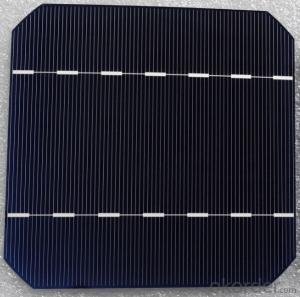

Silicon Wafer Solar Cell Panels - High Quality A Grade Mono Crystalline 5V 18.4% Solar Cells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

hot sale solar cell

1.16.8%~18.25% high efficiency

2.100% checked quality

3.ISO9001/ISO14001/TUV/CE/UL

4.stable performance

We can offer you the best quality products and services, don't miss !

POLY6'(156*156)

Polycrystalline Silicon Solar cell

Physical Characteristics

Dimension: 156mm×156mm±0.5mm

Diagonal: 220mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating (silicon nitride); Aluminum back surface field;

1.5mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 51mm . Distance between bus bars :51mm .

Electrical Characteristics

Efficiency(%) | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 | 16.80 | 16.60 | 16.40 | 16.20 | 16.00 | 15.80 | 15.60 |

Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 | 4.04 | 3.99 | 3.94 | 3.90 | 3.86 | 3.82 |

Umpp(V) | 0.530 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.514 | 0.511 | 0.509 | 0.506 | 0.503 | 0.501 |

Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.990 | 7.938 | 7.876 | 7.813 | 7.754 | 7.698 | 7.642 | 7.586 |

Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.620 | 0.618 | 0.617 | 0.615 | 0.613 | 0.611 | 0.609 |

Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 | 8.419 | 8.356 | 8.289 | 8.220 | 8.151 | 8.083 |

MONO5'(125*125mm)165

Monocrystalline silicon solar cell

Physical Characteristics

Dimension: 125mm×125mm±0.5mm

Diagonal: 165mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating(silicon nitride); Aluminum back surface field;

1.6mmwide bus bars; 2.5mm wide soldering pads;

Distance between bus bars: 61mm . Distance between bus bars :61mm .

Electrical Characteristics

Efficiency(%) | 19.40 | 19.20 | 19.00 | 18.80 | 18.60 | 18.40 | 18.20 | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 |

Pmpp(W) | 2.97 | 2.94 | 2.91 | 2.88 | 2.85 | 2.82 | 2.79 | 2.76 | 2.73 | 2.70 | 2.67 | 2.62 |

Umpp(V) | 0.537 | 0.535 | 0.533 | 0.531 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.515 | 0.513 | 0.509 |

Impp(A) | 5.531 | 5.495 | 5.460 | 5.424 | 5.408 | 5.382 | 5.355 | 5.328 | 5.291 | 5.243 | 5.195 | 4.147 |

Uoc(V) | 0.637 | 0.637 | 0.636 | 0.635 | 0.633 | 0.630 | 0.629 | 0.629 | 0.628 | 0.626 | 0.626 | 0.625 |

Isc(A) | 5.888 | 5.876 | 5.862 | 5.848 | 5.839 | 5.826 | 5.809 | 5.791 | 5.779 | 5.756 | 5.293 | 5.144 |

FAQ:

Q:How can i get some sample?

A:Yes , if you want order ,sample is not a problem.

Q:How about your solar panel efficency?

A: Our product efficency around 17.25%~18.25%.

Q:What’s the certificate you have got?

A: we have overall product certificate of ISO9001/ISO14001/CE/TUV/UL

- Q: What is the role of solar silicon wafers in reducing water consumption?

- Solar silicon wafers play a crucial role in reducing water consumption by enabling the production of solar panels, which generate electricity without the need for water-intensive cooling systems. This helps alleviate the strain on water resources, as traditional power generation methods often require substantial amounts of water for cooling purposes.

- Q: Is the thickness of solar cell silicon wafer certain? Specifically how much

- The rest is just the substrate, it doesn't work. Do not understand, then you can look at the film thickness of the battery, you will understand.

- Q: What is a semiconductor silicon device tester

- First of all the circuit insulator carrier plays a supporting role in the insulation layer of the circuit is called the substrate (like P type semiconductor) to participate in the work of the collection circuit to take the CMOS process Nmos substrate are connected with the substrate

- Q: Can solar silicon wafers be used in mobile or portable solar chargers?

- Yes, solar silicon wafers can be used in mobile or portable solar chargers. These chargers utilize photovoltaic cells made from silicon wafers to convert sunlight into electricity, allowing for the charging of various mobile devices on the go.

- Q: Why do you use a concentrated sulfuric acid and hydrogen peroxide to wash silicon?

- But it is best not to use, the use of water under normal conditions and these two kinds of things can be caustic clean silicon, 100% recycled mortar is not the problem, but this requires tens of thousands of cost and appropriate design, I am clean

- Q: Can solar silicon wafers be used in solar-powered street lighting systems?

- Yes, solar silicon wafers can be used in solar-powered street lighting systems. These wafers are commonly used in the production of solar panels, which generate electricity from sunlight. By utilizing solar silicon wafers in street lighting systems, solar energy can be harnessed during the day and stored in batteries to power the lights during the night, providing an eco-friendly and sustainable lighting solution.

- Q: How are solar silicon wafers protected from handling errors during installation?

- Solar silicon wafers are protected from handling errors during installation through several measures. Firstly, they are typically packaged in protective materials such as anti-static bags or foam to prevent any physical damage or electrostatic discharge. Additionally, during installation, special handling techniques are employed to minimize the risk of mishandling or dropping the wafers. These techniques may include using cleanroom gloves, avoiding direct contact with the wafers' active surfaces, and using precision tools or equipment for their placement. Overall, these precautions aim to safeguard the delicate wafers and ensure their proper installation without any handling errors.

- Q: What is the purity level of the silicon used in solar silicon wafers?

- The purity level of the silicon used in solar silicon wafers is typically around 99.9999%, also known as 6N purity.

- Q: Are solar silicon wafers affected by snow or ice accumulation?

- Yes, solar silicon wafers can be affected by snow or ice accumulation. Snow or ice covering the surface of the solar panels can block sunlight from reaching the silicon wafers, reducing their efficiency and power output. Regular removal of snow or ice from the panels is recommended to ensure optimal performance.

- Q: Are there any alternatives to solar silicon wafers?

- Yes, there are alternatives to solar silicon wafers. Some alternative materials that can be used for solar cells include thin-film technologies such as cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and organic photovoltaics (OPV). These alternatives offer different advantages and disadvantages compared to silicon wafers, such as lower production costs, flexibility, and higher efficiency in certain conditions. However, silicon wafers remain the dominant material for solar cells due to their well-established technology and high efficiency.

Send your message to us

Silicon Wafer Solar Cell Panels - High Quality A Grade Mono Crystalline 5V 18.4% Solar Cells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords