High Reflectivity 3003 5052 5083 Series Mirror Aluminum Sheet Is Suitable For Lighting

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The high reflectivity of the mirror reflective aluminum sheet is determined by the special structure of its surface. The surface of the mirror reflective aluminum sheet is polished to form a very smooth mirror surface. When light shines on the surface of the aluminum sheet, reflection occurs. Due to the good conductivity of aluminum, it can quickly conduct light to the inside of the aluminum sheet, and then reflect the light inside to make it emit again. This series of reflection processes makes the mirror reflective aluminum sheet have a very high reflectivity.

Mirror anodized aluminum sheet is an aluminum coil product that has been specially processed to make the aluminum surface achieve a mirror effect. The surface of the mirror anodized aluminum sheet is as smooth as a mirror. At the same time, the oxide layer can protect the aluminum sheet itself, with high hardness, wear resistance, and excellent corrosion resistance.

Common alloys for mirror aluminum coils: 1050, 1070, 1085, 3003, 5052, 5083, 5657 and other alloys. The colors include basic colors and metallic colors. They can be customized according to customer needs and are widely used in lighting, aerospace, automobile, electronics and other industries.

Mirror aluminum coil product information:

Product:Mirror aluminum

Reflectivity:86%-95%

Typical alloy:1050 1060 1070 1100 3003 5052 5083 8011

Typical temper:O--H24

Thickness: 0.07-4.0mm

Width: 40-1600mm

Length: 1000-16000mm

ID:205mm,405mm,505mm

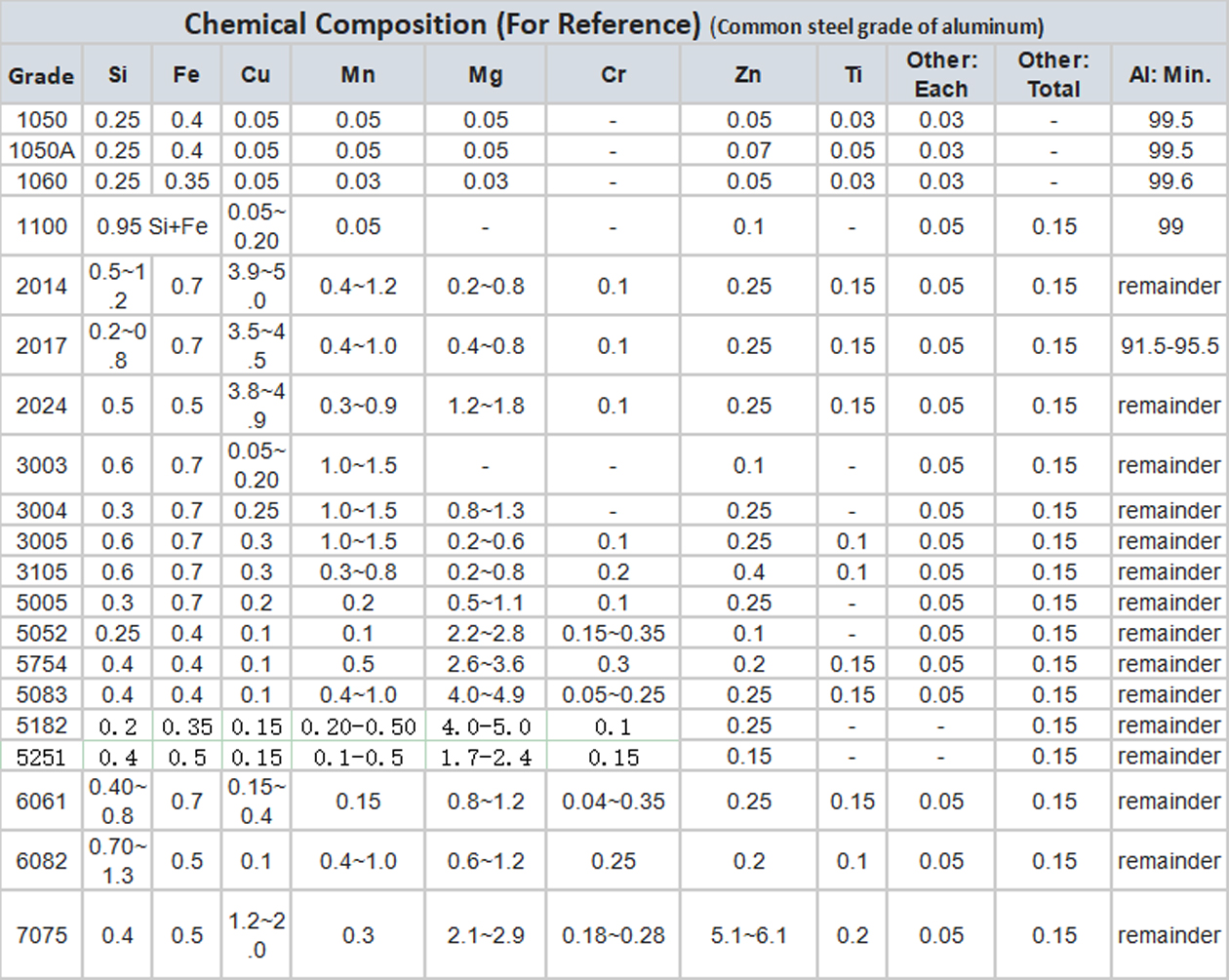

Chemical composition of aluminum plate

Mirror aluminum features:

1. High reflectivity

2. High surface finish and bright color

3. Light weight

4. High strength and not easy to scratch

5. Strong weather resistance and long service life

6. Good self-cleaning, no oil, no water, anti-pollution

7. Strong plasticity

8. Moderate price, low maintenance cost, high cost performance

9. Convenient construction and installation

10. Green and environmentally friendly

- Q: What is the modulus of elasticity for aluminum sheets?

- The modulus of elasticity for aluminum sheets, also known as Young's modulus, is typically around 69 GPa (gigapascals) or 10 million pounds per square inch (psi). This value represents the measure of the stiffness or rigidity of the material. However, it is important to note that the modulus of elasticity can vary slightly depending on the specific alloy composition and tempering of the aluminum sheet.

- Q: Are 101 aluminum sheets suitable for marine environments?

- No, 101 aluminum sheets are not suitable for marine environments as they lack sufficient corrosion resistance.

- Q: What are the different types of aluminum sheets available in the market?

- There are several different types of aluminum sheets available in the market, each with its own unique characteristics and applications. Some of the most common types include: 1. Plain Aluminum Sheet: This is the most basic and widely used type of aluminum sheet. It is known for its excellent corrosion resistance and high strength-to-weight ratio. Plain aluminum sheets are commonly used in construction, automobile manufacturing, and aerospace industries. 2. Painted Aluminum Sheet: These sheets are coated with a layer of paint to enhance their aesthetic appeal and protect the underlying aluminum from environmental elements. Painted aluminum sheets are commonly used in architectural applications, signage, and decorative purposes. 3. Perforated Aluminum Sheet: This type of aluminum sheet features perforations or holes throughout its surface. It is often used in architectural projects, industrial filtration systems, and ventilation applications. 4. Embossed Aluminum Sheet: These sheets have a textured or patterned surface, created by embossing or rolling the aluminum. Embossed aluminum sheets are frequently used for decorative purposes, such as interior design, signage, and packaging. 5. Anodized Aluminum Sheet: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum. Anodized aluminum sheets are highly resistant to corrosion and abrasion, making them suitable for outdoor applications, such as building facades and automotive parts. 6. Tread/Diamond Plate Aluminum Sheet: This type of aluminum sheet features raised diamond or tread patterns on its surface, providing enhanced grip and traction. Tread/diamond plate aluminum sheets are commonly used in transportation, flooring, and staircases. Additionally, aluminum sheets are available in various thicknesses, sizes, and alloys, such as 3003, 5052, and 6061. The specific type of aluminum sheet required depends on the intended use and specific requirements of the project.

- Q: which kind of material won't influence magnet attracting iron nail? Does copper sheet or aluminum sheet influence it?

- Copper coil will impede magnetic penetration. People separate the magnet from the workpiece of machine tool to avoid magnetic short circuit and attraction loss, making magnetic line of force go through the workpiece. An opening copper bush is added into the iron core of magnetic closing coil or opening solenoid to avoid the iron core being attracted on the external iron piece and stop operation. The opening is for avoiding eddy formulation and short circuit, iron core in copper bush is the ruled magnetic circuit.

- Q: i m not sure if aluminum hydroxide is a acid or base. if somebody could help me, i will really appreciate.If u can could you also tell me if im wrong or right about the following substances:- pepsi cola is acid- vinegar is a base- ammonia is a base- aluminum hydroxyde is ?thank u for your help.

- as stated anything ending in -OH is a base, therefore AlOH is a base. the others are correct except for vinegar, it is an acid, not a base.

- Q: Is it possible to use aluminum sheets for creating roofing tiles?

- <p>Yes, you can use aluminum sheets to make roofing tiles. Aluminum is a popular material for roofing due to its durability, lightweight, and resistance to corrosion. It can be shaped into various styles and sizes to mimic traditional roofing materials like clay or slate. Aluminum roofing tiles are also known for their energy efficiency, as they reflect heat and can help reduce cooling costs. However, it's important to ensure that the aluminum sheets are of good quality and installed correctly to achieve the desired performance and longevity.</p>

- Q: Can 101 aluminum sheets be painted or coated?

- Yes, 101 aluminum sheets can be painted or coated.

- Q: What are the distinctions among various grades of aluminum sheets?

- <p>Yes, there are differences between different grades of aluminum sheets. These differences are primarily based on the alloy composition, which affects properties such as strength, formability, and corrosion resistance. For instance, 1000 series aluminum is pure and soft, making it ideal for general purposes. 2000 series is harder and stronger, often used in aerospace applications. 3000 series is known for its high resistance to corrosion and is used in marine applications. 5000 series offers good strength-to-weight ratio and is used in structural applications. 6000 series is known for its strength and is used in construction and industrial applications. Each grade has specific uses based on its unique characteristics.</p>

- Q: Is it possible to use aluminum sheets in extreme weather conditions, including very hot and very cold temperatures?

- <p>Yes, aluminum sheets can be used in harsh environments, including hot and cold climates. Aluminum is known for its excellent corrosion resistance and durability, making it suitable for various weather conditions. It does not rust and maintains its strength in both low and high temperatures. However, it's important to consider the specific alloy and protective coatings used, as these can affect performance in extreme conditions. Properly treated and coated aluminum can withstand significant temperature fluctuations without significant degradation.</p>

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets possess remarkable properties when it comes to resisting weather. Their innate ability to resist corrosion enables them to endure exposure to various weather conditions without deteriorating or rusting, making them highly suitable for outdoor uses. The natural formation of a protective oxide layer on the surface of aluminum acts as a barrier against moisture, preventing the metal from reacting with oxygen and thereby reducing the risk of corrosion. Moreover, aluminum sheets exhibit a high resistance to UV radiation, which means they can withstand prolonged exposure to the sun without fading or discoloration. In conclusion, aluminum sheets exhibit outstanding weather resistance and are a dependable choice for a wide range of outdoor applications, such as roofing, siding, and outdoor signage.

Send your message to us

High Reflectivity 3003 5052 5083 Series Mirror Aluminum Sheet Is Suitable For Lighting

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords