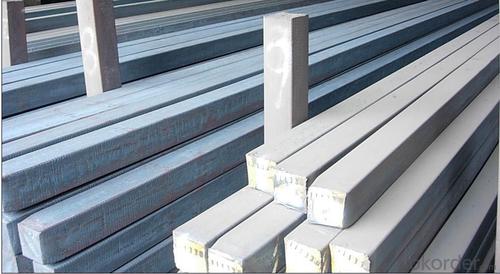

Prime square alloy steel billet 120mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 120mm Q235

Description of Prime square alloy steel billet 120mm Q235

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

Main Feature of Prime square alloy steel billet 120mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 120mm Q235

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Specifications of Prime square alloy steel billet 120mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 120mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: How do steel billets contribute to the manufacturing of machinery and equipment?

- Steel billets are a crucial raw material in the manufacturing of machinery and equipment. They serve as the starting point for various processes such as forging, rolling, and machining, where they are transformed into different components and parts. The high strength and durability of steel billets make them ideal for creating robust and reliable machinery, ensuring the final products can withstand heavy loads, harsh environments, and repetitive use. Additionally, the versatility of steel allows for the production of a wide range of machinery and equipment, from small tools to large industrial machinery, making it a vital component in the manufacturing industry.

- Q: What are the main uses of steel billets in the automotive industry?

- Steel billets are primarily used in the automotive industry for manufacturing various components such as engine parts, transmission parts, chassis, suspension systems, and body structures. These billets serve as a raw material for forging and casting processes, allowing for the production of durable and high-strength automotive components that ensure safety, performance, and longevity of vehicles.

- Q: How are steel billets used in the production of seamless pipes?

- Steel billets are an integral part of the production process for seamless pipes. Seamless pipes are pipes that are manufactured without any welding or seams, resulting in a smoother and more durable product. To produce seamless pipes, the first step is to melt steel in a furnace to create a molten metal. This molten steel is then poured into molds to form steel billets. Steel billets are solid, rectangular-shaped pieces of steel that serve as the raw material for seamless pipe production. Once the steel billets are formed, they are then heated to a specific temperature and pierced by a piercing mill. This process involves pushing a pointed mandrel through the center of the billet, creating a hollow tube or shell. The piercing mill applies both axial and radial forces to shape the billet into a seamless pipe. After piercing, the hollow tube is further elongated and reduced in diameter by a series of rolling mills. These mills use a combination of rotational and compressive forces to shape the billet into the desired seamless pipe size. The seamless pipe is continuously stretched and rolled until it reaches the desired length and diameter. The use of steel billets in the production of seamless pipes is crucial for several reasons. Firstly, the billets are made from high-quality steel, which ensures the strength and durability of the final product. Secondly, the uniformity and consistency of billets allow for precise shaping and seamless pipe dimensions. Lastly, the solid structure of billets enables them to withstand the intense forces and temperatures involved in the pipe manufacturing process. In conclusion, steel billets play a vital role in the production of seamless pipes. From being melted and molded into billets to being pierced, elongated, and rolled, these billets undergo a series of processes that transform them into high-quality seamless pipes. The use of steel billets ensures the integrity and reliability of seamless pipes, making them suitable for various industrial applications.

- Q: How do steel billets contribute to the manufacturing of furniture?

- Steel billets are an essential raw material in the manufacturing of furniture as they are used to create sturdy and durable frames, legs, and supports. The billets are melted down and shaped into various forms, allowing furniture manufacturers to produce high-quality and robust pieces that can withstand heavy loads and regular use.

- Q: How are steel billets used in the production of agricultural equipment?

- Steel billets are an essential component in the production of agricultural equipment due to their versatility and durability. These billets are semi-finished steel products that are shaped into a solid rectangular form, making them ideal for various manufacturing processes. In the production of agricultural equipment, steel billets are typically used as the raw material for forging, casting, or rolling processes. Forging involves heating the billets to a specific temperature and then shaping them into the desired form using a hammer or press. This process is commonly used to create components such as plowshares, tiller blades, and harrow teeth, which require superior strength and resistance to wear and tear. Casting is another method used in agricultural equipment production, where molten steel is poured into a mold and left to solidify. Steel billets are melted and cast into intricate shapes, allowing manufacturers to create complex components like tractor engine blocks, combine harvester parts, or even agricultural machinery frames. The ability to cast steel billets into various shapes enables the production of customized equipment that meets specific requirements. Rolling is another technique that utilizes steel billets in the production of agricultural equipment. These billets are heated and then passed through a series of rollers to reduce their size and shape them into different profiles, such as bars, rods, or sheets. Rolled steel billets are commonly used in the manufacturing of components like axles, shafts, and brackets, which are crucial for the functionality of agricultural machinery. One of the key reasons steel billets are preferred in agricultural equipment production is their inherent strength and durability. The agricultural industry demands robust machinery that can withstand harsh environments, heavy loads, and repetitive use. Steel billets offer exceptional strength, allowing manufacturers to create equipment that can endure these demanding conditions. Additionally, steel billets can be further strengthened through heat treatment processes, such as quenching and tempering, to enhance their mechanical properties. In conclusion, steel billets play a vital role in the production of agricultural equipment. Their versatility and durability enable manufacturers to create components and machinery that can withstand the challenging conditions of the agricultural industry. Whether used in forging, casting, or rolling processes, steel billets provide the necessary strength and reliability required for efficient and long-lasting agricultural equipment.

- Q: What are the different types of tests conducted on steel billets?

- Steel billets undergo various tests to assess their quality and suitability for different applications. These tests play a crucial role in determining the mechanical properties, chemical composition, and overall integrity of the billets. 1. Analyzing Chemical Composition: The chemical composition of the steel billets is examined to ensure compliance with specified standards and requirements. This analysis measures the levels of carbon, manganese, silicon, sulfur, and phosphorus, among other elements. 2. Tensile Strength Evaluation: The tensile test assesses the ability of the steel billets to withstand pulling forces without breaking. It measures parameters such as tensile strength, yield strength, and elongation. 3. Determining Hardness: The hardness test evaluates the steel billets' resistance to wear, deformation, and penetration. It involves different hardness tests such as Brinell, Rockwell, and Vickers. 4. Assessing Impact Resistance: The impact test measures the toughness and capacity of the steel billets to absorb energy under sudden loading or impact conditions. It helps determine their resistance to fracture and cracking. 5. Ultrasonic Inspection: This non-destructive test employs high-frequency sound waves to detect internal flaws or defects in the steel billets. It is a valuable method for identifying cracks, voids, and inclusions that may compromise the billets' structural integrity. 6. Verifying Dimensions: The dimensional inspection ensures that the steel billets meet the specified dimensional requirements, including length, width, and thickness. This verification confirms their suitability for intended applications and subsequent manufacturing processes. 7. Macroscopic Examination: This visual inspection involves magnified examination of the steel billets' surface and internal structure. It helps identify visible defects like cracks, porosity, segregation, or irregularities. 8. Microscopic Examination: By using a microscope, the microscopic examination analyzes the microstructure of the steel billets. It provides insights into grain size, presence of phases, and any abnormalities that may affect the steel's properties. Collectively, these tests guarantee that the steel billets meet the required quality standards and possess the necessary mechanical properties for their intended applications. They ensure the safety, reliability, and performance of steel billets in industries like construction, automotive, aerospace, and manufacturing.

- Q: What are the main factors that determine the sustainability of steel billets production?

- Several key factors determine the sustainability of steel billets production. Firstly, the choice of raw material source plays a crucial role. Utilizing recycled scrap metal as the primary raw material reduces the need for new mining and extraction of iron ore, thus minimizing the environmental impact associated with resource extraction. Secondly, sustainability is influenced by energy consumption during the production process. Given that steel production is energy-intensive, the type of energy sources utilized greatly impacts sustainability. The adoption of renewable energy, such as solar or wind power, can significantly reduce the carbon footprint of steel billets production. Thirdly, the efficiency of production processes and technologies employed is vital for sustainability. Modern technologies, like electric arc furnaces, offer higher energy efficiency and emit fewer greenhouse gases compared to traditional blast furnaces. Additionally, implementing waste heat recovery systems and optimizing material usage further enhances the sustainability of steel billets production. Proper management of by-products and waste generated during production is another crucial factor. Ensuring appropriate handling, treatment, and disposal of by-products and waste materials, such as slag and dust, is essential to minimize environmental pollution and ensure sustainability. Furthermore, the overall sustainability of steel billets production is influenced by the adoption of responsible and ethical practices throughout the supply chain. This includes upholding labor rights, maintaining health and safety standards, and engaging with the community. Lastly, regulatory frameworks and government policies have a significant impact on sustainability. Stringent environmental regulations, support for clean technologies, and incentives for sustainable practices can encourage the industry to adopt more environmentally friendly production methods. In conclusion, the sustainability of steel billets production is determined by factors such as the raw material source, energy consumption, production processes, waste management, ethical practices, and regulatory frameworks. By addressing these factors, the steel industry can strive towards more sustainable and environmentally friendly production practices.

- Q: What are the common surface defects in steel billets during reheating?

- During the reheating process of steel billets, several common surface defects may occur. These defects can have a negative impact on the quality and integrity of the final product. Some of the most common surface defects in steel billets during reheating include: 1. Scale Formation: When steel billets are exposed to high temperatures, a layer of iron oxide, known as scale, can form on the surface. Scale is brittle and can easily crack or flake off, leading to a rough and uneven surface. 2. Decarburization: Decarburization is the loss of carbon from the surface of the steel billets due to exposure to high temperatures. This can result in a reduced carbon content on the surface, making it prone to cracking, reduced hardness, and poor mechanical properties. 3. Surface Oxidation: Steel billets can undergo oxidation when exposed to oxygen in the air during reheating. This can lead to the formation of a thin layer of oxide on the surface, affecting the surface finish and potentially reducing the corrosion resistance of the steel. 4. Overheating: Overheating during reheating can cause localized melting or partial melting of the steel billets. This can result in surface irregularities, such as pits, cracks, or blisters, which compromise the integrity of the billets. 5. Hot Spots: Uneven heating of the steel billets can lead to the formation of hot spots on the surface. These localized areas of excessive heat can cause surface defects like warping, cracking, or surface defects like scorching or discoloration. 6. Surface Contamination: During reheating, steel billets can come into contact with contaminants, such as dirt, oil, or other foreign materials. These contaminants can adhere to the surface of the billets, leading to surface defects like stains, pitting, or uneven surface finish. 7. Thermal Shock: Rapid changes in temperature during reheating can cause thermal shock, leading to surface defects like cracks or distortions. This can occur when the steel billets are exposed to water or a cooling medium or when there are substantial temperature differences across the surface of the billets. To minimize these surface defects in steel billets during reheating, proper heating techniques, control of heating rates, and the use of protective coatings or atmospheres can be employed. Additionally, regular inspection and quality control measures can help identify and mitigate surface defects before they affect the final product's quality.

- Q: How do steel billets come out?

- I. mining1, iron ore2 limestone mine3, coal mineTwo 、 burden preparation1. Iron ore sintering2 coking coal cokingThree, iron: in the blast furnace, sintering iron ore, limestone, coke, iron ore in the iron elements reduced to metal iron, then the product is pig iron.

- Q: What industries use steel billets?

- Due to their strength, durability, and versatility, steel billets are extensively used in a wide range of industries. The construction industry heavily relies on steel billets for the production of structural components like beams, columns, and girders, which provide vital support and strength in infrastructure projects such as buildings and bridges. In the automotive industry, steel billets are crucial for manufacturing various car parts, including engine components, chassis, and suspension systems. The preference for steel billets in this industry stems from their high strength-to-weight ratio, which enhances fuel efficiency and overall performance. Manufacturing industries like machinery, equipment, and tool production also heavily depend on steel billets. These billets are used to manufacture critical components such as gears, shafts, valves, which require exceptional strength, durability, and precision. Additionally, steel billets play a vital role in the energy sector, particularly in the production of oil and gas pipelines. These pipelines require specific grades of steel billets that can withstand harsh conditions, high pressures, and corrosive environments. Moreover, steel billets have applications in other sectors such as shipbuilding, aerospace, mining, and agriculture. They are widely utilized in any industry where strength, durability, and reliability are paramount. In conclusion, the remarkable mechanical properties of steel billets enable their diverse applications across multiple industries. The demand for steel billets remains strong as they are an indispensable raw material for producing critical components in numerous sectors.

Send your message to us

Prime square alloy steel billet 120mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords