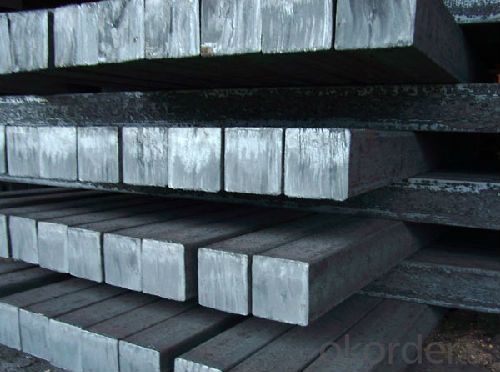

Hot Rolled Steel Billet Make in China for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Billet Make in China for Sale with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Billet Make in China for Sale are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Billet Make in China for Sale are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Packaging & Delivery:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What is the role of steel billets in the construction of stadiums and arenas?

- Steel billets play a crucial role in the construction of stadiums and arenas as they are the primary raw material used to manufacture structural steel components. These billets are heated and shaped into various forms, such as beams, columns, and trusses, which provide the necessary support and framework for the overall structure. The high strength and durability of steel make it an ideal material to withstand the heavy loads and forces experienced in these large-scale facilities. Additionally, steel billets can be easily fabricated and assembled on-site, ensuring efficient construction and enabling the creation of complex designs and architectural features.

- Q: What are the dimensions of a typical steel billet?

- The dimensions of a typical steel billet can vary depending on its intended use and the specific manufacturing process. However, generally speaking, steel billets usually have a rectangular shape with widths ranging from 100mm to 300mm, heights ranging from 100mm to 400mm, and lengths ranging from 6m to 12m. These dimensions allow for easy handling and transportation, as well as flexibility in shaping and forming the steel billet into various end products like bars, rods, or sheets. It's worth noting that these dimensions are not set in stone and can be tailored to meet the specific requirements of the production process or the customer's preferences.

- Q: Can steel billets be used in the production of appliances?

- Appliances can indeed utilize steel billets for their production. These semi-finished products are typically employed for subsequent processing into diverse forms and dimensions. In the context of appliances, steel billets can serve as the primary material for fabricating elements like frames, panels, and other structural components. Steel possesses remarkable versatility and durability, providing robustness, stability, and corrosion resistance, thereby rendering it appropriate for appliances requiring sturdy construction. Moreover, steel can be effortlessly molded and shaped to fulfill the distinct design requisites of various appliances, making it the preferred choice in the manufacturing procedure.

- Q: What are the different surface treatments for improved dimensional accuracy in steel billets?

- There are several surface treatments that can be employed to enhance dimensional accuracy in steel billets. These treatments aim to reduce surface imperfections, improve surface finish, and minimize dimensional variations. Some common surface treatments for improved dimensional accuracy in steel billets include: 1. Shot blasting: This process involves propelling abrasive particles at high velocity onto the surface of the billet. Shot blasting removes any dirt, scale, or surface contaminants, resulting in a smoother and cleaner surface. This treatment helps to eliminate any potential dimensional variations caused by surface irregularities. 2. Peeling: Peeling is a machining process in which a thin layer of material is removed from the surface of the billet using a cutting tool. This treatment helps to eliminate surface defects and imperfections, resulting in improved dimensional accuracy. Peeling can also enhance the surface finish of the billet. 3. Grinding: Grinding is a process in which an abrasive wheel or belt is used to remove material from the surface of the billet. This treatment helps to remove any surface irregularities, such as high spots or scratches, resulting in improved dimensional accuracy. Grinding can also provide a smoother and more uniform surface finish. 4. Turning: Turning is a machining process in which a cutting tool is used to remove material from the surface of the billet. This treatment helps to achieve precise dimensions and surface finish. Turning can also be used to improve concentricity and straightness of the billet. 5. Polishing: Polishing involves using abrasive materials or compounds to create a smooth and reflective surface on the billet. This treatment helps to remove any surface imperfections, such as scratches or blemishes, resulting in improved dimensional accuracy and surface finish. It is important to note that the choice of surface treatment may vary depending on the specific requirements and desired outcomes. Manufacturers often employ a combination of these treatments to achieve optimal dimensional accuracy in steel billets.

- Q: What are the different surface treatments applied to stainless steel billets?

- There are several different surface treatments that can be applied to stainless steel billets, depending on the desired outcome and application. Some common treatments include passivation, pickling, electropolishing, and blasting. Passivation helps to improve corrosion resistance by removing any free iron from the surface. Pickling involves the use of acids to remove impurities and oxide layers from the surface. Electropolishing is an electrochemical process that provides a smooth and shiny finish. Blasting, on the other hand, involves using abrasive particles to remove surface contaminants and create a textured finish. These treatments can enhance the appearance, cleanliness, and durability of stainless steel billets for various industrial applications.

- Q: What is the shelf life of a steel billet?

- The durability of a steel billet can vary based on various factors. In order to prevent corrosion and uphold their quality, steel billets are typically stored in controlled environments. With proper storage, steel billets can remain usable for several years. However, it is essential to acknowledge that the shelf life can be influenced by factors such as humidity levels, exposure to moisture or chemicals, and the specific type of steel employed. Consequently, it is crucial to adhere to the storage guidelines provided by manufacturers to guarantee an extended shelf life for steel billets. Regular inspections and maintenance can also aid in identifying any potential issues that may impact the durability of the billets.

- Q: Can steel billets be used in the production of jewelry?

- No, steel billets cannot be used in the production of jewelry. Jewelry is typically made from precious metals such as gold, silver, or platinum, which offer a higher level of aesthetic appeal and value. Steel, being an alloy primarily used in construction and manufacturing industries, lacks the desired characteristics and appearance required for jewelry production.

- Q: What are the main factors affecting the machinability of steel billets?

- The machinability of steel billets, which refers to the ease with which they can be cut and shaped by machining processes, is influenced by several key factors. These factors include the composition of the steel, its microstructure, the presence of impurities or inclusions, and the mechanical properties of the material. The composition of the steel plays a crucial role in determining its machinability. Elements such as carbon, manganese, sulfur, and phosphorus can significantly affect the cutting performance. For instance, higher carbon content can increase hardness, making the steel more difficult to machine. On the other hand, manganese can improve machinability by enhancing the formation of a favorable microstructure. The microstructure of the steel, which is influenced by factors such as heat treatment and alloying elements, also affects machinability. Fine-grained steels with a homogeneous microstructure are generally easier to machine than coarse-grained ones. Additionally, the presence of alloying elements like chromium or molybdenum can improve machinability by enhancing the material's hardness and wear resistance. Impurities or inclusions in the steel, such as non-metallic particles or oxides, can have a detrimental effect on machinability. These impurities can cause tool wear, surface defects, and poor chip formation during machining. Therefore, the level of impurities in the steel should be minimized through careful production and refining processes. Furthermore, the mechanical properties of the steel, including its hardness, strength, and ductility, influence machinability. High-strength steels are typically more challenging to machine due to their increased hardness, which requires more cutting force. Ductility is also crucial as it affects the ability of the steel to form chips during machining. A balance between hardness and ductility is desirable for optimal machinability. In conclusion, the machinability of steel billets is determined by various factors, including composition, microstructure, impurities, and mechanical properties. Understanding and controlling these factors is essential for ensuring efficient and effective machining processes.

- Q: What are the main factors affecting the hardenability of stainless steel billets?

- The hardenability of stainless steel billets, or the ability of the material to be hardened through heat treatment, is influenced by several factors. 1. Alloy composition: The composition of stainless steel, particularly the content of elements such as carbon, chromium, nickel, and molybdenum, plays a significant role in its hardenability. Higher carbon content generally improves hardenability, while alloying elements like chromium and nickel enhance the corrosion resistance of stainless steel but may reduce its hardenability. 2. Grain size: The grain size of stainless steel billets affects the rate and depth of hardening. Finer grain structures tend to have better hardenability compared to coarser grain structures. This is because smaller grains allow for more uniform distribution of carbon and alloying elements, resulting in improved hardening response. 3. Heat treatment conditions: The specific heat treatment process used, including heating and cooling rates, soaking time, and quenching media, can significantly impact the hardenability of stainless steel billets. Proper control of these parameters is crucial to achieving the desired hardness and mechanical properties. 4. Cooling rate: The cooling rate during the quenching process is a critical factor in determining the hardenability of stainless steel. Rapid quenching, such as water or oil quenching, promotes martensitic transformation and greater hardness. Slower cooling rates, such as air cooling, result in a softer and less hardened structure. 5. Cross-sectional thickness: The thickness of the stainless steel billets also affects their hardenability. Thicker sections tend to have lower hardenability due to slower heat transfer rates during the quenching process. Thinner sections, on the other hand, can achieve higher hardness levels due to faster cooling rates. 6. Prior microstructure: The initial microstructure of the stainless steel billets, such as whether it is in the annealed or cold-worked condition, can influence hardenability. Cold work can introduce dislocations and grain boundaries, which may hinder the diffusion of carbon and alloying elements during heat treatment, resulting in reduced hardenability. Considering these factors, manufacturers and engineers must carefully select stainless steel grades and tailor the heat treatment process to achieve the desired level of hardenability and mechanical properties in stainless steel billets.

- Q: What are the different types of heat treatment processes used for steel billets?

- There are several different types of heat treatment processes used for steel billets. Some commonly used methods include annealing, normalizing, quenching and tempering, and case hardening. Each process has its own purpose and is used to achieve specific properties in the steel billets.

Send your message to us

Hot Rolled Steel Billet Make in China for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords