Industrial Silicon Wafer Solar Cells / 156mm Mono Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

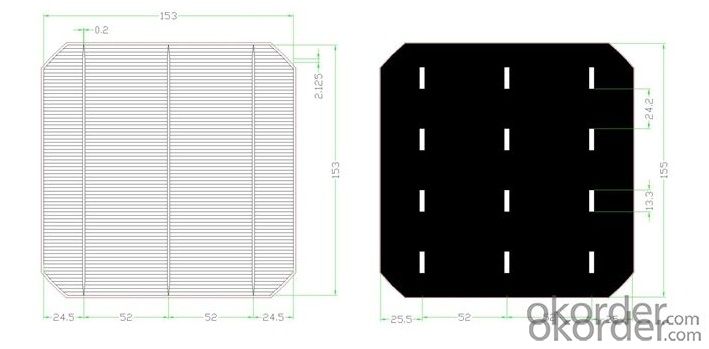

Monocrystalline Silicon Solar Cell/156mm Mono Solar Cell

Type:156M

Appearance:156×1565㎜±0.5mm;diagonal:R=100mm

Main fence wide:1.4-1.5mm back electrode wide:2-2.5mm

Fence line qty:90

Cell thickness:220um±20um

Eff(%) | 18.00- 18.10 | 18.10- 18.20 | 18.20- 18.30 | 18.30- 18.40 | 18.40- 18.50 | 18.50- 18.60 | 18.60- 18.70 | 18.70- 18.80 | 18.80- 18.90 | 18.9- 19.0 | 19.1- 19.1 | 19.1- 19.2 |

Pm(W) | 4.30 | 4.33 | 4.35 | 4.37 | 4.40 | 4.42 | 4.44 | 4.47 | 4.49 | 4.52 | 4.54 | 4.56 |

Isc(A) | 8.71 | 8.73 | 8.76 | 8.77 | 8.78 | 8.82 | 8.83 | 8.85 | 8.86 | 8.88 | 8.9 | 8.93 |

Im(A) | 8.19 | 8.21 | 8.24 | 8.26 | 8.30 | 8.33 | 8.35 | 8.39 | 8.42 | 8.45 | 8.47 | 8.51 |

Voc(V) | 0.630 | 0.631 | 0.632 | 0.633 | 0.634 | 0.634 | 0.635 | 0.636 | 0.637 | 0.637 | 0.638 | 0.64 |

Vm(V) | 0.527 | 0.528 | 0.529 | 0.531 | 0.531 | 0.532 | 0.534 | 0.534 | 0.535 | 0.536 | 0.537 | 0.538 |

FF(%) | 78.6 | 78.7 | 78.8 | 79.0 | 79.2 | 79.3 | 79.5 | 79.6 | 79.8 | 80 | 80 | 80 |

Picture show

Shipping

1. Shipment shall be made only after PAYMENT is received.

2. Please do inform us your DETAILED ADDRESS AND CONTACT INFOMATION before shipment.

3. Shipment shall be made in THREE WORKING DAYS.

2. Shipment shall be via EMS, DHL, Fedex,UPS etc.

- Q: How is a power output measured in a solar silicon wafer?

- The power output of a solar silicon wafer is typically measured by connecting it to a load resistance and measuring the voltage and current generated by the wafer. The power output is then calculated by multiplying the voltage and current values.

- Q: What is the role of passivation on solar silicon wafers?

- The role of passivation on solar silicon wafers is to minimize surface recombination and increase the efficiency of the solar cell. Passivation helps to reduce defects and traps on the surface of the wafer, allowing for better charge carrier separation and collection, which ultimately leads to improved performance of the solar cell.

- Q: How are solar silicon wafers protected from transportation damage?

- Solar silicon wafers are typically protected from transportation damage through various measures, such as packaging them in special containers or boxes that provide cushioning and shock absorption. These containers often include foam inserts or other materials that prevent the wafers from moving or vibrating during transit, minimizing the risk of breakage or cracking. Additionally, some manufacturers may use specialized handling procedures and equipment to ensure safe transportation of the wafers, reducing the potential for damage during loading, unloading, or movement.

- Q: Can solar silicon wafers be reused or repurposed after their lifespan in a solar panel?

- Yes, solar silicon wafers can be reused or repurposed after their lifespan in a solar panel. While they may no longer be suitable for generating electricity in solar panels, these wafers can be recycled to extract valuable materials such as silicon, silver, and glass. The extracted materials can then be used in various industries, including electronics, semiconductors, and glass manufacturing, promoting a more sustainable approach to resource utilization.

- Q: Can solar silicon wafers be used in off-grid solar applications?

- Yes, solar silicon wafers can be used in off-grid solar applications. These wafers are commonly used in the production of solar panels, which can generate electricity from sunlight. Off-grid solar systems are designed to operate independently of the traditional power grid, making them a suitable application for solar silicon wafers as they can harness solar energy to power various appliances and devices in remote locations.

- Q: How long does it take to produce a solar silicon wafer?

- The production time for a solar silicon wafer can vary depending on various factors, such as the manufacturing process and the desired quality and specifications. However, on average, it takes around 2 to 4 weeks to produce a solar silicon wafer from start to finish.

- Q: Can solar silicon wafers be used in smart grid systems?

- Yes, solar silicon wafers can be used in smart grid systems. Solar silicon wafers are the key component of solar cells used in photovoltaic systems, which can generate electricity from sunlight. Smart grid systems aim to enhance the efficiency, reliability, and sustainability of electricity distribution and consumption. By integrating solar silicon wafers into smart grid systems, solar energy can be harnessed and integrated into the grid, contributing to renewable energy generation and promoting a cleaner and more sustainable power supply.

- Q: What is the expected growth rate for the solar silicon wafer market?

- The expected growth rate for the solar silicon wafer market is projected to be significant, with estimates suggesting an annual growth rate of around 6% to 8% over the next few years. This growth is driven by the increasing adoption of solar energy, the push for clean and renewable sources of power, and advancements in solar technology.

- Q: What is the average reflectivity of a solar silicon wafer?

- The average reflectivity of a solar silicon wafer is typically around 30%.

- Q: How do solar silicon wafers perform in high-pollution environments?

- Solar silicon wafers generally perform well in high-pollution environments. While pollution can potentially reduce the efficiency of solar panels over time by decreasing the amount of sunlight reaching the cells, manufacturers have taken measures to mitigate this impact. Anti-reflective coatings and regular cleaning can help maintain optimal performance. Additionally, advancements in technology and materials have made solar panels more resilient to pollution, enabling them to continue generating electricity effectively even in polluted areas.

Send your message to us

Industrial Silicon Wafer Solar Cells / 156mm Mono Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords