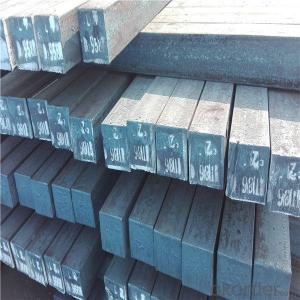

hot rolled steel billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Packaging & Delivery

| Packaging Detail: | in bundles |

| Delivery Detail: | according to the quantity |

Specifications

square steel billet

1.3SP, 5SP

2.terms of payment: L/C at sight

3.size: 120*120mm

4.length: 5.8~12m

square steel billet

Specifications

square steel billets

1)We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

M.S. Billets

CRS Billets

Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used fro rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

The following are the sizes of Billets available with Shyam Steel Industries Ltd.:

100 X 100

120x120

150 X 150

Physical Properties:

Description | As per IS 2830 | Shyam Billets |

| Bend (max.) | 5 mm per meter | >= 5 mm per meter |

| Carbon (max.) | 3mm per meter | >= 3 mm per meter |

| Length | 3 mt - 13 mt | 3 mt - 9 mt |

Chemical Properties:

Ladle Analysis: | ||

Designation | Carbon | Manganese |

| C15 | 0.12-0.18 | 0.30-0.60 |

| C18 | 0.15-0.21 | 0.30-0.60 |

| C20 | 0.17-0.23 | 0.30-0.60 |

| C15 MMn | 0.12-0.18 | 0.60-1.00 |

| C18 MMn | 0.15-0.21 | 0.60-1.00 |

| C20 MMn | 0.17-0.23 | 0.60-1.00 |

| C15 HMn | 0.12-0.18 | 1.00-1.50 |

| C18 HMn | 0.15-0.21 | 1.00-1.50 |

C20 HMn | 0.17-0.23 | 1.00-1.50 |

Billets of different designations are manufactured in three different grades namely A, B, C having sulphur, phosphorous content (on ladle analysis) and carbon equivalent as follows:

| Chemical Analysis: | |||

| Grade | Sulphur | Phosphorous | Carbon Equivalent (CE)1 |

| Max | Max | Max | |

| A | 0.05 | 0.05 | 0.42 |

| B | 0.045 | 0.045 | 0.41 |

| C | 0.04 | 0.04 | 0.39 |

- Q: Can steel billets be used in the automotive industry?

- The automotive industry makes use of steel billets, which are semi-finished steel products. These billets are typically further processed into different shapes and forms. In automotive manufacturing, steel billets are commonly utilized for producing various components like engine parts, transmission parts, chassis components, and suspension systems. This choice offers several benefits such as high strength, durability, and cost-effectiveness. Moreover, steel billets can be easily shaped, machined, and welded to meet specific design requirements and performance standards in the automotive sector. As a result, steel billets play a crucial role in automobile production, contributing significantly to the overall performance, safety, and reliability of vehicles.

- Q: What is the impact of impurities on the quality of steel billets?

- The quality of steel billets is greatly influenced by impurities. Steel billets, which serve as raw materials for various steel products, can be negatively affected by the presence of impurities. To begin with, the mechanical properties of steel billets can be weakened by impurities. For example, sulfur can cause sulfide inclusions, which reduce the strength and toughness of the steel. Similarly, phosphorus can lead to phosphide inclusions that negatively impact the ductility and impact resistance of the billets. These impurities can also promote the formation of cracks and other defects, further compromising the quality of the steel. Additionally, the machinability of steel billets can be adversely affected by impurities. Higher levels of impurities can increase the hardness and decrease the machinability of the steel, making it more challenging to shape into the desired end products. Consequently, this can lead to increased processing time and cost, as well as reduced productivity. Furthermore, the surface finish of steel billets can be impacted by impurities. Oxide inclusions, which are commonly formed due to impurities, can cause surface defects and roughness. This can negatively affect the appearance and aesthetics of the final steel products, making them less desirable in the market. Moreover, impurities can influence the corrosion resistance of steel billets. Some impurities, like chromium and nickel, can improve the corrosion resistance of steel. However, other impurities such as sulfur and phosphorus can promote corrosion, decreasing the lifespan and reliability of the steel products made from these billets. In conclusion, impurities have a significant impact on the quality of steel billets, resulting in weakened mechanical properties, reduced machinability, compromised surface finish, and decreased corrosion resistance. Therefore, it is crucial for steel manufacturers to carefully control and minimize the presence of impurities during the production process to ensure the production of high-quality steel billets.

- Q: Can steel billets be used in the production of appliances?

- Yes, steel billets can be used in the production of appliances. Steel billets, which are semi-finished products of steel, can be further processed and shaped into various components and parts that are used in appliances manufacturing. The high strength and durability of steel make it a suitable material for appliances, providing stability and reliability to the finished products.

- Q: Charcoal classification

- Hard charcoal. By hardwood such as Fagaceae Quercus, Castanopsis trees, secondary birch and etc..Broad-leaved charcoal. Charcoal made from a mixture of hard and soft hardwood.Pine charcoal. Carbon fired from pine or other needle wood. In addition to bamboo and bamboo charcoal burning with shells, stones (coconut shell, peach stone charcoal etc.) wood raw material firing. Charcoal collected from household stoves in the cell known as carbon. If the charcoal is crushed and mixed with proper adhesive, and then pressed, formed and roasted, the deposit is made. According to the burning process of silica and carbon black.

- Q: How do steel billets contribute to the circular economy?

- Steel billets contribute to the circular economy by enabling the recycling and reuse of steel. They serve as a raw material for various industries, including construction, automotive, and manufacturing, allowing for the production of new steel products from recycled steel. By using steel billets, the circular economy promotes the reduction of waste and the conservation of resources, as it minimizes the need for extracting and processing raw materials, thereby reducing energy consumption and environmental impact.

- Q: How are steel billets used in the manufacturing of food processing equipment?

- Steel billets are an essential component in the manufacturing of food processing equipment. These billets, which are semi-finished steel products, serve as the raw material for the fabrication of various components and parts required in the construction of food processing machinery. Firstly, steel billets are used to create the main structural frame of the equipment. The strong and durable nature of steel makes it ideal for providing the necessary strength and stability to support the entire machinery. The billets are cut and shaped into the desired dimensions to form the framework, ensuring that it can withstand the rigorous demands of industrial food processing. Moreover, steel billets are also used to manufacture specific components within the equipment. For instance, they are utilized to create cutting blades, grinding discs, and mixing paddles that are crucial in the food processing process. These components need to be robust and resistant to wear and corrosion, and steel billets offer the ideal material to meet these requirements. In addition, steel billets are often used to construct food processing equipment that requires high levels of hygiene and cleanliness. Stainless steel billets, in particular, are favored in such applications due to their inherent resistance to rust and corrosion. These billets are used to fabricate parts that come into direct contact with food, such as storage tanks, conveyors, and mixing chambers, ensuring that the food processing equipment is safe and hygienic. Furthermore, steel billets are employed in the manufacturing of heat exchangers and boilers used in food processing. These billets are designed to withstand high temperatures and pressure, making them suitable for applications that involve cooking, sterilization, or pasteurization of food products. In conclusion, steel billets play a crucial role in the manufacturing of food processing equipment. From providing structural support to fabricating specific components, they contribute to creating robust, efficient, and hygienic machinery that is essential for the food industry.

- Q: What are the main factors affecting the surface quality of steel billets?

- The surface quality of steel billets is influenced by several factors. Firstly, the cleanliness of the steel plays a crucial role. Contaminants such as oxides, scale, and inclusions can negatively impact the surface quality. These impurities can cause defects like pits, cracks, and roughness on the surface. Secondly, the temperature during the steelmaking process is an important factor. If the steel is overheated, it can lead to excessive scaling and oxidation, resulting in a poor surface finish. On the other hand, if the steel is not heated adequately, it may have a non-uniform surface and inconsistent mechanical properties. Additionally, the presence of residual stresses can affect the surface quality. Uneven cooling or improper heat treatment can cause residual stresses, leading to surface cracks, warping, or distortion. The type and effectiveness of the surface treatment or finishing processes also impact the surface quality of steel billets. Processes like grinding, polishing, or shot blasting can improve the surface finish by removing defects and creating a smoother surface. Moreover, the quality of the equipment and tools used in steel production plays a significant role. Worn-out or poorly maintained machinery can result in surface defects, inadequate surface preparation, or improper handling, affecting the final surface quality. Lastly, the composition and microstructure of the steel itself influence the surface quality. Variations in alloying elements, grain size, and phase distribution can affect the surface finish, hardness, and overall quality of the billets. In conclusion, the main factors affecting the surface quality of steel billets include cleanliness, temperature control, residual stresses, surface treatment processes, equipment quality, and the composition of the steel. Addressing these factors through proper steelmaking practices, surface treatments, and quality control measures is crucial for achieving high-quality steel billets with superior surface finish.

- Q: What are the different surface defects found in alloy steel billets?

- Some common surface defects found in alloy steel billets include cracks, laps, seams, scabs, and surface scale. These defects can occur during the manufacturing process or as a result of handling and transportation.

- Q: What is the typical fatigue strength of a steel billet?

- The typical fatigue strength of a steel billet can vary depending on several factors such as the specific composition of the steel, the manufacturing process, and any surface treatments applied. Generally, fatigue strength refers to the ability of a material to withstand repeated loading and unloading cycles without failure. Steel, being a strong and durable material, typically exhibits a high fatigue strength compared to other materials. However, the exact value of fatigue strength can vary significantly depending on the specific grade of steel and its intended application. In engineering and industry, fatigue strength is often represented by a stress-life (S-N) curve, which plots the stress level applied to the steel billet against the number of cycles to failure. The shape of the curve provides valuable information about the fatigue behavior of the steel. It is important to note that the fatigue strength of a steel billet is usually determined through rigorous testing procedures, such as fatigue testing machines that subject the material to cyclic loading until failure occurs. These tests help engineers and manufacturers establish the safe operating limits for different steel grades and applications. Therefore, without specific information about the steel grade, manufacturing process, and any additional factors, it is not possible to provide a precise value for the typical fatigue strength of a steel billet. However, it is generally understood that steel has good fatigue resistance and can withstand a significant number of cycles before failure, making it a reliable choice for many structural and mechanical applications.

- Q: How are steel billets used in the construction of bridges?

- Due to their exceptional strength and durability, steel billets play a crucial role in bridge construction. These cylindrical pieces of raw steel are heated and shaped into various structural components, such as beams, columns, and girders, which serve as the foundation of bridge structures. The initial step in utilizing steel billets for bridge construction involves heating them in a furnace to make them malleable. Once the desired temperature is reached, the billets are passed through a series of rollers to shape them into the required sections. This process, referred to as hot rolling, guarantees that the steel achieves the necessary strength and structural integrity. Following this, the shaped steel billets undergo further processing and fabrication to form different bridge components. For example, beams are created by cutting and welding steel billets together to form long, horizontal members that bear the weight of the bridge deck. These beams are designed to withstand heavy loads and provide stability to the entire structure. On the other hand, columns are vertical members that transfer the load from the bridge deck to the foundations. Steel billets are shaped and joined together to construct these load-bearing columns, ensuring they possess the required strength to endure compression forces. Girders also play a vital role in bridge construction, serving as horizontal supports that span across the width of the bridge. Steel billets are shaped into girders, which are then fabricated and connected to the bridge's piers or abutments. These girders provide the necessary strength to evenly distribute the weight of the bridge deck. Aside from their strength, steel billets offer several advantages in bridge construction. They possess a high resistance to corrosion, guaranteeing the durability and longevity of the bridge structure. Additionally, steel billets are highly versatile, allowing engineers to create various shapes and sizes, enabling the design of bridges that meet specific project requirements. Overall, steel billets are extensively utilized in bridge construction due to their strength, durability, and versatility. They form the foundation of bridge structures, providing the necessary support and stability to ensure the safe and efficient transportation of people and goods.

Send your message to us

hot rolled steel billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords