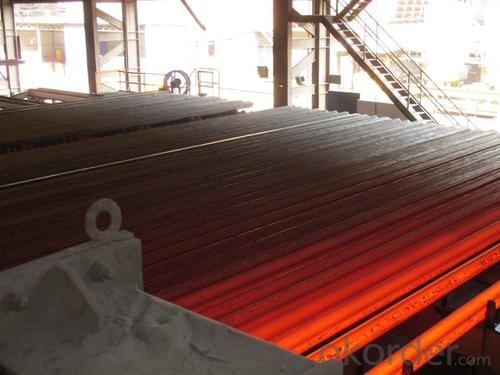

Prime square alloy steel billet 100mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 100mm Q235

Description of Prime square alloy steel billet 100mm Q235

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Main Feature of Prime square alloy steel billet 100mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 100mm Q235

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Specifications of Prime square alloy steel billet 100mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 100mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: What are the main factors affecting the tensile strength of steel billets?

- There are several main factors that affect the tensile strength of steel billets. Firstly, the composition of the steel plays a significant role. The presence of certain elements, such as carbon, manganese, and silicon, can greatly influence the strength of the steel. Carbon, in particular, is a key element in increasing the strength of steel through its ability to form strong interatomic bonds. Secondly, the heat treatment process employed during the production of steel billets is crucial. Heat treatment, such as quenching and tempering, can significantly enhance the tensile strength of the steel by manipulating its microstructure. Quenching involves rapidly cooling the steel, which creates a hardened structure, while tempering involves reheating the steel to a specific temperature to achieve the desired balance of hardness and toughness. Additionally, the grain size of the steel also affects its tensile strength. Fine-grained steel generally exhibits higher strength due to the increased number of grain boundaries, which act as barriers to dislocation movement. On the other hand, coarse-grained steel tends to have lower strength as it allows for easier dislocation movement. Moreover, the presence of impurities or defects in the steel can weaken its tensile strength. Inclusions, such as sulfur, phosphorus, and non-metallic inclusions, can act as stress concentration points and promote crack initiation, leading to reduced strength. Similarly, the presence of voids, porosity, or other structural defects can compromise the overall strength of the steel billets. Lastly, the processing conditions during the manufacturing of steel billets can affect their tensile strength. Parameters such as rolling and forging temperatures, deformation rate, and cooling rate can influence the resulting microstructure and, consequently, the strength of the steel. In conclusion, the main factors affecting the tensile strength of steel billets include the steel composition, heat treatment process, grain size, impurities or defects, and processing conditions. Understanding and optimizing these factors are crucial for producing steel billets with the desired mechanical properties.

- Q: What are the different types of forging processes used for shaping steel billets?

- There are several different types of forging processes that are commonly used for shaping steel billets. These processes include open die forging, closed die forging, and ring rolling. Open die forging is a process in which the steel billet is placed between two flat dies and compressed to shape it. This process is commonly used for larger and simpler shapes, as the steel is not completely enclosed by the dies, allowing for more flexibility in the final shape. Closed die forging, also known as impression die forging, involves the use of specially designed dies that contain cavities in the shape of the desired final product. The steel billet is placed between these dies and compressed, causing the metal to flow and take on the shape of the cavities. This process is commonly used for more complex shapes and allows for greater precision and control over the final product. Ring rolling is a forging process used specifically for shaping steel billets into rings. The billet is placed on a mandrel, and a series of rollers apply pressure to the billet, causing it to deform and take on the shape of a ring. This process is commonly used in the production of seamless rolled rings, which are widely used in industries such as aerospace, oil and gas, and power generation. Overall, these different types of forging processes offer various advantages and are chosen based on the complexity of the desired shape, the required precision, and the specific requirements of the end application.

- Q: How are steel billets used in the manufacturing of automotive engine components?

- Steel billets are used in the manufacturing of automotive engine components as they serve as the raw material from which various engine parts are forged or machined. These billets are heated and shaped into different forms such as crankshafts, connecting rods, camshafts, and valves, which are integral to the functioning of an engine. By using steel billets, manufacturers can ensure the strength, durability, and reliability of these components, resulting in high-performance engines.

- Q: How do steel billets contribute to the food processing industry?

- Steel billets contribute to the food processing industry in several ways. Firstly, steel billets are used to manufacture various machinery and equipment used in the food processing industry. For example, they are used to create conveyor belts, mixers, crushers, and packaging machines, among others. These machines play a crucial role in the processing, handling, and packaging of food products. Steel billets are also used to produce storage tanks and containers, which are essential for the safe and hygienic storage of food ingredients and finished products. These tanks are usually made of stainless steel, which is corrosion-resistant, durable, and easy to clean, ensuring that the food remains uncontaminated and of high quality. Furthermore, steel billets contribute to the construction of infrastructure in the food processing industry. They are used to build food processing plants, warehouses, and cold storage facilities. These structures provide the necessary environment for food processing, such as temperature control and proper ventilation, ensuring food safety and preservation. Additionally, steel billets are crucial for the transportation of food products. They are used to manufacture shipping containers, refrigerated trucks, and railway cars, which enable the efficient and safe transportation of food from one location to another. The strength and durability of steel ensure that the food products are protected during transit, preventing spoilage and contamination. Overall, steel billets are essential in the food processing industry as they contribute to the manufacturing of machinery, storage containers, infrastructure, and transportation systems. Their properties of strength, durability, and corrosion resistance make them ideal for ensuring food safety, quality, and efficiency in all stages of food processing.

- Q: How are steel billets used in the production of oil and gas pipelines?

- Steel billets are essential in the production of oil and gas pipelines as they serve as the initial material for manufacturing these pipelines. Essentially, steel billets are semi-finished steel products that typically have a rectangular or square shape. To manufacture oil and gas pipelines, a series of manufacturing processes are performed on the steel billets. Initially, the billets are heated to high temperatures in a furnace in a process known as billet heating. This heating process increases the malleability of the steel, making it easier to shape. Once the desired temperature is reached, the billets are then passed through a series of rollers to transform their shape into a cylindrical form. This process, called hot rolling, further enhances the mechanical properties of the steel, making it stronger and more durable. Following hot rolling, the steel goes through a process known as quenching and tempering. Quenching involves rapidly cooling the steel to increase its hardness, while tempering is a heat treatment process that reduces the brittleness of the steel, making it less prone to cracking. After these processes, the steel billets are welded together to form the final pipeline. This welding process ensures the integrity and strength of the pipeline, enabling it to withstand the high pressures and harsh environments associated with oil and gas transportation. In conclusion, steel billets play a crucial role in the production of oil and gas pipelines. They serve as the foundational material and undergo various manufacturing processes to transform into durable and high-strength pipes that efficiently transport oil and gas over long distances.

- Q: What are the different methods of steel billet surface grinding?

- There are several methods of steel billet surface grinding, including abrasive grinding, belt grinding, and centerless grinding.

- Q: How do steel billets contribute to the energy industry?

- Steel billets play a crucial role in the energy industry by serving as the primary raw material for the manufacturing of various energy-related equipment and infrastructure. Steel billets, which are semi-finished steel products, are used extensively in the construction of power plants, oil and gas pipelines, wind turbines, and other energy infrastructure projects. One of the key applications of steel billets in the energy industry is in the production of power plant components. Steel billets are used to manufacture various parts of power plants, including boilers, turbines, and generators. These components require a high level of strength, durability, and resistance to high temperatures and pressure, which steel billets can provide. By using steel billets, power plant manufacturers can ensure the reliability and longevity of their equipment, contributing to the overall efficiency and stability of the energy generation process. Steel billets are also essential for the construction of oil and gas pipelines. These pipelines are crucial for the transportation of oil, natural gas, and other energy resources from production sites to refineries and end-users. Steel billets are used to manufacture the large-diameter pipes that form the backbone of these pipelines. The strength, toughness, and corrosion resistance of steel billets ensure the integrity and safety of the pipeline infrastructure, minimizing the risk of leaks or failures that could result in energy supply disruptions or environmental damage. In addition, steel billets are utilized in the production of wind turbines, which are a rapidly growing source of renewable energy. The towers and foundations of wind turbines are typically made of steel, and steel billets are used to manufacture these components due to their exceptional strength and load-bearing capabilities. By utilizing steel billets, wind turbine manufacturers can construct tall and sturdy towers that can support the rotor and ensure the efficient conversion of wind energy into electricity. Overall, steel billets contribute significantly to the energy industry by enabling the construction of robust and reliable infrastructure. The strength, durability, and versatility of steel billets make them an ideal material for energy-related projects, helping to ensure the efficient and sustainable generation, transportation, and utilization of energy resources.

- Q: Can steel billets be used for making decorative items?

- Yes, steel billets can be used for making decorative items. Steel billets can be shaped, molded, and crafted into various designs and forms to create decorative items such as sculptures, furniture, artwork, and architectural features. The strength and durability of steel make it suitable for these purposes while adding a modern and industrial aesthetic to the decorative pieces.

- Q: How are steel billets used in the production of agricultural machinery?

- Steel billets are used in the production of agricultural machinery as a raw material for various components such as gears, shafts, and frames. These billets are melted and molded into the desired shape, providing the necessary strength and durability required for the machinery to effectively perform tasks in the agricultural sector.

- Q: How do steel billets contribute to the infrastructure development sector?

- The infrastructure development sector heavily relies on steel billets for various reasons. Firstly, these billets are crucial in the production of construction materials like rebars, beams, and columns, which are essential for building structures such as buildings, bridges, and roads. By utilizing steel billets, the construction materials gain strength, durability, and stability. Steel possesses exceptional tensile strength, making it capable of withstanding heavy loads and adverse weather conditions. Consequently, this contributes to the safety and longevity of infrastructure projects. Furthermore, steel billets offer versatility and can be easily tailored to specific project requirements. They can be shaped into different forms and sizes, providing engineers and architects with the ability to design structures with precision and efficiency. This flexibility allows for the creation of complex and innovative designs, thus enhancing the overall aesthetic appeal of infrastructure projects. In addition to their structural advantages, steel billets also contribute to the sustainability of the infrastructure development sector. Steel is highly recyclable, and the use of recycled steel reduces the need for newly sourced materials, thereby minimizing environmental impact. Moreover, steel structures can be dismantled and repurposed for other projects, promoting resource efficiency and reducing waste. Moreover, steel billets offer availability and affordability, making them an attractive choice for infrastructure development. Steel production and distribution are widespread, ensuring a steady supply for construction projects. The cost-effectiveness of steel billets enables infrastructure projects to be completed within budget constraints, ensuring cost efficiency for both private and public investments. In conclusion, steel billets play a vital role in the infrastructure development sector. They provide the necessary raw material for construction materials, ensure strength and durability, allow for customization and innovation, promote sustainability, and offer cost-effectiveness. The utilization of steel billets significantly contributes to the growth and advancement of the infrastructure sector, enabling the construction of safe, resilient, and visually appealing structures that support economic development and improve the quality of life for communities.

Send your message to us

Prime square alloy steel billet 100mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords