important raw material in the production of construction parts. They are essentially semi-finished steel products that are cast into square or rectangular shapes. These billets are then further processed and transformed into various construction components like beams, columns, rods, and bars. The first step in utilizing steel billets is heating them in a furnace to a temperature that allows for easy deformation and shaping. Once the billets reach the desired temperature, they are passed through a series of rolling mills, where they undergo hot rolling. This process involves repeatedly passing the billets through multiple pairs of rollers to gradually reduce their size and shape them into the required form, such as beams or rods. Hot rolling not only helps to shape the billets but also improves their mechanical properties, such as strength, toughness, and ductility. The resulting steel products are then cut to the desired lengths and further processed, if necessary, to meet specific construction requirements. These steel components made from billets are widely used in construction projects. For instance, beams made from steel billets are commonly used to provide structural support in buildings and bridges. They offer superior strength and load-bearing capacity, making them ideal for withstanding heavy loads and ensuring the overall stability of the structure. Steel rods and bars, on the other hand, are widely used in reinforced concrete construction. These components are embedded within the concrete to increase its tensile strength and prevent cracks from forming. They are essential in the construction of foundations, slabs, walls, and other structural elements that require added reinforcement. In summary, steel billets play a crucial role in the production of construction parts by serving as the starting point for the manufacturing process. Through hot rolling and subsequent processing, these billets are transformed into various steel components that are used to provide structural support, reinforcement, and durability in construction projects.

- Q: How are steel billets used in the production of railway components?

- Railway components rely heavily on steel billets during the production process. These billets, which are essentially semi-finished steel products, serve as the foundation for manufacturing various railway components such as rails, wheels, axles, and structural parts. To create railway components, steel billets are first heated to a specific temperature, enhancing their malleability. This crucial heating process enables easy shaping and forming of the steel into the desired component. Once the billets reach the required temperature, they proceed to the next stage of production. Here, they undergo processes like rolling, forging, and machining to transform them into the final shape and size needed for the specific railway component. For example, in the production of railway rails, heated steel billets pass through a series of rolling mills, gradually shaping and elongating them into the desired rail profile. Similarly, for wheels and axles, billets are forged and machined to achieve the necessary dimensions and surface finish. The utilization of steel billets ensures that the resulting railway components possess strength, durability, and the ability to withstand the heavy loads and stresses associated with railway operations. The quality and characteristics of the steel billets greatly influence the performance and lifespan of the railway components. In summary, steel billets play a critical role in producing railway components by providing the raw material that is shaped, formed, and processed into the essential final products for the safe and efficient operation of the railway system.

- Q: How do steel billets contribute to the manufacturing of construction materials?

- Steel billets play a vital role in the manufacturing of construction materials. They serve as the raw material that is transformed into various steel products used in construction projects. Firstly, steel billets are the starting point for the production of different types of steel products such as bars, rods, beams, and sections. These products are essential components in the construction industry as they provide structural support and reinforcement. For example, steel bars are commonly used in the construction of reinforced concrete structures, providing strength and durability to the building. Furthermore, steel billets are also utilized in the manufacturing of pipes and tubes, which are crucial for plumbing, heating, ventilation, and air conditioning (HVAC) systems in buildings. These pipes and tubes ensure the efficient flow of water, gas, and air, contributing to the overall functionality and comfort of the structure. Moreover, steel billets are utilized in the production of steel sheets and plates, which are widely used in construction applications such as roofing, cladding, and flooring. Steel sheets and plates offer excellent strength, corrosion resistance, and aesthetic appeal. They are commonly used in high-rise buildings, warehouses, and industrial facilities. Additionally, steel billets are crucial in the production of prefabricated construction materials. Prefabrication involves the manufacturing of building components off-site, which are then transported and assembled on-site. Steel billets are used to create prefabricated steel frames, trusses, and panels, streamlining the construction process and reducing time and labor costs. In summary, steel billets are the foundation of the construction materials industry. They are transformed into various steel products that are essential for structural support, reinforcement, plumbing, HVAC systems, roofing, cladding, flooring, and prefabrication. The use of steel billets ensures the strength, durability, and functionality of construction materials, contributing significantly to the overall quality of construction projects.

- Q: How are steel billets used in the manufacturing of springs?

- Steel billets are used in the manufacturing of springs by being heated and then forged or rolled into the desired shape and size. These billets serve as the raw material for producing high-quality springs, providing the necessary strength and durability required for various applications.

- Q: What are the potential applications of steel billets in the automotive sector?

- Steel billets have a wide range of potential applications in the automotive sector. One of the key uses of steel billets is in the production of automotive parts and components. These billets can be further processed and shaped into various forms such as rods, bars, and sheets to manufacture critical components like engine parts, chassis, and suspension systems. The strength and durability of steel make it an ideal material for automotive applications. Steel billets can be transformed into high-strength steel alloys, which are known for their excellent mechanical properties, including high tensile strength, hardness, and impact resistance. These properties make steel billets suitable for use in structural components, such as the frame and body of vehicles, providing stability and enhancing passenger safety. Steel billets are also used in the production of engine parts, such as crankshafts, camshafts, and connecting rods. These components require high strength and resistance to wear and fatigue, which steel billets can provide. Additionally, steel billets can be used to manufacture gears, axles, and transmission components, which require excellent mechanical properties to withstand the demanding conditions of the automotive industry. Furthermore, steel billets find application in the manufacturing of suspension systems, including control arms, stabilizer bars, and springs. These components need to withstand heavy loads, vibrations, and impacts while ensuring optimal ride comfort and handling. Steel billets' high strength and toughness make them suitable for these critical suspension components. Moreover, steel billets are also utilized in the production of safety features in automobiles. For instance, they can be used to manufacture reinforced door beams, which enhance the structural integrity of the vehicle and provide protection in the event of a collision. Additionally, steel billets can be employed in the production of seat frames and seatbelt components, ensuring passenger safety and restraint systems. Overall, the potential applications of steel billets in the automotive sector are vast and crucial. Their strength, durability, and excellent mechanical properties make them indispensable for the production of various automotive components, ranging from engine parts to structural elements and safety features.

- Q: Billet market trend

- 3, Tangshan billet inventory declineIt is understood that in April, the Tangshan region began to decline in the stock of major steel warehouse, as of April 28th, Tangshan billet inventory at about 1 million 250 thousand tons, a drop of about half higher than the high point. But some vendors have revealed that some of the resources are being transferred from the warehouse to the traders. In fact, inventories are much larger than statistics, and the inventory of 1 million 250 thousand tons of steel is about 2.5 times that of the same period of last year.In addition, network analyst China industry insight believes the macroeconomic situation, the weakening of steel and steel industry more negative news of the credit crisis will be unfavorable to the billet market outlook. But considering the steel production has been at a loss, the billet has a certain resilience; and before the May Day holiday billet prices fell rapidly, it is possible to pull up the opportunity to play after the manufacturers in a certain way.

- Q: What are the different methods of steel billet testing?

- There are several different methods of steel billet testing that are commonly used in the industry. These methods aim to assess the quality and integrity of the steel billets before they are further processed or used in construction. Some of the different methods of steel billet testing include: 1. Visual Inspection: This is the most basic method of testing, where the surface of the steel billet is visually examined for any visible defects such as cracks, surface irregularities, or any other signs of damage. 2. Ultrasonic Testing: Ultrasonic waves are used to detect any internal defects or inconsistencies in the steel billet. A transducer is used to emit high-frequency sound waves into the billet, and the reflected waves are analyzed to identify any flaws or irregularities. 3. Magnetic Particle Inspection: This method is used to detect surface or near-surface defects in the steel billet. Magnetic particles are applied to the surface of the billet, and if there are any defects, the particles will be attracted and form visible indications that can be easily detected. 4. Eddy Current Testing: This non-destructive testing method involves using electromagnetic induction to detect any surface or near-surface defects in the steel billet. An alternating current is passed through a coil, creating a magnetic field. Any irregularities or defects in the billet will cause changes in the magnetic field, which can be detected and analyzed. 5. Chemical Analysis: This method involves analyzing the chemical composition of the steel billet to ensure it meets the required specifications. It typically involves techniques such as spectroscopy or wet chemistry methods to determine the levels of various elements present in the billet. 6. Tensile Testing: This method involves subjecting a small sample of the steel billet to tension until it breaks. The tensile strength and other mechanical properties can be determined through this test, providing valuable information about the overall strength and durability of the steel billet. 7. Hardness Testing: This method measures the hardness of the steel billet, which is an important property for determining its suitability for specific applications. Various hardness testing methods such as Rockwell, Brinell, or Vickers hardness tests can be used. Each of these testing methods has its own advantages and limitations, and the choice of method depends on the specific requirements and quality standards of the steel billet being tested.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 5#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords