Rhino Steel Structures:Cheap Steel Structure Warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

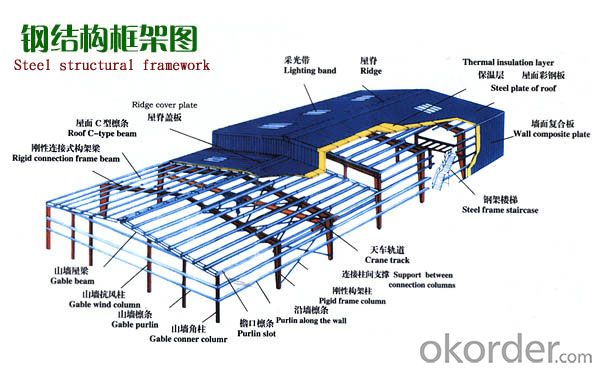

Steel Structure

We can design,fabricate and install all kinds of steel structure buildings.

Item Name: Steel Structure

Size: Length,Width and height according to customer's requirements.

Material: Q235 and Q345.

Surafce: hot dip galvanize or Painted

Drawings: We can make the quotation according to customer's drawing.

We can also make the design and quotation according to customer's requirements.

We can offer all the detailed drawings for installation and fabrication.

Packing: Decided by buyer.

Load in to 40ft GP,20ft GP or 40HQ or 40OT.

Carbon structural steel: Q195, Q215, Q235, Q255, Q275, etc.

High-strength low-alloy structural steel

Quality carbon structural steel and alloy structural steel

Special purpose steel

- Q:What are the different types of steel used in structures?

- There are various types of steel used in structures, including carbon steel, stainless steel, and alloy steel. Carbon steel is the most common and versatile type, with different grades like A36 and A572 used for different applications. Stainless steel is known for its corrosion resistance and is often used in environments with high moisture or chemical exposure. Alloy steel is a combination of carbon steel and other elements, providing enhanced strength and durability for specialized applications.

- Q:What is the difference between bolted and welded connections?

- Structural components can be joined together using either bolted or welded connections. These two methods differ in how they transmit forces and the ease of installation and removal. Bolted connections involve using bolts, nuts, and washers to fasten components together. The components are typically pre-drilled with matching holes, and the bolts are tightened to a specified torque to create the joint. Bolted connections offer advantages such as easy assembly and disassembly, adjustability, and the ability to replace individual components if needed. They also allow for easier inspection and maintenance. However, bolted connections may require more space and are generally not as strong as welded connections. On the other hand, welded connections involve fusing components together using heat and pressure. This creates a permanent joint that is highly resistant to shear and bending forces. Welded connections are typically stronger and more rigid than bolted connections, making them suitable for high load-bearing applications. They are also more compact and visually pleasing since there are no visible bolts or fasteners. However, welded connections are difficult to modify or repair, and the welding process requires skilled labor and specialized equipment. In summary, bolted connections offer ease of installation, adjustability, and the ability to replace components, while welded connections provide superior strength, rigidity, and a more compact design. The choice between the two methods depends on specific application requirements, such as load-bearing capacity, ease of maintenance, and the availability of skilled labor and equipment.

- Q:How do steel structures perform in terms of resistance to seismic events?

- Steel structures generally perform well in terms of resistance to seismic events. Due to their high strength-to-weight ratio and ductility, steel frames can absorb and dissipate seismic energy effectively, reducing the risk of structural failure during earthquakes. Steel's flexibility allows the structure to sway and deform under seismic forces, thus minimizing damage. Additionally, steel structures can be designed and reinforced to meet specific seismic design criteria, further enhancing their performance and ensuring the safety of occupants.

- Q:How to consider the influence of base displacement on steel structure

- When performing the structural search and acceptance, the steel structure is completed after installation. Often issued axis displacement, the vertical deviation is too large and the height of the column column below the design elevation. In the high-rise steel structure engineering, it is also found that the spacing of each column is too large or too small, and it is often found that the top elevation at both ends of the beam is inconsistent when searching the top of each layer.

- Q:How are steel structures designed to be resistant to wind-induced vibrations?

- To minimize the effects of wind-induced vibrations, steel structures are carefully engineered and constructed. The primary approach involves designing the structure to be aerodynamically stable. This entails considering the shape and configuration of the steel components to mitigate wind pressure and turbulence. Techniques such as employing streamlined shapes or incorporating wind deflectors and vortex generators redirect the wind flow and reduce the forces acting on the structure. Material selection is also crucial. High-strength steel with good ductility and fatigue resistance is commonly chosen to maintain structural integrity under dynamic wind loads. The steel members are appropriately sized and reinforced to withstand expected wind forces and minimize the risk of fatigue failure. In addition, the connections between steel members are designed to be rigid and robust. This ensures proper load transfer and minimizes any potential movement or displacement. Welded connections are often preferred due to their greater stiffness and fatigue resistance compared to bolted connections. To dissipate the energy generated by wind-induced vibrations, damping devices can be integrated into the steel structure. Tuned mass dampers or dampening plates absorb and dissipate vibrational energy, reducing the risk of resonance and structural damage. The design process heavily relies on computer modeling and simulation techniques to analyze the structural response to wind loads and optimize the design. Wind tunnel tests may also be conducted to validate the design and ensure its performance under various wind conditions. In conclusion, designing steel structures to withstand wind-induced vibrations requires a comprehensive understanding of aerodynamic forces, structural behavior, and material properties. By implementing these design principles and techniques, steel structures can effectively resist wind loads, ensuring the safety and stability of the building.

- Q:How are steel structures designed to accommodate equipment and machinery?

- Steel structures are designed to accommodate equipment and machinery by considering factors such as load capacity, weight distribution, and vibration control. Engineers carefully analyze the requirements of the equipment or machinery being installed, and then design the steel structure accordingly. This involves determining the appropriate size, shape, and placement of support beams, columns, and foundations, ensuring they can adequately support the weight and movement of the equipment. Additionally, provisions for electrical wiring, plumbing, and ventilation are integrated into the design to ensure seamless integration of the equipment and machinery into the steel structure.

- Q:How are steel structures designed for efficient use of water and energy resources?

- Steel structures can be designed to promote the efficient use of water and energy resources in several ways. Firstly, the construction of steel buildings often involves the use of recycled steel, which reduces the energy and water requirements of the manufacturing process. Additionally, the durability and longevity of steel structures minimize the need for frequent repairs or replacements, saving both water and energy resources in the long term. In terms of water efficiency, steel structures can incorporate various design features to minimize water consumption. For example, rainwater harvesting systems can be integrated into the building's design, allowing for the collection and storage of rainwater for non-potable uses such as irrigation or toilet flushing. This reduces the reliance on municipal water supplies and preserves freshwater resources. Furthermore, steel buildings can be designed with efficient plumbing systems that include low-flow fixtures and water-saving technologies. These features help to reduce water consumption by minimizing waste and optimizing water use. Additionally, the use of water-efficient landscaping, such as native plants or drought-tolerant vegetation, can further reduce water requirements for irrigation. In terms of energy efficiency, steel structures can be designed with high levels of insulation, efficient glazing systems, and advanced building envelope technologies. These features help to minimize heat transfer and improve the overall energy performance of the building, reducing the need for heating and cooling. By optimizing thermal comfort and reducing energy demand, steel structures can contribute to significant energy savings. Moreover, steel buildings can incorporate renewable energy systems such as solar panels or wind turbines to generate clean and sustainable energy on-site. These renewable energy sources can offset the building's energy consumption and reduce reliance on fossil-fuel-based energy, further conserving resources and reducing greenhouse gas emissions. In conclusion, steel structures can be designed to maximize water and energy efficiency through the use of recycled materials, rainwater harvesting, water-saving technologies, efficient plumbing systems, insulation, renewable energy sources, and other sustainable design features. By considering these factors, steel buildings can significantly contribute to the conservation of water and energy resources, making them an environmentally responsible choice for construction.

- Q:What are the design considerations for steel roofs?

- Some design considerations for steel roofs include structural stability, weather resistance, longevity, and aesthetic appeal. Steel roofs need to be designed to withstand various environmental factors such as wind, snow, and rain. The structural design should ensure that the roof can support its own weight and any potential loads, such as heavy snowfall. Additionally, proper insulation and ventilation are crucial to prevent condensation and ensure energy efficiency. The choice of steel material, coating, and finishes also affects the roof's durability and ability to resist corrosion. Lastly, designing steel roofs to complement the overall architectural style and desired aesthetics of the building is important for visual harmony.

- Q:What are the considerations when designing steel structures for cleanrooms and laboratories?

- When designing steel structures for cleanrooms and laboratories, several key considerations must be taken into account. Firstly, the materials used for the steel structure should be corrosion-resistant, as the environment within cleanrooms and laboratories often involves exposure to chemicals and moisture. Additionally, the design should incorporate proper ventilation systems to ensure the removal of contaminants and maintain the desired air quality. The structure should also prioritize ease of cleaning and maintenance, with smooth surfaces and minimal crevices where dirt or particles can accumulate. Lastly, the design must comply with stringent safety regulations and standards to ensure the protection of personnel and the integrity of the facility.

- Q:What are the common misconceptions about steel structures?

- There are several common misconceptions about steel structures that need to be clarified. One common misconception is that steel structures are not as durable as concrete structures. In reality, steel structures are incredibly durable and can withstand extreme weather conditions, seismic activity, and even fire. Steel is known for its strength and resilience, making it an excellent choice for construction. Another misconception is that steel structures are more expensive than other construction materials. While steel may have a higher initial cost, it is important to consider the long-term benefits. Steel structures require less maintenance and have a longer lifespan compared to other materials. Additionally, steel is recyclable, making it an environmentally friendly choice. Some people also believe that steel structures are not aesthetically pleasing. However, with advancements in design and technology, steel structures can be customized to fit any architectural style and can be visually appealing. The flexibility of steel allows for unique and innovative designs, making it a popular choice among architects and designers. Lastly, there is a misconception that steel structures are noisy and prone to rust. While it is true that steel can produce noise when it expands and contracts due to temperature changes, proper insulation and soundproofing techniques can minimize this issue. Moreover, steel structures can be coated with protective finishes to prevent rust and corrosion, ensuring their longevity. Overall, it is important to dispel these misconceptions and recognize the many advantages of steel structures. They offer durability, cost-effectiveness, aesthetic appeal, and sustainability, making them a popular choice in the construction industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rhino Steel Structures:Cheap Steel Structure Warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords