Customized 1.2-7.0mm patterned aluminum sheet for anti-skid use in automobiles/ships 5052 5083 3003

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Anti-skid patterned aluminum sheet is a product with concave and convex patterns on the surface of the aluminum sheet, which has anti-skid function. Our company produces anti-skid aluminum sheets. Common patterned aluminum sheets in the market include five-rib, three-rib, one-rib, diamond-patterned anti-skid aluminum sheets, which are suitable for anti-skid use in various vehicles, containers, stairs, ship deck anti-skid equipment and other buildings.

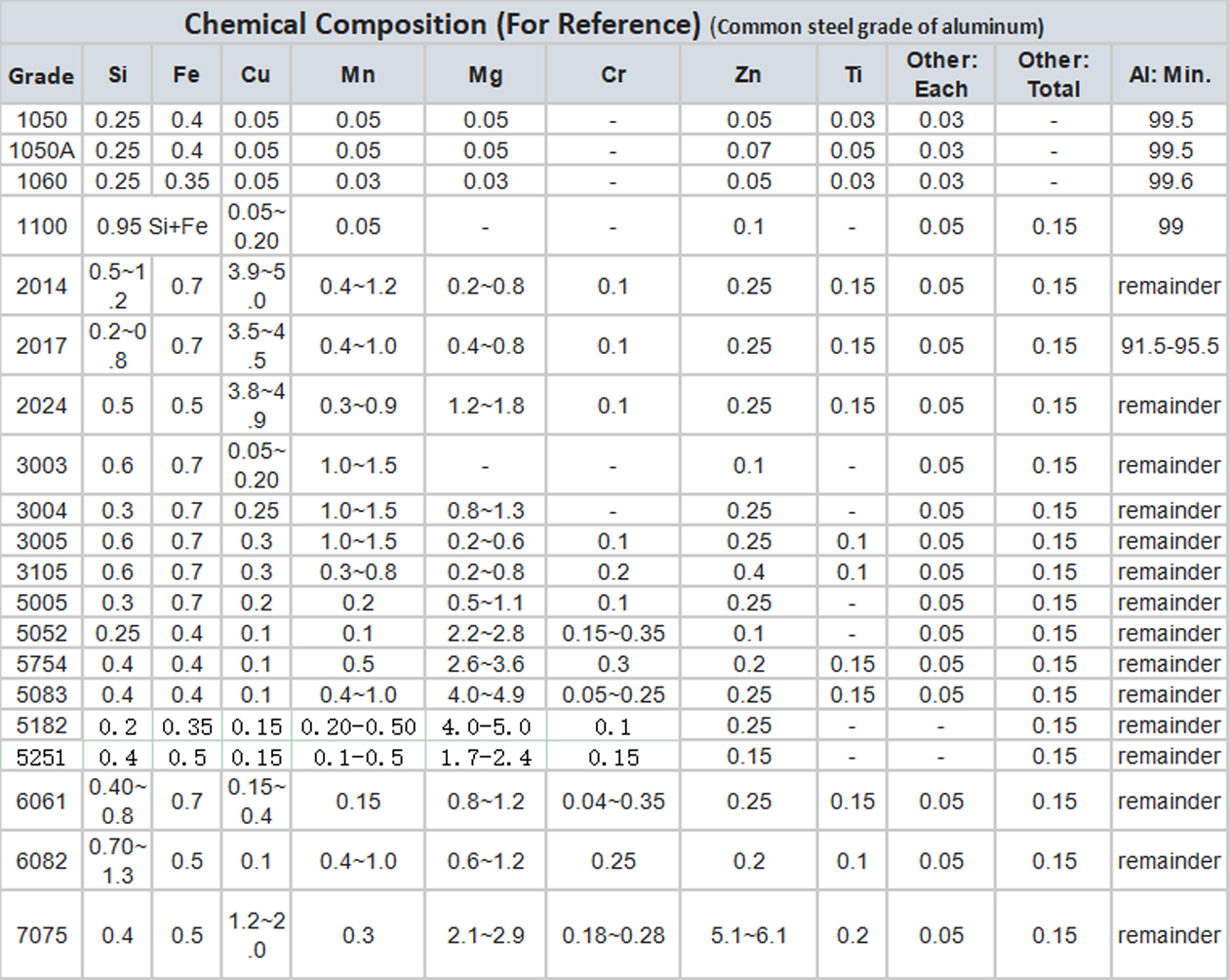

The main products of patterned aluminum sheets are 1xxx series, 3xxx series, 5xxx series, and 6xxx series aluminum alloy sheets. The product surface is clean, shiny, without burrs, black wire, etc. The product models are complete and can be customized according to customer needs and exported overseas.

Specifications of anti-slip patterned aluminum sheets:

| Alloy | 5000 series: 5052 5754 5083 5086 6000 series: 6061 6063 6082 3000 series: 3003 3004 3005 3105 1000 series: 1050 1060 1100 |

| Temper | O H12/H22 H14/H24, H16, H18, H114 H194, T6 T4, etc. |

| Thickness | 0.7-10.0mm |

| Width | 20-2100mm |

| Length | 1000mm, 2000mm, 2440mm, 3000mm, 3048mm, 6000mm, or as required |

| Embossed pattern | small 5bar, large 5bar, 3bar, 2bar, 1bar, diamond, propeller, pointer, etc. |

| Advantages | 1. Accurate size, good anti-slip effect, wide range of applications 2. Strong plasticity, easy to form, excellent processing performance. 3. Embossed aluminum sheet can form a dense and solid oxide film on the aluminum surface to prevent the intrusion of oxygen, so it has good corrosion resistance. 4. Good elongation and tensile strength, can fully meet normal processing requirements (stamping, stretching), high formability. 5. The surface quality of the patterned sheet is good, without oil spots, waves, scratches, roller marks, neat cutting edges, and no burrs. |

| Application | Floors of aircraft, light rail, and vehicles; decks, stairs, ladders, racks, temporary scaffolding, platforms, cantilever beams, elevators, etc. of ships. |

| Samples | Free samples |

| MOQ | 1 tons |

Advantages of anti-slip patterned aluminum sheet:

1. Excellent anti-slip performance, widely used

2. High hardness surface, strong wear resistance, long service life

3. Corrosion resistance

4. Lightweight, easy to install

5. Beautiful appearance

- Q: why could aluminum pot be repaired by knocking the aluminum sheet into the pot but not being bonded by glue?

- the oxidation rate of aluminum's surface is very quick, so we cann't use the method of tin welding, and the cost of argon arc welding is very high,so aluminum pot's repair usually uses riveting. aluminum has low hardness and good ductility, so it can be repaired by tightly knocking, without the bonding of glue. general glue will decomposed in open fire, if we bond pot by glue, the pot after repair won't be able to endure high temperature.

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: Can aluminum sheets be used for food processing conveyors?

- Yes, aluminum sheets can be used for food processing conveyors. Aluminum is a popular choice for food processing equipment due to its many desirable properties. It is lightweight, corrosion-resistant, and has excellent thermal conductivity. These features make aluminum sheets ideal for use in food processing conveyors, as they can withstand the demanding environment of food production while ensuring efficient and safe transportation of food products. Additionally, aluminum is easy to clean and maintain, making it a hygienic choice for food processing applications.

- Q: I'm trying a new brownie recipe for the holidays this year. My experiences with baking brownies is never good. After I've taken them out of the oven and let them cool, I can never get them out of the pan without them falling apart on me! Can I bake brownies in the pan if it's lined with aluminum foil? I think that may make them easier to get out. Also, the new recipe I'm trying is actually a cheater recipe that starts with devils food cake mix. These are going to be gifts for friends and coworkers, and I just want perfectly squared, clean brownies! Any tips or ideas?

- You can do that with the foil and when the brownies are removed from the pan you will have saved yourself a clean up. Just throw out the foil. You can also spray the pan with PAM and then you will have to clean the pan afterwards.

- Q: I need to install hand rails around a hot tub and wonder if aluminum would work well.

- Bad idea, it will corrode. Better are pool rails made from steel and powder coated in white, or light, not chromed, so you don't get burned. You're welcome!!

- Q: Are aluminum sheets easy to clean and maintain?

- Aluminum sheets prove to be fairly effortless to clean and upkeep. Due to its innate resistance to corrosion and rust, aluminum stands as a material requiring minimal maintenance. When it comes to cleaning aluminum sheets, a gentle soap and water solution, combined with a soft cloth or sponge, will suffice. It is advisable to refrain from utilizing abrasive cleansers or scrub brushes, as they possess the potential to mar the surface. Furthermore, it is imperative to thoroughly dry the aluminum sheets following cleaning in order to prevent the occurrence of water spots or stains. Routine maintenance entails promptly wiping away any spills or stains and periodically administering a protective coating to enhance its durability. All in all, aluminum sheets present themselves as a convenient option for individuals in search of a material that is both easy to clean and maintain.

- Q: Is the value of specific heat capacity of aluminium higher or lower than the standard value? Why?

- This is not my expertise. As I have been researching this the past hour to re-educate myself, no one else has answered you. So, I will attempt to get you in the right direction by what I found. I found two specific heat values for Aluminum. The recent one is from wikipedia with the other an old text someone quoted. The specific heat of aluminum, cAl, is 0.897J g?1 K?1; this is, 0.214cal g?1 °C?1. [per wikipedia] AND The specific heat capacity of aluminum as 0.215 kcal/(kg C) [The Handbook of Chemistry and Physics, p. D-217, 1979]. Standard Value was the harder item. I found it is referred to as Hro [Where the o is a circle]. I could only find it referring to water. To measure heat for each metal, it was always compared to the heating water, which is used as the standard. I'm guessing its like a thermometer filled with mercury. The mercury gets heated and the lines are marked to tell you how hot the air is. Hope that helps... Maybe someone else will jump in...

- Q: Can aluminum sheets be custom cut to specific sizes?

- Indeed, specific sizes can be achieved through the customization of aluminum sheets. Possessing great versatility, aluminum proves itself as a material that can be effortlessly shaped and cut to meet particular needs. By utilizing appropriate tools and equipment, one can achieve precise cuts on aluminum sheets, regardless of their purpose in industrial, commercial, or personal settings. This adaptability allows for the tailoring of aluminum sheets to suit specific applications, rendering it a favored option across various industries such as construction, automotive, and aerospace. Whether one requires compact or expansive aluminum sheets, they can be conveniently tailored to the precise dimensions necessary, guaranteeing an accurate fit for any given project or application.

- Q: What are the potential health hazards related to working with aluminum sheets?

- <p>Working with aluminum sheets generally has low health risks. However, inhalation of aluminum dust can cause respiratory issues, such as coughing and shortness of breath. Prolonged exposure may lead to a condition known as metal fume fever. Additionally, aluminum can cause skin irritation in some individuals. It's important to use proper ventilation and personal protective equipment, such as masks and gloves, to minimize these risks.</p>

- Q: What is the typical lead time for ordering aluminum sheets?

- The typical lead time for ordering aluminum sheets can vary depending on various factors such as the supplier, the quantity of sheets ordered, and the current demand for aluminum. However, in general, lead times for ordering aluminum sheets can range from a few days to several weeks. For standard-sized aluminum sheets that are readily available in stock, the lead time is usually shorter, typically ranging from a few days to a week. This is because suppliers often have these common sizes in their inventory and can ship them out quickly. On the other hand, if you require custom-sized aluminum sheets or a large quantity that is not readily available, the lead time may be longer. In such cases, the supplier may need to source the aluminum, cut it to the desired size, and process any necessary treatments or finishes. This process can take several weeks, especially if the supplier has a high volume of orders or if the aluminum needs to be imported. It is important to communicate with the supplier to determine the specific lead time for your order. They will be able to provide you with an estimated timeframe based on their current production capacity, stock availability, and any other factors that may impact the lead time.

Send your message to us

Customized 1.2-7.0mm patterned aluminum sheet for anti-skid use in automobiles/ships 5052 5083 3003

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords