hot rolled billet steel producers in very good price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STEEL BILLET

1.Brief description

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

2.Features

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

3.Processing

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

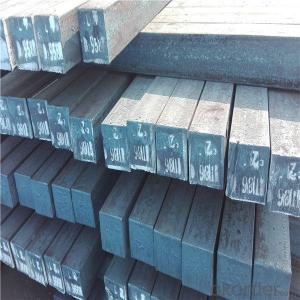

4.Pictures

5.Usage

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

6.Detailed specification

Hot rolled billet steel

Size: 50x50mm-180x180mm

Steel Grade: 3SP, 5SP,Q195,Q235,Q255,Q275 Length:3m-12m

MOQ: 1000MT/size

Payment term: TT or LC

Packing: in bulk , bundle

Shipment: by container , bulk vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: 15-30 days after the deposit

Loading port:Tianjin, or other port China

Origin : China

Inspection:Third party inspection before loading.

- Q: For example, screw plate (PU plate and manganese plate), carbon steel Primeton is what person rolling out?.

- Primeton Pu board generally refers to A3; carbon steel refers to the high quality carbon steel, such as No. 45 steel, 35 steel and so on;

- Q: What are the factors that affect the price of steel billets?

- The price of steel billets can be affected by several factors. 1. Raw material costs have a significant impact on the price of steel billets. Fluctuations in the cost of iron ore, coal, and other raw materials used in steel production directly influence the price of steel billets. 2. The supply and demand dynamics of steel billets play a crucial role in determining their price. An increase in demand for steel products, such as construction materials or automotive parts, can drive up the price of steel billets. Conversely, an oversupply can lead to a decrease in price. 3. Energy costs required for steel production can impact the price of steel billets. Fluctuations in energy prices affect the overall production cost and, subsequently, the price of steel billets. 4. Currency exchange rates can have a significant impact on the price of steel billets. If the currency of the country producing steel billets weakens against other currencies, it can make the product more affordable and potentially increase demand. 5. Government regulations, trade policies, and tariffs imposed on steel billets can influence their price. Tariffs can increase the cost of imported steel billets, making domestically produced steel billets relatively more competitive and potentially leading to higher prices. 6. The overall state of the economy, both locally and globally, can impact the price of steel billets. During periods of economic growth, there is typically higher demand for steel products, which can drive up the price. Conversely, during economic downturns, demand may decrease, resulting in lower prices. 7. Technological advancements in steel production can impact the price of steel billets. Innovations that increase efficiency and reduce production costs can potentially lead to lower prices, while new technologies that improve the quality or properties of steel billets may command a higher price. It is important to note that these factors are interconnected and can influence each other. Therefore, understanding the complex relationship between these factors is essential in analyzing and predicting the price of steel billets.

- Q: How are steel billets used in the production of oil and gas pipelines?

- Steel billets are used in the production of oil and gas pipelines as they serve as the raw material for manufacturing pipeline sections. These billets are heated, shaped, and welded to form seamless or welded pipeline pipes. The high strength and durability of steel make it an ideal material for pipelines, providing a reliable and safe means of transporting oil and gas over long distances.

- Q: What is the role of steel billets in the manufacturing of railway signaling systems?

- Steel billets play a crucial role in the manufacturing of railway signaling systems. These billets serve as the primary raw material for the production of various components that are essential for the functioning of these systems. Railway signaling systems are responsible for ensuring the safe and efficient movement of trains on the tracks. They comprise a complex network of electrical and mechanical devices that control the traffic flow, provide information to train operators, and maintain a safe distance between trains. To manufacture these systems, steel billets are utilized in several ways. Firstly, steel billets are used to produce the structural components of railway signaling systems. These components include signal poles, posts, and brackets that support the signaling devices such as lights, signals, and indicators. Steel is chosen for these structural elements due to its high strength, durability, and resistance to environmental factors such as wind, rain, and temperature fluctuations. Secondly, steel billets are employed in the production of various electrical components used in railway signaling systems. These components include wiring conduits, junction boxes, and mounting plates that house and protect the electrical connections and circuitry. Steel's electrical conductivity properties make it an ideal material for these applications. Additionally, steel billets are also utilized in the manufacturing of mechanical components within railway signaling systems. These components include gears, levers, and linkages that facilitate the movement and operation of the signaling devices. Steel's mechanical properties, such as its hardness and ability to withstand high loads, ensure the reliability and longevity of these mechanisms. In summary, steel billets are essential in the manufacturing of railway signaling systems as they provide the necessary raw material for the production of structural, electrical, and mechanical components. Their strength, durability, electrical conductivity, and mechanical properties make them well-suited for the demanding requirements of these systems, ultimately contributing to the safe and efficient operation of railways.

- Q: What are the different production methods for steel billets?

- There are several different production methods for steel billets, including continuous casting, ingot casting, and direct hot rolling. Continuous casting involves pouring molten steel into a water-cooled mold to form a continuous strand, which is then cut into desired lengths. Ingot casting involves pouring molten steel into individual molds to form solid blocks, which are later reheated and rolled into billets. Direct hot rolling involves passing a large steel ingot through a series of rolling mills to reduce its size and shape it into a billet.

- Q: Are steel billets used in the production of sporting goods?

- Yes, steel billets are commonly used in the production of sporting goods. They are often utilized to create various components such as the shafts of golf clubs or the frames of bicycles. Steel billets provide durability and strength to these sporting goods, making them suitable for intense physical activity.

- Q: How are steel billets used in the production of wire rods?

- Wire rods are produced from steel billets, which are a vital raw material. These cylindrical billets serve as the starting point for the wire rod manufacturing process. To achieve the desired temperature for hot rolling, the steel billets are heated in a furnace. Once heated, the billets are sent through a series of rolling mills, where they undergo hot rolling. During this process, the billets are passed through rollers that gradually decrease their diameter and increase their length. This transformation results in the creation of long, thin, and continuous wire rods. Hot rolling causes the steel billets to undergo plastic deformation, wherein their shape changes due to the application of heat and pressure. This alteration aligns the internal grain structure of the steel, resulting in improved mechanical properties like strength, ductility, and toughness. Upon completion of the hot rolling process, the wire rods are typically coiled and cooled. These rods may then undergo additional treatments such as pickling, surface coating, or heat treatment to enhance their quality and suitability for specific applications. Finally, the wire rods are ready for use in various industries, such as automotive, construction, and manufacturing. They are utilized in the production of a wide range of products including wires, cables, nails, screws, and reinforcement bars. In conclusion, wire rods are derived from steel billets through the hot rolling process. This involves heating the billets, passing them through rolling mills to alter their dimensions, and subsequently treating and cooling them. The resulting wire rods play a crucial role in the production of diverse products, thus making them an indispensable component.

- Q: How are steel billets used in the manufacturing of industrial valves?

- Steel billets are an integral component in the manufacturing of industrial valves. Valves are crucial devices used to control the flow of fluids or gases in various industrial processes. Steel billets, which are semi-finished metal products, play a significant role in the production of these valves. The manufacturing process of industrial valves typically involves several steps, including forging, machining, and assembly. Steel billets are primarily used in the forging stage of valve production. Forging is the process of shaping metal by applying localized compressive forces using dies or hammers. Steel billets are heated to a specific temperature and then subjected to intense pressure, which deforms them into the desired shape. The use of steel billets in forging valves offers several advantages. Firstly, steel is known for its exceptional strength and durability, making it an ideal material choice for valves that are exposed to high-pressure environments. Steel billets provide the necessary raw material to create robust and reliable valve components. Additionally, steel billets can be easily shaped and molded during the forging process. This allows manufacturers to create complex valve designs with precision and accuracy. The versatility of steel billets enables the production of valves in various sizes, shapes, and configurations to meet specific industrial requirements. Furthermore, steel billets can be heat-treated after forging to enhance their mechanical properties. Heat treatment processes like quenching and tempering can significantly improve the hardness, strength, and wear resistance of the valve components. This ensures that the valves can withstand harsh operating conditions and deliver optimal performance over an extended period. In conclusion, steel billets are essential in the manufacturing of industrial valves. They provide the raw material required for forging valve components, offering strength, durability, and versatility. The use of steel billets enables the production of high-quality valves that can effectively control the flow of fluids or gases in industrial processes.

- Q: What are the international standards or certifications for steel billets?

- The international standards or certifications for steel billets include ASTM A615/A615M-20, ASTM A706/A706M-16, BS 4449:2005+A3:2016, and EN 10025-2:2004. These standards provide specifications for the chemical composition, mechanical properties, and dimensions of steel billets, ensuring their quality and suitability for various applications in the construction industry.

- Q: How are steel billets used in the manufacturing of electrical transmission equipment?

- Steel billets are often used as raw material in the manufacturing of electrical transmission equipment. They are typically forged or machined to create various components such as brackets, supports, and housings. These billets provide the necessary strength, durability, and dimensional stability required for the equipment to withstand high electrical loads and harsh operating conditions.

Send your message to us

hot rolled billet steel producers in very good price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords