High Class Steel-Work made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

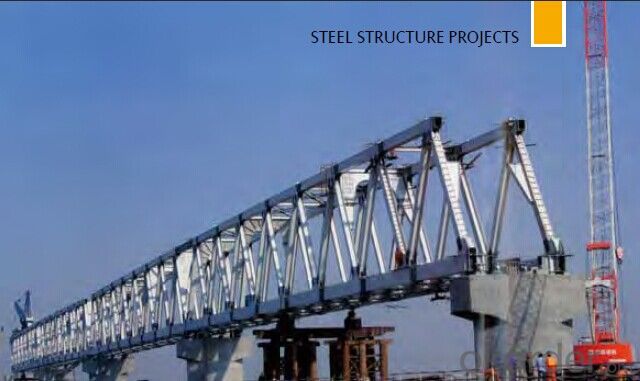

Project Reference:

Area: 17,000m2

Steel Structure Quantity: 2,700ton

Color-Steel Plate Area: 29,670ton

Column Height: 32m

Weight of Per Column: 25ton

Crane Tonnage: 300ton

Total Cost: 25,080,000RMB

Duration: 150days

- Q: What are the advantages of using steel structures in the mining industry?

- There are several advantages of using steel structures in the mining industry. Firstly, steel structures are highly durable and can withstand extreme weather conditions, seismic activities, and heavy loads. This durability ensures the safety and longevity of mining infrastructure. Secondly, steel structures are cost-effective in the long run. They require minimal maintenance and have a longer lifespan compared to other construction materials. This reduces the need for frequent repairs and replacements, resulting in considerable cost savings for mining companies. Additionally, steel structures provide flexibility in design and construction. They can be easily modified, expanded, or relocated as per the changing needs of the mining operation. This adaptability allows for efficient utilization of resources and streamlines the construction process. Moreover, steel structures offer superior fire resistance, which is crucial in the mining industry where the risk of fire accidents is high due to various factors like flammable materials and equipment. Steel's inherent fire-resistant properties make it a reliable choice for ensuring the safety of miners and protecting valuable assets. Lastly, steel structures are environmentally friendly. Steel is a highly recyclable material, and using steel structures in mining operations promotes sustainable practices. It reduces the need for new raw materials and minimizes waste generation, contributing to a greener and more sustainable mining industry.

- Q: How are steel structures designed for power plants?

- Steel structures for power plants are designed with several key considerations in mind. Firstly, the structural design must be able to support the heavy equipment and machinery used in power generation, such as turbines, boilers, and generators. These components can be extremely large and require strong and stable foundations. Another important aspect of the design is to ensure the steel structure can withstand the various loads and forces that are present in power plants. These can include static loads such as the weight of the equipment, as well as dynamic loads such as vibrations and seismic forces. The structure must be able to resist these loads and provide a safe and stable environment for the operation of the power plant. Additionally, steel structures for power plants need to consider factors such as thermal expansion and contraction. The equipment used in power generation produces high temperatures, which can cause the steel structure to expand and contract. The design must account for these movements to prevent any structural damage or failure. Fire safety is another critical aspect of the design. Power plants contain flammable materials and the potential for fires. Steel structures are designed to be fire-resistant, with proper fireproofing materials and insulation to prevent the spread of fire and ensure the safety of personnel and equipment. Lastly, the design of steel structures in power plants also considers factors such as accessibility for maintenance and repairs. Power plants require regular inspections, maintenance, and possible equipment replacements. The design should provide easy access to different areas of the structure to facilitate these activities, ensuring the longevity and efficiency of the power plant. In summary, steel structures for power plants are designed to support heavy equipment, resist various loads and forces, account for thermal expansion and contraction, provide fire safety, and allow for easy maintenance and repairs. These considerations ensure the safe and efficient operation of power plants.

- Q: How are steel structures designed to resist snow and ice accumulation?

- Steel structures are designed to resist snow and ice accumulation through various methods. These include increasing the structural load capacity to account for the added weight of snow and ice, designing the roof with a slope to allow for snow and ice to slide off, and incorporating features like gutters and heating systems to prevent ice formation. Additionally, engineers consider local climate conditions and snow load requirements to ensure the structural integrity and safety of steel buildings in areas prone to heavy snowfall.

- Q: What are the considerations for designing steel roof trusses?

- When designing steel roof trusses, there are several key considerations to take into account. These include the load-bearing capacity of the trusses, the span of the roof, the pitch or slope of the roof, the desired aesthetic appearance, the local building codes and regulations, the available budget, and the environmental conditions the roof will be subjected to, such as wind and snow loads. Additionally, factors like the type of steel used, the connections between the truss members, and any additional features like insulation or ventilation must also be considered. By carefully addressing these considerations, a well-designed and structurally sound steel roof truss system can be created.

- Q: How are steel structures designed to be resistant to corrosion in industrial settings?

- Steel structures in industrial settings are designed to be resistant to corrosion through several methods. One common approach is to apply protective coatings, such as paint or specialized anti-corrosion coatings, that act as a barrier between the steel and the environment. Additionally, galvanization, which involves coating the steel with a layer of zinc, can provide enhanced corrosion resistance. Regular maintenance, including inspections and repairs of any damaged coatings, is also crucial to ensuring long-term corrosion resistance.

- Q: How are steel structures designed to be resistant to electromagnetic interference?

- There are several ways to design steel structures to resist electromagnetic interference (EMI). The first method involves using steel as the primary construction material, which naturally shields against electromagnetic waves due to its high electrical conductivity. This allows steel to effectively absorb and dissipate electromagnetic energy. To further enhance EMI resistance, additional strategies can be implemented during the design and construction phases. One common approach is to create a Faraday cage effect by enclosing sensitive equipment or areas within steel structures. This involves using conductive material to block external electromagnetic fields from entering the protected space. Another important aspect is designing steel structures with proper grounding systems. These systems ensure that any electromagnetic energy induced or conducted within the structure is directed and dissipated safely to the earth. This minimizes the impact on sensitive electronic devices. The layout and placement of electrical and communication cables within steel structures also require careful consideration. Shielding or routing these cables away from potential sources of electromagnetic interference can reduce the risk of signal degradation or disruption. In addition to these design measures, it is necessary to periodically test and maintain the electromagnetic shielding effectiveness of the steel structure. This involves using specialized equipment to measure its effectiveness and identify areas for improvement. Overall, by utilizing steel as a construction material, implementing appropriate shielding techniques, and maintaining proper grounding systems and cable routing, steel structures can be designed to resist electromagnetic interference and provide a secure and dependable environment for sensitive electronic equipment.

- Q: How are steel structures used in the construction of transportation terminals?

- Steel structures are commonly used in the construction of transportation terminals due to their strength, durability, and versatility. Steel beams and columns provide the structural framework, supporting the weight of the terminal and allowing for large open spaces. Steel can also be easily fabricated and installed, making it efficient for fast-track construction projects. Additionally, steel structures can withstand heavy loads and extreme weather conditions, ensuring the safety and longevity of transportation terminals.

- Q: What is the purpose of steel beams in a structure?

- Steel beams serve the purpose of providing strength, support, and stability to the overall construction of a structure. Renowned for their exceptional load-bearing capacity, steel beams are ideal for withstanding heavy loads and safely transferring them to the foundation or other load-bearing elements. Various types of buildings, including skyscrapers, bridges, warehouses, and residential homes, commonly utilize steel beams as essential structural components. These beams often form the skeleton or framework of the building, ensuring stability and integrity by evenly distributing weight and stress. This prevents the structure from collapsing or deforming under its own weight or external forces like wind, earthquakes, or snow loads. Additionally, steel beams offer flexibility in design and construction. With their high strength-to-weight ratio, they can span longer distances without the need for additional support columns or walls, allowing for open and spacious interior layouts. This versatility empowers architects and engineers to create innovative designs and maximize usable space. Beyond their structural role, steel beams also contribute to the fire resistance of the building. Steel, being a non-combustible material with a high melting point, exhibits excellent resistance to fire. Properly coated or protected, steel beams can maintain their structural integrity even in high-temperature environments. This provides valuable time for occupants to evacuate and firefighters to control the fire. In summary, the purpose of steel beams in a structure is to ensure the safety, stability, and longevity of the building while also allowing for efficient and flexible design possibilities.

- Q: What are the common design considerations for steel structures in educational facilities?

- Some common design considerations for steel structures in educational facilities include the need for flexibility and adaptability to accommodate changing educational needs, the requirement for large open spaces to facilitate various activities, the consideration of safety and durability to withstand heavy usage and potential natural disasters, the integration of natural lighting and ventilation for a conducive learning environment, and the incorporation of sustainable and energy-efficient features to reduce environmental impact and operating costs.

- Q: What is the role of steel in soundproofing and acoustics?

- Due to its unique properties, steel plays a vital role in soundproofing and acoustics. Its high mass and density make it an effective barrier against sound transmission. When used in walls or panels, steel blocks and absorbs sound waves, preventing them from traveling through the structure. Additionally, its density helps reduce vibrations and resonance, which are major contributors to noise. Steel's rigidity makes it ideal for constructing structures with minimal sound transmission. By using steel studs, beams, or frames, buildings can have improved sound isolation and reduced noise pollution. Its strength and durability ensure the effectiveness of soundproofing measures over time. Not only does steel block sound, but it can also enhance acoustic performance. Perforated steel panels are commonly used in theaters, concert halls, and recording studios to control reverberation and improve sound quality. These panels have small holes that allow sound to pass through while trapping and dissipating excessive sound energy, reducing echoes and enhancing clarity. Moreover, steel can be combined with other sound-absorbing materials, like mineral wool or foam, to create composite panels or insulation. These materials absorb sound energy, while steel provides structural integrity and fire resistance. This combination allows for effective noise reduction in various applications, including industrial facilities, offices, and residential buildings. In conclusion, steel's density, rigidity, and compatibility with sound-absorbing materials make it an essential component in soundproofing and acoustics. Whether used as a barrier or in the design of acoustic features, steel significantly contributes to creating quieter and more acoustically pleasing environments.

Send your message to us

High Class Steel-Work made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches