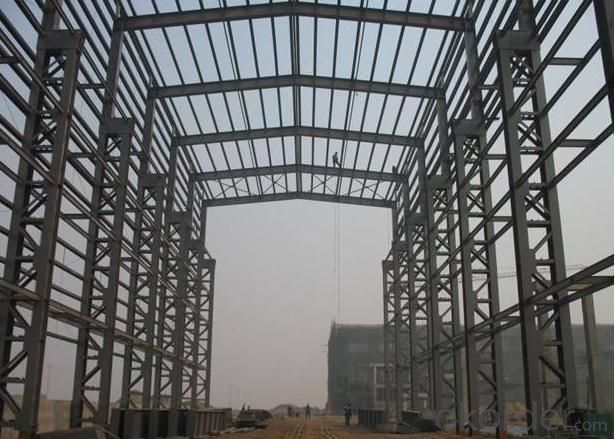

Heavy steel Workshop

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 sqare meters m.t.

- Supply Capability:

- 50000 Square Meters/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of heavy steel workshop

The project is smelting heavy steel workshop

Maximum crane: 100 tons

Single building area: 30,000 square meters

1. GB standard material

2. High Structural safety and reliability

3. The production can reach GB/JIS/ISO/ASME standard

Packaging & Delivery of heavy steel workshop

1. According to the project design and the component size, usually the main component parts are nude packing and shipped by bulk vessel. And the small parts are packed in box or suitable packages and shipped by containers.

2. This will be communicated and negotiated with buyer according to the design.

Engineering Design Software of heavy steel workshop

Tekla Structure \ AUTO CAD \ PKPM software etc

⊙Complex spatial structure project detailed design

⊙Construct 3D-model and structure analysis. ensure the accuracy of the workshop drawings

⊙Steel structure detail ,project management, automatic Shop Drawing, BOM table automatic generation system.

⊙Control the whole structure design process,we can obtain higher efficiency and better results

Technical support of heavy steel workshop

|

Worker |

Rate of frontline workers with certificate on duty reaches 100% |

|

Welder |

186 welders got AWS & ASME qualification 124 welders got JIS qualification 56 welders got DNV &BV qualification |

|

Technical inspector |

40 inspectors with UT 2 certificate 10 inspectors with RT 2 certificate 12 inspectors with MT 2 certificate 3 inspectors with UT3 certificate |

|

Engineer |

21 engineers with senior title 49 engineers with medium title 70 engineers with primary title. 61 First-Class Construction Engineers 182 Second-Class Construction Engineers |

|

International certification |

10 engineers with International Welding engineer, 8 engineers with CWI. |

Production Flow of heavy steel workshop

Material preparation—cutting—fitting up—welding—component correction—rust removal—paint coating—packing—to storage and transportation (each process has the relevant inspection)

steel structure cutting machine steel structure (H beam) fitting up machine steel structure welding machine steel structure painting area

Usage/Applications of steel structure/steel frame

*Characters of Structure Steel

1. Steel is characterized by high strength, light weight, good rigidity, strong deformation capacity, so it is suitable for construction of large-span, super high and super-heavy buildings particularly;

2. It with good homogeneous and isotropic, is an ideal elastomer which perfectly fits the application of general engineering;

3. The material has good ductility and toughness, so it can have large deformation and it can well withstand dynamic loads;

4. Steel structure’s construction period is short;

5. Steel structure has high degree of industrialization and can realize-specialized production with high level of mechanization.

*Steel structure application

1. Heavy industrial plants: relatively large span and column spacing; with a heavy duty crane or large-tonnage cranes; or plants with 2 to 3 layers cranes; as well as some high-temperature workshop should adopt steel crane beams, steel components, steel roof, steel columns, etc. up to the whole structure.

2. Large span structure: the greater the span of the structure, the more significant economic benefits will have by reducing the weight of the structure

3. Towering structures and high-rise buildings: the towering structure, including high-voltage transmission line towers, substation structure, radio and television emission towers and masts, etc. These structures are mainly exposed to the wind load. Besides of its light weight and easy installation, structure steel can bring upon with more economic returns by reducing the wind load through its high-strength and smaller member section.

4. Structure under dynamic loads: As steel with good dynamic performance and toughness, so it can be used directly to crane beam bearing a greater or larger span bridge crane

5. Removable and mobile structures: Structure Steel can also apply to movable Exhibition hall and prefabricated house etc by virtue of its light weight, bolt connection, easy installation and uninstallation. In case of construction machinery, it is a must to use structure steel so as to reduce the structural weight.

6. Containers and pipes: the high-pressure pipe and pipeline, gas tank and boiler are all made of steel for the sake of its high strength and leakproofness

7. Light steel structure: light steel structures and portal frame structure combined with single angle or thin-walled structural steel with the advantages of light weight, build fast and steel saving etc., in recent years has been widely used.

8. Other buildings: Transport Corridor, trestle and various pipeline support frame, as well as blast furnaces and boilers frameworks are usually made of steel structure.

All in all, according to thereality, structure steel is widely used for high, large, heavy and light construction.

- Q: How are steel structures used in access and safety systems?

- Steel structures are commonly used in access and safety systems due to their strength, durability, and versatility. Steel can be used to construct various components of these systems, such as platforms, walkways, stairs, and guardrails. These structures provide safe and reliable access to elevated areas, ensuring the safety of workers and preventing accidents. Additionally, steel's resistance to corrosion makes it suitable for outdoor applications, making it an ideal material for access and safety systems in various industries.

- Q: What are the design considerations for steel railway stations?

- When designing steel railway stations, several key considerations need to be taken into account to ensure efficient and functional infrastructure. These design considerations include: 1. Structural Integrity: Steel is a popular choice for railway station construction due to its strength and durability. The design must ensure that the steel structure can withstand the constant loads and stresses imposed by trains, passengers, and various weather conditions. 2. Accessibility: Railway stations should be accessible to all passengers, including those with disabilities. The design should incorporate features like ramps, elevators, and tactile paving to ensure easy movement and navigation for everyone. 3. Passenger Flow and Safety: Efficient movement of passengers within the station is crucial to avoid congestion and potential accidents. The design should consider factors such as platform width, ticketing areas, waiting spaces, and clear signage to guide passengers and maintain a smooth flow. 4. Platform and Track Design: The platform and track layout should be designed to accommodate different types of trains and their specific requirements. Factors such as train length, curve radius, and platform height should be carefully considered to ensure safe boarding and alighting of passengers. 5. Natural Lighting and Ventilation: Maximizing the use of natural light and ventilation can create a more pleasant and energy-efficient environment within the station. The design should incorporate large windows, skylights, and open spaces to allow for ample daylight and fresh air circulation. 6. Acoustic Considerations: Railway stations can be noisy environments due to the constant movement of trains and passengers. The design should incorporate sound-absorbing materials, proper insulation, and strategic placement of barriers to reduce noise levels and create a more comfortable atmosphere. 7. Aesthetic Appeal: Steel railway stations should also be visually appealing, blending seamlessly with the surrounding environment or showcasing unique architectural features. The design should consider the station's role as a landmark and a gateway, creating a positive impression on passengers and the community. 8. Maintenance and Durability: Steel structures require regular maintenance to ensure their longevity. The design should consider easy access for maintenance workers and incorporate materials that are resistant to corrosion, wear and tear, and other forms of damage. By considering these design considerations, steel railway stations can be created to provide safe, efficient, and aesthetically pleasing spaces for passengers while ensuring the durability and functionality of the infrastructure.

- Q: What is the role of steel canopies in a residential structure?

- The role of steel canopies in a residential structure is to provide protection and shelter from the elements, such as rain or sun, while also adding aesthetic value to the overall design. They serve as a functional and decorative element, enhancing the outdoor space and providing shade and cover for entryways, patios, or outdoor living areas. Additionally, steel canopies offer durability and strength, ensuring long-lasting protection and support for the structure.

- Q: How do steel structures provide resistance against seismic pounding?

- Seismic pounding is effectively prevented by steel structures through various mechanisms. To begin with, the design of steel structures incorporates flexible connections between different components. These connections allow for slight movements and flexibility during an earthquake, enabling the absorption and dissipation of seismic energy. Consequently, excessive forces are not transferred between adjacent structural elements, reducing the likelihood of pounding. In addition, dampers and energy dissipation devices are frequently installed in steel structures. Strategically placed within the structure, these devices absorb and dissipate seismic energy, functioning as shock absorbers. As a result, the overall forces transmitted to the structure are minimized, thereby decreasing the potential for pounding. Another factor in preventing pounding is the careful design of clearances and gaps between adjacent elements in steel structures. These clearances provide the necessary space for relative movement between components during an earthquake, effectively preventing direct contact and the resulting pounding. Moreover, base isolation techniques are commonly employed in steel structures. This technique involves placing the structure on flexible bearings or isolators, significantly reducing the transmission of seismic forces to the building. By isolating the structure from ground motion, the potential for pounding is greatly diminished. Lastly, steel structures are designed to possess ductility, meaning they can undergo substantial deformations without failure. This ductility allows the structure to absorb and redistribute seismic energy, preventing the concentration of forces that could lead to pounding. In conclusion, the combined use of flexible connections, energy dissipation devices, appropriate clearances, base isolation, and ductility in steel structures ensures their resistance to seismic pounding. These design features work together to minimize the risk of structural damage and ensure the safety of occupants during earthquakes.

- Q: How are steel structures designed to resist blast or impact loads?

- Steel structures are designed to resist blast or impact loads through several measures. Firstly, the structural system is designed to absorb and dissipate the energy generated during a blast or impact event. This is achieved through the use of ductile materials, such as steel, which can deform without collapsing. Additionally, the structure is designed with redundancy and robustness, ensuring that even if one element fails, the overall structure remains stable. Blast-resistant components, such as blast-resistant windows and doors, are also incorporated to mitigate the effects of an explosion. Furthermore, the structural connections are designed to be strong and rigid to prevent any progressive collapse. Overall, these design principles ensure that steel structures can effectively withstand blast or impact loads, protecting occupants and minimizing damage.

- Q: What are the key considerations in the design of steel structures for residential buildings?

- When it comes to designing steel structures for residential buildings, there are several important factors that must be taken into account. These factors include: 1. Structural Integrity: It is crucial to design steel structures that can withstand the various loads and forces they will be subjected to, such as gravity, wind, and seismic forces. The structural design should ensure the stability of the building and its ability to safely support its own weight, as well as any additional loads. 2. Safety: The safety of the occupants is of utmost importance in residential buildings. Therefore, steel structures should be designed in compliance with the necessary safety standards and codes, including fire resistance requirements. It is essential to incorporate fire protection measures into the design, such as the use of fire-rated materials and appropriate fire suppression systems. 3. Durability: Residential buildings are expected to have a long lifespan, so the steel structure should be designed to be durable and resistant to corrosion. This can be achieved through the application of corrosion-resistant coatings and the implementation of proper maintenance practices. 4. Aesthetics: The design of steel structures in residential buildings should also take into consideration the visual appeal of the building. The appearance of the steel elements can be customized to complement the overall architectural design of the building and enhance its aesthetic appeal. 5. Cost-effectiveness: The cost of the steel structure is an important consideration in residential building design. Therefore, the design should aim to optimize the use of steel materials while still meeting the required strength and safety standards. This can help minimize material costs and construction time. 6. Flexibility: Residential buildings often require flexibility in terms of interior layouts and the potential for future modifications. The design of steel structures should allow for easy reconfiguration or expansion without compromising the integrity of the building. 7. Sustainability: With increasing concerns about environmental impact, the design of steel structures for residential buildings should incorporate sustainable practices. This can include the use of recycled steel and the integration of energy-efficient design elements, such as insulation and efficient HVAC systems. In summary, the design of steel structures for residential buildings revolves around ensuring structural integrity, safety, durability, aesthetics, cost-effectiveness, flexibility, and sustainability. By addressing these considerations, designers can create steel structures that meet the functional and aesthetic requirements of residential buildings while ensuring the safety and comfort of their occupants.

- Q: How do steel structures contribute to the overall aesthetics of a building?

- Steel structures can contribute to the overall aesthetics of a building in several ways. Firstly, steel allows for the creation of unique and intricate architectural designs that may not be achievable with other materials. Its high strength-to-weight ratio allows for the creation of large, open spaces and long spans, giving architects more freedom to design buildings with striking visual elements. Additionally, steel structures can be easily manipulated and shaped, allowing for the creation of complex and visually appealing forms. Whether it is a curvilinear shape or a sleek and modern design, steel structures can be fabricated to meet the specific aesthetic requirements of a building. Moreover, steel structures often have a clean and polished appearance. The smooth surfaces and precise lines of steel beams and columns can create a sleek and contemporary look, adding a sense of elegance and sophistication to a building's overall design. Furthermore, the use of steel in construction allows for the incorporation of large windows and glass facades. Steel frames provide the necessary strength to support the weight of the glass panels, allowing for expansive views, natural light, and a sense of transparency. This combination of steel and glass can create a visually stunning effect, making the building appear more open, bright, and connected to its surroundings. Lastly, steel structures can also contribute to the overall aesthetic appeal of a building through their versatility and adaptability. Steel can be easily modified and extended, allowing for future additions or alterations to the building's design. This flexibility ensures that the building can evolve with changing needs and trends while maintaining its visual integrity. In conclusion, steel structures offer numerous benefits to the overall aesthetics of a building. From enabling unique and intricate designs to providing a clean and polished appearance, steel contributes to the creation of visually appealing and architecturally striking buildings.

- Q: What are the different types of steel members used in structures?

- There are several different types of steel members used in structures, including beams, columns, trusses, and plates. Beams are horizontal members that support loads by resisting bending, while columns are vertical members that provide structural support and stability. Trusses are composed of interconnected members that form triangular shapes and are used to support roofs, bridges, and other structures. Plates are flat steel members used for various purposes, such as floor and wall panels, as well as in the construction of tanks and vessels. These different types of steel members play crucial roles in providing strength and stability to structures.

- Q: How are steel structures designed for educational institutions such as schools and universities?

- Steel structures for educational institutions such as schools and universities are typically designed using a combination of architectural, structural engineering, and safety considerations. The design process involves assessing the specific requirements and objectives of the educational institution, including factors like space utilization, functionality, aesthetics, and sustainability. Structural engineers analyze the load-bearing capacity, seismic performance, and other structural aspects to ensure the safety and stability of the steel structure. Additionally, considerations are made for future expansion, energy efficiency, and cost-effectiveness. The ultimate goal is to create a durable, flexible, and conducive learning environment that meets the unique needs of the educational institution.

- Q: What are the environmental implications of using steel in construction?

- The environmental implications of using steel in construction are twofold. On the positive side, steel is an incredibly durable and strong material that allows for the construction of long-lasting and secure structures. This durability reduces the need for frequent repairs or replacements, thereby lessening the overall environmental impact. Furthermore, steel is highly recyclable, with a global recycling rate of approximately 90%. This means that steel used in construction can be easily repurposed and recycled at the end of a building's life, reducing the demand for new steel production and the associated environmental impact of mining and extraction. However, there are also negative environmental implications to consider when utilizing steel. The production of steel involves significant energy consumption and carbon emissions. The primary method of steel production, known as the Basic Oxygen Furnace (BOF) process, requires large quantities of coal and releases substantial amounts of carbon dioxide into the atmosphere. This contributes to greenhouse gas emissions and climate change. Moreover, the extraction of iron ore, which is the primary raw material for steel, can also have environmental consequences. If not properly managed, mining activities can lead to deforestation, habitat destruction, soil erosion, and water pollution. To address these environmental implications, the steel industry has been striving to reduce its carbon footprint through the adoption of cleaner technologies and practices. By using electric arc furnaces (EAFs) instead of BOF processes, carbon emissions can be significantly reduced. Additionally, the industry has been exploring alternative methods for iron ore extraction that are less harmful to the environment. Furthermore, the recycling of steel plays a crucial role in reducing the environmental impact of steel production. By increasing the recycling rate and promoting the use of recycled steel in construction, the demand for new steel can be decreased, resulting in energy and resource savings. In conclusion, the use of steel in construction has both positive and negative environmental implications. While steel is durable and highly recyclable, its production and extraction processes contribute to carbon emissions and environmental degradation. To minimize these implications, the industry should focus on adopting cleaner technologies, increasing recycling rates, and promoting sustainable practices throughout the steel supply chain.

1. Manufacturer Overview

| Location | SHANDONG,China |

| Year Established | 2008 |

| Annual Output Value | Above US$20 Billion |

| Main Markets | WEST AFRICA,INDIA,JAPAN,AMERICA |

| Company Certifications | ISO9001:2008;ISO14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | TIANJIN PORT/ QINGDAO PORT |

| Export Percentage | 0.6 |

| No.of Employees in Trade Department | 3400 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average, High |

Send your message to us

Heavy steel Workshop

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 sqare meters m.t.

- Supply Capability:

- 50000 Square Meters/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords