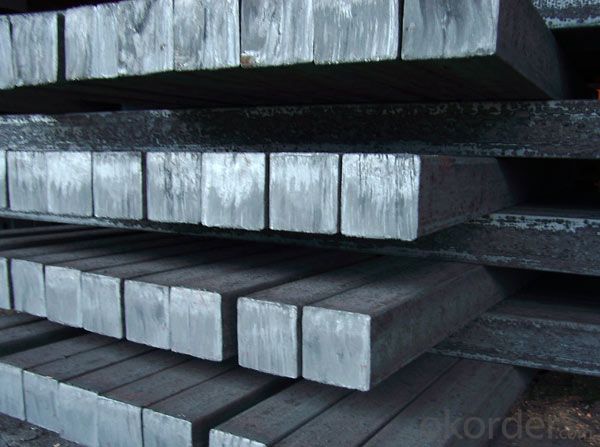

Steel Rectangle Billet Bars Raw Material for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Rectangle Billet Bars Raw Material for Sale with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Rectangle Billet Bars Raw Material for Sale are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Rectangle Billet Bars Raw Material for Sale are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Packaging & Delivery:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the major steel billet producing countries?

- The major steel billet producing countries are China, India, Russia, Japan, and the United States. China is by far the largest producer of steel billets, accounting for over half of the global production. This is due to the country's massive steel industry, which has experienced significant growth in recent decades. India is the second-largest producer, with a rapidly expanding steel sector as well. Russia is known for its strong steel industry and is the third-largest producer. Japan, although its steel production has declined in recent years, still remains a significant player in the steel billet market. Lastly, the United States is a major producer of steel billets, with a focus on high-quality specialty steel products. These countries play a crucial role in meeting the global demand for steel billets, which are essential raw materials for various industries, including construction, automotive, and infrastructure.

- Q: What are the different methods of steel billet inspection?

- There are several different methods of steel billet inspection that are commonly used in the manufacturing industry. These methods are employed to ensure the quality and integrity of the steel billets before they are further processed into various end products. Some of the most common methods of steel billet inspection include: 1. Visual Inspection: This is the simplest and most basic method of inspection, where trained inspectors visually examine the billets for any surface defects, such as cracks, pits, or any other irregularities. This method is typically used as an initial screening process before more advanced inspection techniques are employed. 2. Ultrasonic Testing: Ultrasonic testing utilizes high-frequency sound waves to detect any internal defects or inconsistencies within the steel billets. This method involves the use of a transducer that emits sound waves into the billet, and the reflected waves are analyzed to identify any flaws or abnormalities. Ultrasonic testing is effective in detecting internal defects like voids, inclusions, or cracks. 3. Magnetic Particle Inspection: This method is particularly useful for detecting surface and near-surface defects in steel billets. It involves applying a magnetic field to the billet and then applying iron particles to the surface. The particles will cluster around any magnetic leakage caused by surface cracks or defects, making them easily visible to the inspector. 4. Eddy Current Testing: Eddy current testing is a non-destructive method used to detect surface and near-surface defects in conductive materials, including steel billets. It involves passing an alternating current through a coil, creating an electromagnetic field. Any changes in the electromagnetic field caused by defects in the billet's surface are detected and analyzed, allowing for the identification of flaws. 5. X-ray Inspection: X-ray inspection is a widely used method for inspecting steel billets. It involves passing X-rays through the billet and capturing the resulting image on a film or digital detector. This method is highly effective in detecting both internal and external defects, such as cracks, voids, inclusions, or segregation. These are just a few of the commonly employed methods of steel billet inspection. Each method has its advantages and limitations, and the choice of inspection technique depends on factors such as the type of defect being targeted, the size and shape of the billets, and the specific requirements of the end product. By utilizing a combination of these inspection methods, manufacturers can ensure the quality and reliability of the steel billets they produce.

- Q: What are the different types of shearing machines used for steel billets?

- There are several types of shearing machines used for steel billets, including hydraulic shears, mechanical shears, and rotary shears. Hydraulic shears use hydraulic power to provide a smooth and powerful cutting action, while mechanical shears rely on a mechanical lever system for cutting. Rotary shears, on the other hand, operate by rotating the cutting blades to shear the steel billets. These different types of shearing machines offer various advantages and are used depending on the specific requirements of the steel billet cutting process.

- Q: How do steel billets contribute to the fire resistance of a structure?

- The fire resistance of a structure is primarily enhanced by the presence of steel billets, which possess a high melting point and the ability to conduct heat effectively. Unlike wood or concrete, steel has a considerably higher melting point, ranging from 1370 to 1538 degrees Celsius (2500 to 2800 degrees Fahrenheit). The high melting point of steel billets allows them to withstand intense heat without compromising their structural integrity during a fire. Consequently, the steel framework of a building remains intact even when exposed to elevated temperatures, reducing the likelihood of warping, softening, or collapse. Moreover, steel's excellent heat conductivity enables it to rapidly absorb heat and transfer it away from the affected area when exposed to fire. This characteristic prevents the fire from spreading and limits the damage inflicted upon the structure. Additionally, the heat dissipation property of steel helps prevent the transmission of heat to non-steel components like walls or floors, thereby impeding the fire's rapid propagation. Furthermore, steel billets possess a low thermal expansion coefficient, meaning that their expansion rate is comparatively slow when subjected to extreme heat. This attribute prevents excessive movement or deformation of the steel structure during a fire, ensuring the maintenance of stability and structural integrity. In conclusion, steel billets play a vital role in enhancing the fire resistance of a structure by offering high heat resistance, efficient heat conduction, and minimal thermal expansion. These properties render steel an ideal choice for constructing fire-resistant buildings, ensuring increased safety for occupants and reducing the risk of total or partial collapse in the event of a fire.

- Q: What is the role of steel billets in the construction of dams and reservoirs?

- Steel billets play a crucial role in the construction of dams and reservoirs. These billets, which are semi-finished steel products, serve as the primary raw material for manufacturing various components and structures needed in the construction process. One of the main applications of steel billets in dam and reservoir construction is for the production of reinforced concrete. Reinforced concrete is a composite material that combines the strength and durability of steel with the moldability and versatility of concrete. Steel billets are used to produce steel reinforcement bars, commonly known as rebars, which are embedded within the concrete to enhance its tensile strength and prevent cracking under heavy loads. These rebars provide structural support to the dam or reservoir, ensuring its stability and longevity. Additionally, steel billets are utilized in the fabrication of gates, penstocks, and other mechanical components required in dams and reservoirs. These components are crucial for regulating the flow of water, controlling the water level, and managing the release of water from the reservoir. Steel billets are forged, rolled, or machined to create these specialized components, ensuring their strength, reliability, and resistance to corrosion. Furthermore, steel billets are used in the construction of spillways, which are designed to safely discharge excess water from reservoirs during periods of heavy rainfall or flood. The spillway gates, channels, and other structures are often made from steel billets, as they need to withstand high water pressure and turbulent flow conditions. In summary, steel billets are indispensable in the construction of dams and reservoirs. They are used to produce reinforced concrete, providing structural support and increasing the overall strength of the structure. Steel billets are also employed in the manufacturing of gates, penstocks, spillways, and other mechanical components, guaranteeing the efficient operation and long-term durability of these essential water management infrastructure.

- Q: How can steel billets be customized for specific applications?

- Steel billets can be customized for specific applications through various processes such as heat treatment, alloying, and shaping. Heat treatment techniques like quenching and tempering can enhance the billet's strength, hardness, and toughness. Alloying elements can be added to improve specific properties like corrosion resistance or high-temperature performance. Additionally, the billets can be shaped through processes like rolling, forging, or extrusion to achieve the desired dimensions and form required for specific applications.

- Q: What are the main factors that determine the sustainability of steel billets production?

- The main factors that determine the sustainability of steel billets production include the source of raw materials, energy efficiency in the production process, waste management, carbon emissions, water usage, and adherence to environmental regulations. Additionally, the implementation of sustainable practices such as recycling, reducing greenhouse gas emissions, and promoting responsible sourcing contribute to the overall sustainability of steel billets production.

- Q: What are the main factors affecting the hardenability of steel billets?

- The main factors affecting the hardenability of steel billets are the carbon content, alloying elements, cooling rate, and the size and shape of the billet.

- Q: What are the different types of casting processes used for shaping steel billets?

- There are several different types of casting processes used for shaping steel billets. These processes include: 1. Continuous Casting: This is the most commonly used method for casting steel billets. In this process, molten steel is poured into a water-cooled mold that is continuously moving. As the steel solidifies, it is continuously pulled out of the mold, resulting in a continuous billet. This process is efficient and allows for high production rates. 2. Centrifugal Casting: In this process, molten steel is poured into a rotating mold. The centrifugal force generated by the rotation distributes the molten metal evenly along the mold walls, resulting in a cylindrical billet. This method is used to produce high-quality and defect-free billets. 3. Ingot Casting: This is a traditional method of casting steel billets. In this process, molten steel is poured into a mold and allowed to solidify. The solidified steel, known as an ingot, is then removed from the mold and further processed to obtain the desired shape of the billet. Ingot casting allows for flexibility in terms of billet shape and size. 4. Sand Casting: This process is used for producing large and complex steel billets. It involves creating a mold using a mixture of sand and a binder material. Molten steel is then poured into the mold, and once it solidifies, the mold is removed to reveal the billet. Sand casting allows for the production of custom-shaped billets but is a slower and less precise process compared to others. 5. Investment Casting: Also known as lost-wax casting, this process is suitable for complex and intricate shapes. In investment casting, a wax pattern of the desired billet shape is created. The wax pattern is then coated with a ceramic shell, and the wax is melted out, leaving behind a hollow mold. Molten steel is poured into the mold, and once it solidifies, the ceramic shell is broken to retrieve the billet. Each of these casting processes has its advantages and disadvantages, and the choice of process depends on factors such as the desired billet shape, size, production volume, and quality requirements.

- Q: How do steel billets contribute to the renewable energy sector?

- Steel billets are essential in the renewable energy sector as they are used to manufacture a wide range of components and infrastructure required for renewable energy technologies. These billets serve as the raw material for the production of wind turbine towers, solar panel frames, and hydroelectric infrastructure, among others. By providing the necessary strength and durability, steel billets enable the construction and maintenance of renewable energy systems, thereby contributing to the growth and sustainability of the sector.

Send your message to us

Steel Rectangle Billet Bars Raw Material for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords