Single Stage Double Suction Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Stage Double Suction Centrifugal Water Pump for Irrigation

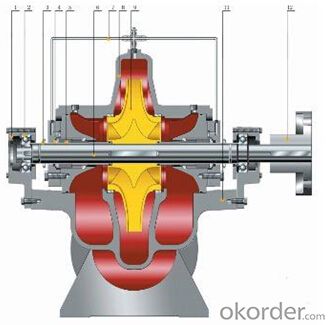

1.Structure of Single Stage Double Suction Split Casing Water Pump Description

The Single Stage Double Suction Water Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of the Single Stage Double Suction Water Pump

• Compact structure

• Attractive design

• High efficiency, steady performance

• big capacity, medium pressure

• High concentricity of components

3. Single Stage Double Suction Water Pump Images

4. Single Stage Double Suction Water Pump Specification

Specification Parameter of Single Stage Double Suction Split Casing Centrifugal Pump

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

5.FAQ

①What is the applications?

Besides irrigation and drainage pumping Station, the Single Stage Double Suction Split Casing Centrifugal Pump also can be used for Circulation water for air-condition, water supply for industry and building, and other waterworks.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q: how to remove water pump on 95 honda accord

- If you have an overheat problem the water pump IS NOT your problem. Save money and go to a RADIATOR SHOP and get an answer to your problem. Guessing is very expensive.

- Q: My water pump is losing pressure slowly even though no water is being used. Your help is appreciated. Thank you.

- I vote for the check valve in the well drop pipe. The valve and seat are both brass - no rubber seal - so it's bound to always leak somewhat. If the leak has increased recently, it's due to wear beginning to show or a bit of sand caught in it. A little extra on the electric bill is a lot less than the cost of pulling the well to replace the $20.00 valve. Another possibility:Your pressure tank air cushion may have lost air and become partially waterlogged. This will increase the pump operation. It won't run as long but it will run more often. The system pressure will drop faster than normal. Perhaps this is what you perceive as a leak. Ask your well man how to check the air pressure in your particular tank.

- Q: ive just replaced my water pump as i know it wasnt in good shape and was a big cause of my problems. but the new water pump also seems to make a noise once in a while like its dry and there isnt anywater or its having a hard time. the head is good and has an extra thick headgasket on it. my guess is i have a clogged radiator and it would sound reasonable as i have used head gasked sealant in the radiator and it has prob clogged parts of it. the other symptom is afater about 4 hrs of continuous driving it starts to over heat if im doing 70 bor more but if i drop back down to 65 it seems to stable out or in many cases go down all together. anyone else had thes symptoms. and will a water pump make noise if there isnt anywater to pump.

- what is the 22r fitted in as most run a thermo fan assy which is fitted to the front of the water pump if you have this then most likely the thermo is either just about to seize or it's still turn's then its in freewheel mode the best way to check is when the motor is cold check and se if you have a thermo fan fitted if so out one blade at 12 oclock and spin with one hand if the blade goes down past 3 oclock then you will need to open the coupling this is a simple job you will see 8 phillips head screws remove all and crack open the coupling but before this is done go to your local toyota dealer and purchase 1x 08816 10001 silicone empty this into the coupling and close this will fix your problem

- Q: Do I need to change the water pump if I replace the timing belt ? and does the water pump connect with the timing belt ? if the water pump goes out will it bend the rods ?

- There are always two reasons for which mechanic or the car owners should insist to change the water pump whenever, is time to change the timing belt -If your water pump is driven by the same timing belt; you should have to replace it ; or else you may pay more money for real serious damage in the future if it seizes due to high mileage on it or any fatigue of it,s own. -But if the water pump is driven with a separate belt . You should put that consideration in account for the reason to save money at this point, and furthermore prevent any Sudan over heating condition at any given time. The best way to know if your water pump whether driven by the timing or not ! You simply need to find out what type and size engine you have . Then you go to any auto part and ask them to show you the new pump. Try to show them some sign that you are going to buy the pump in order for them to show you the right pump. If that pump comes with a sprocket pulley. definitely is driven by the timing belt. If in fact your water pump is driven by the timing belt- Yes! you should anticipate to prepare a large amount of money to take care of that big damage within that engine( If that engine is interference engine )

- Q: Not sure of the year model but think it is a 1991 to 1995 Jayco 2500FS bumper pull trailer. I bought it to put on a deer lease. One of the previous owners had taken out the water tank which I plan on replacing. I can't find the water pump to see if I need to replace it as well. Also, if you know about how the pump knows when to kick on i.e. pressure switch, push button or what. I know I could take it to have repairs done but enjoy the diy thing. I am in the process of finding out the exact year model as well. Thanks!

- having had many travel trailers the water pump is usually in a cabinet or under a bed or couch with a lot of plastic water lines near where you screw the water hose into the side of the trailer. and they are usually a preset psi from the factory so that is usually nothing to have to worry about and most have an on off switch located in the traier by the kitchen sink.And if the hot water heater is no good look into a tankless water heater it will save you money in the long run but initially you have to have a vent installed up through the roof away from a roof air vent. Another suggestion everytime you move a travel trailer they get the crap pounded out of them and someone needs to go up on the roof with a ladder and/or a plank that goes across the width so there is no weight standing on a roof to make dents or pop seams. Use some plastic stuff like plasticote available at wal mart after you move the trailer and set it up go up and make sure to double coat any of the seams that need it. I crank the heat up inside the trailer and do a double coat the heat rising will put a skin on the plasticote in a few hours instead of 12 or more. and the double coat gets any cracks missed the first time around. After that check it once a year if the trailer stays there.

- Q: TDH what units are present in the pump parameters?

- TDH, Total, Discharge, Head, that means the head, the unit is usually feet. 1 feet =0.3048 meters.

- Q: I have a 1997 ford ranger, during last week i noticed that the temperature started to go up, i noticed that the coolant recovery tank was empty so i added coolant and it fixed the problem, but a day later i noticed that the tank was empty again since it started to overheat again. This time i let the engine cool off and checked the radiator water levels and noticed it was dry with no water, so i added water and noticed that i was leaking from what it seems the water pump (im guessing its the water pump because is behind the engine fan, behind the belts, its hard to see), Does anyone have a possible explanation or suggestion of what i should do? Thank you i would really appreciate it.

- Hopefully you didn't run it to long while it was overheating. Your going to have to replace the waterpump from your discription it sounds like it's bad. It's not a hard job to do if your mechanically inclined. If not buy the repair manual to do it yourself or pay a professional.

- Q: Hi, my water pump isn't working in my rover 400i V reg 99 model......does anyone know where under my bonet this is located and whether it's easy done at home?

- water pumps are never an easy fix. most the time you have to take the fan off, and the radiator as well so a person has room to work. MOST water pumps are in front of the motor, towards the bottom. If you follow your radiator hoses you will find it.

- Q: My mechanic said I have a very small coolant leak and that in the future I might need to replace it.He said I should keep an eye on my coolant level.Anyone like to comment on how how a quot;small leakmight develop into a quot;major leakthat needs to be urgently addressed?He also said that to replace my water pump, he would charge $400. Is this expensive?(I have a 1996 VW Jetta)

- The water pump leaks to warn you that it is about to go bad, meaning that you will overheat. Keeping an eye on the coolant is a good temporary course of action but this needs to be fixed before you ruin the engine. I believe your water pump is driven by the timing belt and that is a complex job. $400 is about right, and have him change the timing belt and thermostat also.

- Q: I have replaced my water heater and water pump because the owner before me didnt drain it over the winter... but know the water suputers when the pump is on.. when I hook up to city water it works great.. I have not been able to find any leaks.. any ideas???

- A lot of the pumps for RVs do cause a slight sputter, Try compleatly filling the water tank, then turning the pump on,. Allow a few minutes to build up pressure and fill the hot water tank, If the sputtering slows, or compleatly stops, your ok. You have to remember that a lot of after market pumps don't work quite as well as an OEM pump. If it's a real bad sputtering, You might need to return the pump.

Send your message to us

Single Stage Double Suction Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords