JIS Equal Angle Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of JIS Equal Angle

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

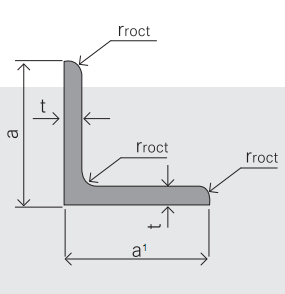

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

6. Material details:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

Usage & Applications of JIS Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of JIS Equal Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: What are the standard specifications for steel angles?

- The standard specifications for steel angles are defined by various organizations, including the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). These specifications ensure that steel angles meet certain quality and dimensional requirements. One of the most commonly used specifications for steel angles is ASTM A36, which covers carbon structural steel shapes. According to this specification, steel angles should have a minimum yield strength of 36,000 psi (pounds per square inch) and a minimum tensile strength of 58,000 to 80,000 psi. The dimensions of the angles are specified in terms of leg length, thickness, and angle size, which can range from 1/2 inch to 8 inches. Another widely used specification is ASTM A572, which covers high-strength low-alloy structural steel shapes. Steel angles under this specification should have a minimum yield strength of 50,000 psi and a minimum tensile strength of 65,000 to 80,000 psi. The dimensions of the angles are similar to ASTM A36. ISO also provides standards for steel angles, such as ISO 657-1 and ISO 657-5. These standards specify dimensions, tolerances, and technical requirements for hot-rolled steel angles. ISO 657-1 covers general purpose angles, while ISO 657-5 covers unequal leg angles. In addition to these standards, steel angles may also be subject to specific requirements based on their intended application or industry. For example, angles used in construction or engineering projects may need to meet additional specifications set by local building codes or design guidelines. It is important to consult the relevant standards and specifications to ensure that steel angles meet the necessary requirements for a particular application, as these standards help ensure the quality, strength, and dimensional accuracy of the angles.

- Q: Are steel angles suitable for balcony railings?

- Yes, steel angles are suitable for balcony railings. Steel angles are strong, durable, and resistant to corrosion, making them an ideal choice for outdoor applications like balcony railings. They provide excellent structural support and can withstand heavy loads, ensuring the safety of individuals leaning on or using the balcony railing. Additionally, steel angles can be easily fabricated and customized to fit the specific design requirements of the balcony, making them a versatile option. Overall, steel angles are a reliable and long-lasting choice for balcony railings.

- Q: How do you prevent steel angles from warping?

- To prevent the warping of steel angles, there are several measures that can be taken: 1. Store the steel angles in a dry environment and avoid moisture exposure. This will prevent rust and warping. Use pallets or racks to store them horizontally, minimizing bending stress. 2. Employ controlled cooling techniques during fabrication. Rapid temperature changes can induce warping, so it is important to cool gradually. Air cooling or controlled cooling baths can help avoid thermal stresses and minimize warping. 3. Minimize heat input during welding. Excessive heat can cause localized thermal expansion and contraction, leading to warping. Utilize proper welding techniques such as shorter welding times, smaller weld beads, and intermittent welding to control the temperature gradient and minimize heat input. 4. Consider preheating and post-welding stress relief for thicker or high-strength steel angles. Preheating before welding can reduce the risk of warping, and post-welding stress relief heat treatments can relieve any residual stresses and prevent warping. 5. Handle and transport the steel angles properly. Adequately support and secure them during transit to avoid bending or flexing. Avoid dropping or mishandling, as this can introduce structural deformations that lead to warping. By implementing these preventive measures, the risk of steel angles warping can be minimized, ensuring their structural integrity for various applications.

- Q: What is the angle iron back machine?

- In the structure of angle steel tower, a large number of iron fittings are used. In order to make the connection tight, it is necessary to shovel or clean the angle iron of the iron connecting piece, and the NC angle steel back shovel is just for the purpose of cleaning the angle iron. For more detailed information, you can look at the super CNC website, they are professional manufacturers.

- Q: Are there any industry standards or certifications for steel angles?

- Steel angles have industry standards and certifications. The main standard for steel angles is the ASTM standard, specifically the ASTM A36 specification. This specification outlines the necessary chemical composition, mechanical properties, and dimensional tolerances for structural steel angles. Aside from ASTM, other organizations like AISC and SJI also provide guidelines and standards for steel angles used in construction and structural engineering. These standards guarantee that steel angles meet specific requirements in terms of quality, strength, and performance. Moreover, certifications like ISO 9001:2015 and ISO 14001:2015 are widely recognized in the steel industry. These certifications indicate that a manufacturer has implemented a quality management system and complies with environmental management standards. Adhering to these industry standards and certifications is crucial for manufacturers, suppliers, and construction professionals. It ensures the dependability and safety of steel angles in various applications.

- Q: What are the different grades of steel used for manufacturing steel angles?

- There are several different grades of steel that are commonly used for manufacturing steel angles. These include: 1. Mild Steel: This is the most common grade of steel used for manufacturing steel angles. It has a low carbon content and is relatively inexpensive. Mild steel angles are suitable for a wide range of applications and have good weldability and formability. 2. High-strength low-alloy (HSLA) steel: This grade of steel contains small amounts of alloying elements such as copper, vanadium, or niobium, which enhance its strength and toughness. HSLA steel angles are commonly used in structural applications where high strength and durability are required. 3. Stainless Steel: Stainless steel angles are manufactured using alloys that contain a high percentage of chromium, which provides excellent corrosion resistance. These angles are commonly used in environments where corrosion is a concern, such as coastal areas or chemical plants. 4. Carbon Steel: Carbon steel angles are made from a combination of iron and carbon, with carbon content typically ranging from 0.05% to 2.1%. The higher the carbon content, the stronger and harder the steel. Carbon steel angles are commonly used in construction and machinery manufacturing. 5. Alloy Steel: Alloy steel angles are made by adding various alloying elements such as manganese, nickel, chromium, or molybdenum to carbon steel. These additions improve the strength, hardness, and resistance to wear and corrosion of the steel. Alloy steel angles are commonly used in heavy-duty applications such as mining equipment or industrial machinery. The choice of grade of steel for manufacturing steel angles depends on the specific requirements of the application, including the desired strength, durability, corrosion resistance, and cost.

- Q: Can steel angles be used for green building projects?

- Absolutely! Green building projects can definitely utilize steel angles. Steel is an incredibly sustainable and eco-friendly material that boasts durability, recyclability, and energy efficiency. When it comes to construction, steel angles, also referred to as L-shaped steel, are widely recognized for their strength and versatility. They can be employed in a multitude of ways in green building projects, including framing, providing structural support, and reinforcement. One of the major advantages of steel angles is that they are often manufactured using recycled steel. This practice reduces the need for extracting new raw materials and effectively minimizes waste. Moreover, steel can be recycled indefinitely without compromising its strength or quality, making it an incredibly sustainable choice. By incorporating recycled steel angles into green building projects, carbon emissions can be reduced and natural resources can be conserved. Additionally, steel is an energy-efficient material that contributes to the overall energy efficiency of a building. Steel angles can be utilized in the construction of energy-efficient systems, such as structures for mounting solar panels, wind turbine towers, and other renewable energy infrastructure. The strength and durability of steel also enable the design of lightweight structures, which significantly reduces the amount of energy required for construction and transportation. Furthermore, steel angles exhibit resistance to pests, fire, and moisture, ensuring the longevity and durability of green buildings. Their versatility enables seamless integration with other sustainable building materials, such as recycled concrete, wood, and glass, further enhancing the environmental performance of the project. To summarize, the utilization of steel angles in green building projects is unquestionably feasible. Their sustainability, durability, recyclability, and energy efficiency make them an ideal choice for constructing environmentally friendly and sustainable buildings.

- Q: Can steel angles be used for framing or supporting partitions?

- Yes, steel angles can be used for framing or supporting partitions. Steel angles are commonly used in construction due to their strength and durability. They provide excellent support and stability, making them suitable for framing or supporting partitions in various structures.

- Q: What is the maximum slope for a steel angle?

- The maximum slope for a steel angle depends on various factors such as the size, shape, and thickness of the angle. However, in general, steel angles are designed to withstand vertical loads and provide stability in structural applications. Therefore, the maximum slope for a steel angle is typically limited to angles less than 45 degrees. Going beyond this angle may compromise the structural integrity of the angle and increase the risk of failure. It is important to consult engineering codes, standards, and specifications to determine the specific maximum slope for a particular steel angle in a given application.

- Q: How are steel angles protected against abrasion?

- Steel angles can be protected against abrasion through various methods, such as applying anti-abrasion coatings, using rubber or plastic lining, or incorporating sacrificial wear plates. These protective measures help to minimize the wear and tear caused by friction and ensure the longevity and durability of the steel angles.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; middle east; South Korea; Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30%-45% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

JIS Equal Angle Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords