steel structure workshop warehouse building design, manufacture and installation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Parameters

Item Name | steel structure workshop warehouse building |

Main Material | Q235/Q345 Welded H Beam and Hot Rolled Section Steel |

Surface | Painted or Hot Dip Galvanized |

Roof & Wall Panel | EPS Sandwich panel /Single Corrugated Steel Sheet/ Colour sheet with Glass-wool, for customers choose |

Window | PVC Steel or Aluminum Alloy |

Door | Sliding Door or Rolling Up Door |

Service | Design, Fabrication and Installation |

We can make quotation according to customer's drawing or requirement; (size by length/width/height and wind speed), offering a free design drawing and all detailed drawings for installation. | |

Design software: Auto CAD,PKPM,MTS,3D3S, Tarch, Tekla Structures(Xsteel)V12.0.etc | |

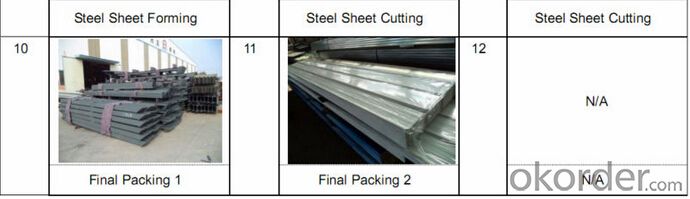

Packing | According to customer's requirement |

Load into 40/20GP,40HQ or 40OT |

- Q: What are the different types of steel reinforcement used in structures?

- There are several types of steel reinforcement commonly used in structures, including mild steel bars, deformed steel bars, welded wire fabric, and prestressed steel strands.

- Q: How are steel structures designed for educational campuses and institutions?

- Steel structures for educational campuses and institutions are typically designed with careful consideration of various factors such as the intended use, aesthetics, durability, and sustainability. Architects and engineers collaborate to create efficient and versatile designs that meet the specific requirements of the campus or institution. These structures often incorporate open and flexible spaces that can be easily adapted for different purposes, such as classrooms, laboratories, auditoriums, and libraries. Additionally, steel structures offer advantages such as quick construction, cost-effectiveness, and the ability to withstand extreme weather conditions, making them a popular choice for educational facilities.

- Q: How are steel structures designed for seismic zones?

- Steel structures designed for seismic zones are constructed to endure the immense forces generated during an earthquake. These structures are specifically engineered to minimize the potential damage caused by seismic activity and ensure the safety of the individuals inside. The design procedure for steel structures in seismic zones entails several crucial factors. First and foremost, the selection of suitable materials is of utmost importance. Typically, high-strength steel with excellent ductility is used as it is capable of effectively absorbing and dissipating seismic energy. The steel components are also designed to possess adequate stiffness and flexibility in order to resist lateral forces and deform under seismic loads. Another significant aspect is the structural arrangement. Buildings in seismic zones are frequently designed with lateral load-resisting systems, such as moment frames, braced frames, or shear walls. These systems provide stability and distribute seismic forces throughout the structure, thereby reducing the concentration of stress on specific elements. Furthermore, the connections between steel members are meticulously designed to ensure their ability to withstand seismic forces. Special attention is given to the detailing of connections to guarantee that they possess sufficient strength, ductility, and energy dissipation capacity. Properly designed connections can enhance the overall performance of the steel structure during an earthquake. In addition to material selection and structural arrangement, engineers also take into account the site-specific conditions and ground motion characteristics. Seismic hazard assessments are conducted to determine the expected level of ground shaking in a particular area. This information aids in establishing the design parameters and ensuring that the steel structure can safely withstand the anticipated seismic forces. Computer simulations and advanced analysis techniques, such as nonlinear dynamic analysis, are frequently employed to evaluate the behavior of steel structures under seismic loads. These tools enable engineers to assess the performance of the structure, identify potential vulnerabilities, and make necessary design modifications to enhance its seismic resistance. In summary, the design of steel structures for seismic zones is a complex process that requires a thorough comprehension of the seismic forces and their impacts. By incorporating suitable materials, structural arrangements, connection designs, and site-specific considerations, engineers can create steel structures capable of enduring seismic events and safeguarding lives and property.

- Q: What is the purpose of steel columns in structures?

- The purpose of utilizing steel columns in structures is to offer vertical support and maintain structural stability. These columns are indispensable constituents that endure the weight of the structure and transmit it to the foundation. Their design is tailored to withstand compressive forces, ensuring the overall structural integrity of the edifice. Steel, as a robust and long-lasting material, permits the incorporation of tall, slender columns, thus optimizing the usable space within the structure. Moreover, steel columns exhibit exceptional resistance to fire and other external factors, rendering them a dependable choice in terms of safety. In essence, steel columns assume a pivotal role in conferring strength, stability, and durability to diverse varieties of structures, encompassing buildings, bridges, and industrial facilities.

- Q: What are the different types of steel warehouses?

- Different needs and requirements are met by various types of steel warehouses. 1. Single-Slope Warehouse: This warehouse type features a sloping roof and is primarily used for storage purposes. It offers maximum storage space at a cost-effective price. 2. Multi-Span Warehouse: Comprising multiple sections or spans separated by columns or frames, this warehouse allows for flexible layout and accommodates diverse storage needs. It is commonly utilized for large-scale industrial storage or distribution centers. 3. Clear Span Warehouse: This warehouse design boasts a spacious uninterrupted area without internal columns or supports. It provides maximum storage capacity and layout flexibility, making it ideal for large-scale manufacturing and storage operations. 4. Cold Storage Warehouse: Designed to maintain specific temperature and humidity levels, cold storage warehouses are equipped with specialized insulation, refrigeration systems, and temperature control mechanisms. They are employed for storing perishable goods like food or pharmaceuticals. 5. Mezzanine Warehouse: A two-story structure with a second floor known as a mezzanine, this warehouse type offers additional storage or office space. It suits businesses requiring both storage and office facilities within the same building. 6. Retail Warehouse: Retail warehouses are designed to store and distribute goods for retail purposes. They often incorporate office space, showrooms, and loading docks to facilitate the movement of goods from the warehouse to retail stores. 7. Automated Warehouse: Employing advanced technologies such as robotics and automated storage and retrieval systems (ASRS), automated warehouses streamline operations and increase efficiency. These warehouses minimize human intervention and maximize productivity. 8. Distribution Center: Acting as central hubs for receiving, storing, and distributing goods, distribution centers are large-scale warehouses. Equipped with specialized systems like conveyor belts and sorting mechanisms, they efficiently handle high volumes of inventory. Overall, the choice of steel warehouse design depends on factors like storage needs, industry requirements, budget, and available space. Each warehouse type offers unique advantages and is tailored to meet specific operational needs.

- Q: How are steel structures used in the construction of motels?

- Steel structures are commonly used in the construction of motels due to their high strength and durability. Steel frames provide the necessary support for the building, allowing for larger open spaces and flexible floor plans. Additionally, steel structures can withstand extreme weather conditions and are resistant to pests, reducing maintenance costs. The use of steel also allows for faster construction timelines, making it an efficient choice for motel projects.

- Q: What is the role of steel in high-rise building construction?

- The role of steel in high-rise building construction is crucial and multifaceted. Steel is widely used in the construction of high-rise buildings due to its strength, durability, and versatility. It possesses the necessary mechanical properties to withstand the immense vertical and horizontal loads experienced by tall structures. One of the primary roles of steel in high-rise construction is to provide structural support. Steel frames are commonly used to form the skeleton of the building, providing stability and strength. The high strength-to-weight ratio of steel allows the construction of tall, slender structures without excessive bulkiness. Steel columns and beams are used to transfer the weight of the building to the foundation, while steel braces and trusses help resist lateral forces such as wind and earthquakes. Additionally, steel is a highly ductile material, meaning it can bend and deform without breaking. This property is crucial in high-rise buildings as it allows the structure to absorb and dissipate energy during extreme events such as earthquakes, reducing the risk of collapse. Steel's flexibility also enables architects and engineers to design complex and innovative structures, pushing the boundaries of architectural possibilities. Furthermore, steel's fire resistance is another important factor in high-rise construction. Steel has a high melting point, making it more resistant to fire compared to other materials like wood or concrete. Additionally, steel can be protected with fire-resistant coatings, creating a barrier that slows down the spread of fire and provides valuable evacuation time. Apart from its structural role, steel is also used in various other aspects of high-rise building construction. It is commonly employed in the construction of elevators, staircases, and other components that require high load-bearing capacity. Steel's versatility allows for efficient and cost-effective prefabrication, reducing construction time and enabling faster completion of high-rise projects. In conclusion, the role of steel in high-rise building construction is vital. Its strength, durability, and versatility make it an ideal material for constructing tall structures. From providing structural support to ensuring fire resistance and enabling architectural innovation, steel plays a crucial role in ensuring the safety and success of high-rise buildings.

- Q: What are the different types of steel balconies and terraces used in buildings?

- There are several different types of steel balconies and terraces used in buildings, each with its own unique characteristics and advantages. 1. Cantilevered balconies: These balconies are supported by projecting beams or brackets that are fixed to the building structure. Cantilevered balconies provide an open and unobstructed view, as there are no supporting columns or posts. 2. Suspended balconies: Suspended balconies are attached to the building using cables or rods, giving them a floating appearance. These balconies are often seen in modern architecture and provide a sleek and contemporary look. 3. Juliet balconies: Juliet balconies are shallow balconies that are typically installed on the upper floors of buildings. They feature a protective railing or balustrade and are designed to provide a decorative element rather than a functional outdoor space. 4. Terrace gardens: Terrace gardens are larger outdoor spaces that are built on rooftops or elevated areas of a building. These terraces often have a steel structure as a base, providing stability and support for the garden above. 5. Steel railings and balustrades: In addition to balconies and terraces, steel is commonly used for railings and balustrades. These elements provide safety and aesthetic appeal, and can be customized to suit the design of the building. When selecting a steel balcony or terrace for a building, factors such as structural requirements, aesthetic preferences, and budget should be considered. It is important to consult with architects, engineers, and construction professionals to determine the most suitable type of steel balcony or terrace for a specific project.

- Q: What is the role of steel in residential buildings?

- The role of steel in residential buildings is vital and multifaceted. Steel is commonly used in the construction of residential buildings due to its exceptional strength, durability, and versatility. It offers several advantages that make it a preferred choice for builders and homeowners alike. One of the primary roles of steel in residential buildings is structural support. Steel beams and columns provide the necessary strength and stability to support the weight of the entire structure. Steel's high strength-to-weight ratio allows for the creation of larger open spaces and flexible floor plans, as it can bear heavy loads without the need for excessive supporting walls or columns. Additionally, steel is resistant to various environmental factors, including fire, earthquakes, and extreme weather conditions. It possesses excellent fire-resistant properties, making it a safe choice for residential buildings. Steel structures can also withstand seismic forces better than other construction materials, ensuring the safety of occupants during earthquakes. Moreover, steel's resistance to corrosion and decay makes it highly durable, reducing maintenance costs and increasing the lifespan of the building. Steel is also used in residential buildings for its flexibility in design. It can be easily shaped and molded into various forms, allowing architects and designers to create unique and aesthetically pleasing structures. From modern and sleek to traditional and ornate, steel can be customized to meet the desired architectural style. Furthermore, steel is a sustainable and environmentally friendly material. It is 100% recyclable, meaning that it can be reused without losing its properties or quality. This aspect promotes the conservation of natural resources and reduces the carbon footprint associated with construction. In conclusion, the role of steel in residential buildings is essential for providing structural support, ensuring safety, enabling design flexibility, and promoting sustainability. Its strength, durability, and versatility make it an ideal choice for constructing safe, aesthetically pleasing, and long-lasting homes.

- Q: How are steel structures used in the construction of retail centers and shopping complexes?

- Steel structures are commonly used in the construction of retail centers and shopping complexes due to their strength, versatility, and cost-effectiveness. Steel beams and columns provide the necessary support for large open spaces, allowing for flexible layouts and the incorporation of multiple levels. Additionally, steel's durability and resistance to fire and pests ensure the safety and longevity of these structures. Overall, steel structures offer efficient and practical solutions for creating modern, spacious, and visually appealing retail spaces.

Send your message to us

steel structure workshop warehouse building design, manufacture and installation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords