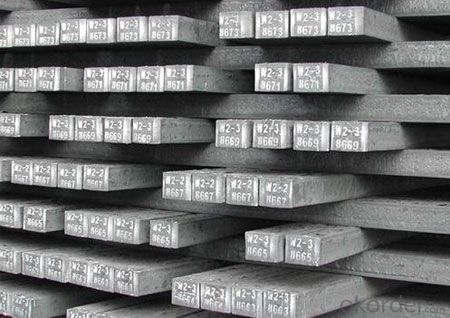

Steel Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continue casting round billets

Process: EAF+LF+VD+Continue CASTING,Delivery condtion:Hot forged+Normalzied+Rough Machined+Q/T.

Boiler Pipe Billets

Forging Steel Ingots

Stainless Steel Round Billets

Billets for Structural Seamless Pipe

Casing Steel Billets

Billets for Oil Well Casing Pipe

Stainless Steel Square Billets

Forging Square Steel Billets

Carbon Steel Square Billets

Stainless Steel Round Billets

Forging Round Billets

Line Pipe Steel Billets

Forging Ingot | |

| Range | Material |

| 5t-150t | Carbon Steel Ingot、Alloy Steel Ingot、Bearing Steel、Wind Power Steel、Nuclear Power Steel、Steel Mould Or Special Material |

Heavy Casting Or Forging Steel Billets | |

Casing Steel Billets: Min QTY 200 Ton、Forging Steel Billets: Min QTY 60Ton | Cooperative development according to customer requirements. |

The Continuous Casting Round Billet | ||

Name | Material | Size |

Billets for Structural Seamless Pipe | 10#、20#、35#、45#、345B、27SiMn、20Mn2 | φ180mm-φ600mm |

Billets for Low&Medium Pressure Boiler Pipe | 20# | φ180mm-φ600mm |

Billets for high pressure boiler pipe | 20G、SA-192、SA-106B、SA-106C、SA-210A1、SA-210B、SA-210C、37Mn、34Mn2V、30CrMo、35CrMo、34CrMo4、SA335-P2、SA335-P11、SA335-P12、16MnG、25MnG、15MoG、16Mo3、13CrMo4-4、10CrMo9-10、15CrMoG、12Cr1MoVG | Φ180mm-Φ600mm |

Billets for Oil Well Casing Pipe | 37Mn5、34Mn6、25Mn2V、30Mn2V-36Mn2V、26CrMo4、32CrMo4、29MnCr6、29CrMo4-4、40CrMo4 | Φ180mm-Φ600mm |

Billets for Line Pipe | L245(B)、L245NB、X42(L290)、X46(L320)、X52(L360)、L320NB、L360NB、L245NCS、L290NCS、L360NCS | Φ180mm-Φ600mm |

Forging Round Steel Billets & Square Billets | 45#、50Mn、40Cr、GCr15、GCr15SiMn、Q345E、35CrMo、42CrMo、42CrMo4 | Round Steel Billets:φ180mm-φ600mm |

Stainless Steel Round Billets &Square Billets | 1Cr13、2Cr13、3Cr13、4Cr13、1Cr18Ni9Ti | Round Steel Billets:φ180mm-φ600mm |

- Q: How are steel billets used in the production of automotive components?

- Steel billets are a crucial raw material used in the production of automotive components. In the manufacturing process, steel billets are heated and then forged or rolled into various shapes and sizes to create the desired automotive parts. These billets serve as a starting point for the production of components such as engine blocks, crankshafts, connecting rods, axles, and suspension parts. The high strength and durability of steel make it an ideal material for these critical components, ensuring the safety and performance of automobiles. Once heated, the steel billets are subjected to various shaping processes, such as hot forging or hot rolling. Hot forging involves applying pressure to the heated billet using a die to create the desired shape. This process not only gives the component its final shape but also improves its mechanical properties by aligning the steel's grain structure. Hot rolling, on the other hand, involves passing the heated billet through a series of rolling mills to gradually reduce its thickness and shape it into a specific profile. This process is commonly used for producing long automotive components like axles or suspension parts. After the shaping process, the automotive components undergo additional manufacturing steps like heat treatment, machining, and surface finishing to enhance their strength, precision, and aesthetic appeal. Steel billets offer several advantages in automotive component production. Their excellent mechanical properties, including high strength, toughness, and wear resistance, make them ideal for withstanding the demanding conditions and loads experienced by automotive parts. Additionally, steel's ability to be easily shaped and formed allows manufacturers to create complex and intricate designs, ensuring optimal functionality and performance. In conclusion, steel billets play a vital role in the production of automotive components by providing the raw material that is shaped and formed into various critical parts. The strength, durability, and versatility of steel make it an essential material for ensuring the safety, reliability, and performance of automobiles.

- Q: What is the typical tensile strength of a steel billet?

- The typical tensile strength of a steel billet can vary depending on factors such as the specific grade of steel and the manufacturing process. However, on average, steel billets typically have a tensile strength ranging from 400 to 600 megapascals (MPa).

- Q: How are steel billets used in the production of seamless pipes?

- Steel billets are heated and then pierced to form a hollow tube, which is then elongated and rolled into a seamless pipe. The billets serve as the starting material for the production of seamless pipes, providing the necessary shape and strength required for the manufacturing process.

- Q: What is the role of steel billets in the manufacturing of structural steel bridges?

- Structural steel bridges heavily rely on steel billets, which are essential semi-finished products utilized as the raw material for manufacturing various steel products, including these bridges. The initial step involves heating the steel billets and passing them through a series of rolling mills to shape them accordingly. This rolling process ensures that the billets are converted into elongated, slender sections suitable for bridge construction. Once the steel billets have been rolled into the desired forms, they undergo further processing and fabrication to create the necessary components for structural steel bridges. These components encompass beams, columns, girders, and other vital elements that contribute to the bridge's strength, stability, and load-bearing capabilities. The utilization of steel billets in the production of structural steel bridges provides numerous advantages. Firstly, steel possesses an exceptional strength-to-weight ratio, rendering it an ideal material for constructing bridges capable of withstanding heavy loads while remaining relatively lightweight. Moreover, steel's versatility allows for the creation of intricate bridge designs that can accommodate diverse architectural and engineering requirements. Furthermore, steel billets exhibit high durability and resistance to environmental factors like corrosion, which is crucial for ensuring the long-term integrity and safety of the bridge structure. This durability ultimately contributes to the bridge's extended lifespan, leading to reduced maintenance and replacement costs over time. In conclusion, steel billets serve as the fundamental building blocks for the manufacturing of structural steel bridges. Through the rolling and fabrication processes, these billets are transformed into various components that collectively provide strength, stability, and durability to the bridge. The utilization of steel billets enables the construction of bridges capable of withstanding heavy loads, maintaining a lightweight nature, and enduring environmental factors, thereby ensuring the bridge's long-term integrity and safety.

- Q: What are the different methods of steel billet casting?

- In the industry, various methods are commonly used for steel billet casting. These methods encompass continuous casting, ingot casting, and direct casting. Continuous casting stands as the most widely employed method for steel billet casting. In this process, molten steel is poured into a water-cooled mold, typically made of copper. As the steel cools and solidifies, a seamless billet is formed, which is subsequently cut into desired lengths. Continuous casting allows for high production rates and precise control over billet dimensions and quality. Ingot casting represents an alternative method for steel billet casting. It involves pouring molten steel into individual molds to create ingots. These ingots are then allowed to solidify before being reheated and hot rolled into billets. Ingot casting is often utilized for small-scale production or for specialty steel alloys that require specific compositions. Direct casting, also known as strand casting, emerges as a newer method for steel billet casting, eliminating the need for solidification and reheating processes. In this method, molten steel is directly poured into billets through a series of water-cooled copper molds. The billets are subsequently cooled and cut to the desired lengths. Direct casting offers advantages such as reduced energy consumption and improved yield by eliminating the intermediate steps of ingot casting. Ultimately, the selection of the steel billet casting method relies on factors like production volume, desired quality, and specific requirements of the steel alloy being produced. Each method possesses its own advantages and limitations, and choosing the appropriate method is vital for ensuring efficient and cost-effective steel billet production.

- Q: How do steel billets contribute to the defense industry?

- Steel billets play a crucial role in the defense industry by providing the necessary raw material for manufacturing various defense equipment and vehicles. These billets are essentially semi-finished steel products that are used as a starting point for further processing and shaping into specific components. One of the primary applications of steel billets in the defense industry is in the production of armored vehicles. These vehicles require a high level of protection to withstand potential threats such as ballistic attacks or explosive devices. Steel billets are used to manufacture the armor plates and panels that provide the necessary strength and resilience to these vehicles. Additionally, steel billets are utilized in the production of various weapon systems, including firearms, artillery guns, and missiles. The strength and durability of steel make it an ideal material for constructing the barrels, chambers, and other critical components of these weapons. The ability of steel to withstand high temperatures and pressures is crucial for ensuring the reliable and efficient performance of these defense systems. Furthermore, steel billets are also used in the manufacturing of naval vessels, submarines, and aircraft carriers. These military ships and submarines require steel components that can withstand the harsh marine environment, including corrosion, impact, and extreme temperatures. Steel billets are used to produce these components, ensuring the structural integrity and longevity of these vessels. In summary, steel billets are indispensable to the defense industry as they provide the essential raw material for manufacturing a wide range of defense equipment. Their strength, durability, and versatility make them ideal for producing armored vehicles, weapon systems, naval vessels, and other defense-related components. By contributing to the production of these crucial assets, steel billets play a vital role in strengthening national defense capabilities.

- Q: What are the main factors affecting the dimensional stability of steel billets?

- The main factors affecting the dimensional stability of steel billets include temperature variation, cooling rate, composition of alloying elements, and the presence of residual stresses.

- Q: What are the different types of defects that can occur during steel billet production?

- During steel billet production, various types of defects can occur that may affect the quality and performance of the final product. Some of the common defects observed in steel billets are: 1. Surface Defects: These defects occur on the surface of the billet and can include scales, cracks, pits, scars, and slivers. Surface defects can be caused by improper handling, poor lubrication, inadequate heating, or contamination during the manufacturing process. 2. Internal Defects: Internal defects occur within the billet and can be more challenging to detect. Examples of internal defects include voids, porosity, inclusions, and segregation. Internal defects can arise due to improper alloying, inadequate mixing, or improper casting and solidification processes. 3. Shape Defects: Shape defects refer to any deviation from the desired dimensions or geometry of the billet. These defects can include bending, bowing, twisting, or excessive tapering. Shape defects can be caused by improper rolling or cooling processes, inadequate maintenance of rolling equipment, or poor billet handling. 4. Chemical Composition Defects: Steel billets must meet specific chemical composition requirements to ensure desired material properties. Defects in chemical composition can occur due to improper mixing of raw materials, incorrect temperature control, or contamination during the manufacturing process. These defects can negatively impact the mechanical properties, such as strength, ductility, or corrosion resistance, of the final product. 5. Incomplete Solidification: Incomplete solidification can lead to defects like centerline segregation or shrinkage cavities. These defects occur when the cooling rate is too fast or uneven, preventing the complete solidification of the billet. Incomplete solidification can weaken the billet structure, affecting its overall integrity and performance. 6. Dimensional Defects: Dimensional defects refer to deviations in the size, length, width, or thickness of the billet. These defects can occur due to inaccurate measurement or control during the manufacturing process. Dimensional defects can impact the fitment or compatibility of the billet in subsequent processes or applications. It is crucial for steel billet manufacturers to implement stringent quality control measures to minimize the occurrence of these defects. Regular inspections, process optimization, and adherence to industry standards and best practices can help mitigate defects and ensure the production of high-quality steel billets.

- Q: What are the different types of steel billet surface defects?

- There are several different types of steel billet surface defects that can occur during the manufacturing process. These defects can affect the quality and performance of the steel, and it is important to identify and address them to ensure the integrity of the final product. 1. Scale: Scale is a common defect that occurs as a result of oxidation during the heating and rolling process. It appears as a thin layer of iron oxide on the surface of the billet and can be easily removed through descaling processes. 2. Cracks: Cracks are another common defect that can occur on the surface of steel billets. They can be caused by several factors such as uneven cooling, excessive stress, or improper handling. Cracks can lead to weakened structural integrity and should be repaired or the affected billets discarded. 3. Pitting: Pitting is a defect characterized by small, shallow depressions or pits on the surface of the billet. It can be caused by a variety of factors including impurities in the steel, improper cooling, or corrosion. Pitting can lead to reduced strength and increased susceptibility to corrosion. 4. Lamination: Lamination defects occur when there are layers or separation within the billet caused by poor bonding during the manufacturing process. This defect can compromise the mechanical properties of the steel and may result in failure under stress. 5. Inclusions: Inclusions are non-metallic substances that become trapped within the billet during the manufacturing process. They can include slag, oxides, or other impurities. Inclusions can weaken the steel and reduce its ductility, making it more prone to cracking or breaking. 6. Scratches: Scratches are superficial defects that can occur during handling or transportation of the billets. While they may not greatly affect the overall structural integrity of the steel, they can lead to localized stress concentrations and potential failure in certain applications. 7. Decarburization: Decarburization is a defect that occurs when the surface of the billet loses its carbon content during the heating process. This can lead to reduced hardness and strength in the affected area, affecting the performance of the steel. It is important for manufacturers and inspectors to be aware of these different types of steel billet surface defects to ensure the production of high-quality steel products. Regular inspections, quality control measures, and appropriate corrective actions can help minimize and address these defects to ensure the desired performance and longevity of the steel.

- Q: How are steel billets used in the production of power generation equipment?

- Steel billets are used in the production of power generation equipment as they serve as the raw material for various components such as turbine blades, rotors, shafts, and casings. These billets are heated, forged, and machined to create the necessary shapes and sizes required for the efficient and reliable functioning of power generation equipment. The high strength and durability of steel make it an ideal choice for withstanding the extreme conditions and stresses involved in power generation processes.

Send your message to us

Steel Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords