Prime Steel Billet Q275, 20MnSi, 5SP,Q235 for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STEEL BILLET

1.Brief description

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

2.Features

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

3.Processing

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

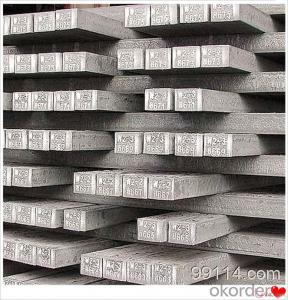

4.Pictures

5.Usage

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

6.Detailed specification

Hot rolled billet steel

Size: 50x50mm-180x180mm

Steel Grade: 3SP, 5SP,Q195,Q235,Q255,Q275 Length:3m-12m

MOQ: 1000MT/size

Payment term: TT or LC

Packing: in bulk , bundle

Shipment: by container , bulk vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: 15-30 days after the deposit

Loading port:Tianjin, or other port China

Origin : China

Inspection:Third party inspection before loading.

- Q: How long do steel billets last?

- The longevity of steel billets varies depending on multiple factors, including their storage conditions and utilization. Provided that they are stored appropriately in a controlled environment with low humidity and shielded from corrosion, steel billets can endure indefinitely. Conversely, if they are exposed to harsh weather, excessive moisture, or corrosive substances, their lifespan can be significantly diminished. As for their usage, steel billets are typically melted and transformed into other steel products, such as bars, rods, and beams. The lifespan of the final product hinges on its specific application and the maintenance practices implemented. Generally, steel products are renowned for their durability and longevity, rendering them a dependable option in numerous industries.

- Q: Can steel billets be used in the manufacturing of machinery?

- Steel billets have the capability to be utilized in the production of machinery. These semi-finished metal products are typically either hot rolled or forged into various shapes, such as bars, rods, or sheets. Machinery components like gears, shafts, bearings, and structural frames are manufactured using these billets as the raw material. The utilization of steel billets in machinery manufacturing offers numerous benefits. Steel is renowned for its exceptional strength, durability, and resistance to wear, making it a suitable choice for heavy-duty applications. Furthermore, steel can be easily machined, welded, and molded into intricate shapes, facilitating the production of complex machinery parts. Moreover, due to its high melting point and thermal conductivity, steel is an ideal material for applications involving high temperatures or requiring heat transfer. Overall, steel billets are extensively employed in machinery manufacturing due to their outstanding mechanical properties, versatility, and dependability.

- Q: What are the different surface treatments for improved wear resistance in steel billets?

- Steel billets can be subjected to various surface treatments to enhance their wear resistance. These treatments aim to increase the durability and longevity of the steel, making it more resilient against wear and tear. One widely utilized surface treatment method is case hardening. This technique involves heating the steel billets to high temperatures and then rapidly cooling them in a quenching medium, like oil or water. This process results in the formation of a tough outer layer, known as a case, while maintaining a comparatively softer core. The hardened case provides exceptional wear resistance, while the softer core retains toughness and ductility. Nitriding is another surface treatment option for improved wear resistance. This process entails introducing nitrogen into the surface of the steel billets, typically through a gas or plasma-based approach. The nitrogen permeates the steel and forms a hard layer of nitride on the surface. This nitride layer significantly enhances the hardness and wear resistance of the steel, making it suitable for applications requiring high wear resistance. Hard chrome plating is a third surface treatment technique. It involves electroplating a layer of chromium onto the surface of the steel billets. The chromium layer offers excellent wear and corrosion resistance, making it ideal for applications where the steel will be exposed to harsh environments or abrasive substances. Furthermore, advanced surface treatment methods such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) can be employed to enhance the wear resistance of steel billets. These processes involve depositing a thin film of a wear-resistant material, like titanium nitride or diamond-like carbon, onto the steel's surface. These thin films create a hard and low-friction surface, improving wear resistance and reducing frictional losses. In summary, these surface treatments present a diverse range of options to improve the wear resistance of steel billets. The choice of treatment depends on factors such as the specific application requirements, desired level of wear resistance, and budget constraints. Seeking guidance from materials experts or surface treatment specialists can aid in determining the most suitable treatment for a particular steel billet application.

- Q: Is there an export duty? Or is there a tax refund?

- Your specification 13*13*6 or 12 meters, this is a square cross section, so 7207120000 this can not be used, your billet carbon content is 0.17 to 0.23% less than 0.25%, so we must use the following7207190000 Other Billets with carbon content less than 0.25%Export tax refund: 0%MFN country of import tariff: 2%General customs duties: 11%Export tariff rate: 0%VAT: 17%

- Q: What is the role of steel billets in the construction of bridges and tunnels?

- The construction of bridges and tunnels heavily relies on steel billets, which are semi-finished steel products that undergo further processing to create various structural components for the construction industry. For bridges, steel billets are utilized to manufacture steel beams, girders, and columns, forming the core structure of the bridge. These components are essential for providing the required strength and stability to support the bridge's weight and the traffic it carries. Steel billets are chosen due to their high strength-to-weight ratio, making them ideal for constructing long-span and heavy-load bridges. Similarly, in tunnel construction, steel billets are used to create reinforcement bars or rebars. These rebars are embedded within the concrete walls and floors of tunnels, offering additional strength and support to withstand the immense pressure and weight of the surrounding soil or rock. Additionally, steel billets are also employed in fabricating tunnel linings, which protect the tunnel walls from erosion, corrosion, and other forms of deterioration. The utilization of steel billets in bridge and tunnel construction provides several advantages. Firstly, steel is a highly durable and resilient material, capable of withstanding extreme forces, temperature variations, and environmental conditions. This durability ensures the long-lasting nature and structural integrity of bridges and tunnels, reducing maintenance and repair costs over time. Secondly, steel billets can be easily shaped, molded, and welded into various intricate shapes and sizes, allowing for flexibility in design and construction. This versatility enables engineers to create innovative and efficient bridge and tunnel structures, accommodating different architectural and engineering requirements. Lastly, steel billets are renowned for their excellent load-bearing capacity, making them suitable for high-traffic areas such as bridges and tunnels. They can withstand heavy loads and distribute the weight evenly, minimizing the risk of structural failure or collapse. In conclusion, steel billets play a crucial role in the construction of bridges and tunnels by providing the necessary strength, durability, and flexibility. They form the core structure of these constructions, ensuring their stability, longevity, and ability to withstand various environmental and operational challenges.

- Q: How do steel billets contribute to the energy efficiency of a structure?

- Steel billets contribute to the energy efficiency of a structure in several ways. Firstly, steel billets are a primary raw material used in the production of structural steel, which is known for its high strength-to-weight ratio. This means that steel structures can bear heavy loads without requiring excessive amounts of material, resulting in lighter and more energy-efficient structures. The reduced weight of the structure translates to lower transportation costs and less energy consumption during construction. Furthermore, steel billets can be easily molded and shaped into various forms, allowing for the design and construction of more efficient and streamlined structures. The flexibility of steel as a construction material enables engineers and architects to create innovative designs that maximize energy efficiency. For example, steel can be used to create long-span structures, reducing the need for additional support columns and optimizing natural lighting and ventilation, which in turn reduces the need for artificial lighting and HVAC systems. In addition, steel is highly durable and requires minimal maintenance over its lifespan. This durability not only extends the life of the structure but also reduces the amount of energy and resources required for repairs and replacements. Steel structures also have excellent fire resistance properties, which can contribute to energy efficiency by minimizing fire-related damages and the subsequent energy consumption associated with rebuilding or repairing. Lastly, steel is a highly recyclable material. At the end of a structure's life, steel components can be easily salvaged and recycled, reducing the demand for new steel production and conserving natural resources. The recycling process for steel is energy-efficient compared to the production of virgin steel, further reducing the carbon footprint of the structure. Overall, steel billets contribute to the energy efficiency of a structure through their high strength-to-weight ratio, flexibility in design, durability, fire resistance, and recyclability. These properties allow for the construction of lighter, more efficient structures that require less energy during construction, operation, and maintenance while minimizing environmental impact.

- Q: What are the main factors affecting the dimensional stability of steel billets?

- There are several main factors that can affect the dimensional stability of steel billets. 1. Temperature: One of the most significant factors is temperature. Steel billets can undergo thermal expansion or contraction depending on the temperature they are exposed to. Changes in temperature can cause the billets to expand or contract, leading to dimensional changes. It is crucial to control the temperature during the manufacturing process and subsequent cooling stages to minimize these effects. 2. Cooling rate: The rate at which the steel billets cool down after being heated also affects their dimensional stability. Rapid cooling can result in internal stresses within the billet, causing it to warp or distort. On the other hand, slow cooling can lead to uneven cooling and uneven dimensional changes. 3. Composition: The chemical composition of the steel billets plays a significant role in their dimensional stability. Different alloying elements, impurities, and carbon content can influence the material's behavior during heating and cooling. For instance, higher carbon content can increase the likelihood of warping or distortion. 4. Mechanical stresses: Mechanical stresses from handling, transportation, or machining processes can impact the dimensional stability of steel billets. Excessive bending, twisting, or pressure can cause permanent deformation or residual stresses within the billet, affecting its overall dimensional stability. 5. Heat treatment: The heat treatment process can also influence the dimensional stability of steel billets. Different heat treatment methods, such as annealing, quenching, or tempering, can introduce internal stresses or phase transformations that may alter the billet's dimensions. 6. Manufacturing techniques: The processes used during the production of steel billets, such as casting, rolling, or forging, can have an impact on their dimensional stability. Inadequate control or inconsistencies in these manufacturing techniques can lead to variations in the billet's dimensions. It is crucial to consider and control these factors to ensure the dimensional stability of steel billets, as any dimensional changes can affect the subsequent processing steps and the final product's quality.

- Q: What are the main disadvantages of using steel billets?

- Using steel billets in various industries comes with several disadvantages. To begin with, one major drawback of steel billets is their high cost. The manufacturing process of steel billets is complex, involving the melting and casting of steel, which can be quite expensive. Consequently, this cost is then passed on to the end product, making it less affordable for consumers. Moreover, steel billets tend to be heavy and bulky, making transportation and handling challenging. The weight and size of steel billets contribute to logistical difficulties in the supply chain, leading to increased costs and potential delays. Another disadvantage is the limited availability of steel billets. Steel production requires a substantial amount of resources and energy, and the availability of raw materials can be restricted, resulting in potential disruptions in the supply chain. This scarcity can have a negative impact on industries heavily reliant on steel billets for their operations. Furthermore, steel billets have limited shape flexibility. They are typically produced in standardized sizes and shapes, making customization for specific design requirements difficult. This lack of flexibility can be a significant drawback for industries that necessitate intricate and unique shapes for their products. Moreover, steel billets are susceptible to corrosion if not properly treated. Exposure to moisture and certain environments can lead to rust and degradation, reducing the lifespan and durability of products made from steel billets. Regular maintenance and anti-corrosion treatments are essential to mitigate this disadvantage. Lastly, the production of steel billets has a significant environmental impact. The manufacturing process emits greenhouse gases and consumes substantial amounts of energy and water. These environmental concerns have resulted in increased scrutiny and regulations on steel production, thereby adding extra costs and complexities to the use of steel billets. In conclusion, while steel billets offer advantages in terms of strength and durability, they also come with several drawbacks. These include high costs, transportation challenges, limited availability, lack of shape flexibility, susceptibility to corrosion, and environmental impact. Industries must carefully consider these disadvantages when evaluating the use of steel billets in their operations.

- Q: What are the different types of steel billet defect detection methods?

- There are several different types of steel billet defect detection methods, including visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. Each method has its own advantages and limitations, and they are often used in combination to ensure comprehensive defect detection in steel billets.

- Q: How are steel billets inspected for quality?

- Steel billets are typically inspected for quality using various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and dye penetrant testing. These tests help identify any surface defects, cracks, or internal flaws in the billets, ensuring that they meet the required quality standards before further processing.

Send your message to us

Prime Steel Billet Q275, 20MnSi, 5SP,Q235 for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords