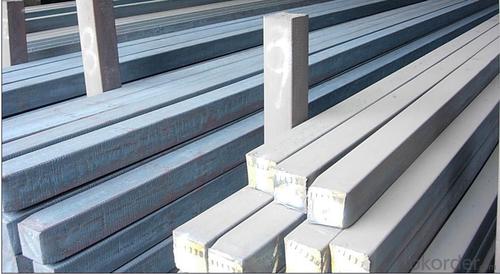

Prime quality square alloy steel billet 120mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime quality square alloy steel billet 120mm Q235

Description of Prime quality square alloy steel billet 120mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime quality square alloy steel billet 120mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime quality square alloy steel billet 120mm Q235

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Prime quality square alloy steel billet 120mm Q235

Product | Prime quality square alloy steel billet 120mm Q235 |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime quality square alloy steel billet 120mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Can steel billets be customized in terms of shape and size?

- Yes, steel billets can be customized in terms of shape and size. They can be fabricated into various shapes and sizes to meet specific requirements and applications.

- Q: How are steel billets used in the manufacturing of defense equipment?

- Steel billets are used in the manufacturing of defense equipment as they serve as the raw material for forging various components and parts. These billets are heated, shaped, and machined to create the necessary structures, such as gun barrels, armor plates, and gears, which are crucial for the production of durable and reliable defense equipment.

- Q: How are steel billets used in the production of construction parts?

- Steel billets are an important raw material in the production of construction parts. They are essentially semi-finished steel products that are cast into square or rectangular shapes. These billets are then further processed and transformed into various construction components like beams, columns, rods, and bars. The first step in utilizing steel billets is heating them in a furnace to a temperature that allows for easy deformation and shaping. Once the billets reach the desired temperature, they are passed through a series of rolling mills, where they undergo hot rolling. This process involves repeatedly passing the billets through multiple pairs of rollers to gradually reduce their size and shape them into the required form, such as beams or rods. Hot rolling not only helps to shape the billets but also improves their mechanical properties, such as strength, toughness, and ductility. The resulting steel products are then cut to the desired lengths and further processed, if necessary, to meet specific construction requirements. These steel components made from billets are widely used in construction projects. For instance, beams made from steel billets are commonly used to provide structural support in buildings and bridges. They offer superior strength and load-bearing capacity, making them ideal for withstanding heavy loads and ensuring the overall stability of the structure. Steel rods and bars, on the other hand, are widely used in reinforced concrete construction. These components are embedded within the concrete to increase its tensile strength and prevent cracks from forming. They are essential in the construction of foundations, slabs, walls, and other structural elements that require added reinforcement. In summary, steel billets play a crucial role in the production of construction parts by serving as the starting point for the manufacturing process. Through hot rolling and subsequent processing, these billets are transformed into various steel components that are used to provide structural support, reinforcement, and durability in construction projects.

- Q: Are steel billets used in the production of automotive parts?

- Indeed, the utilization of steel billets in the fabrication of automotive parts is widespread. These semi-finished goods, known as steel billets, are typically employed as primary materials in diverse manufacturing procedures. Often, they undergo forging or rolling procedures to attain the desired dimensions and structure, thus enabling the production of engine parts, axles, gears, springs, and chassis for automobiles. Due to their outstanding strength, endurance, and malleability, steel billets prove to be an optimal selection when manufacturing automotive components demanding exceptional performance and dependability.

- Q: What are the main challenges in the distribution of steel billets?

- The main challenges in the distribution of steel billets include ensuring efficient transportation and logistics, managing inventory levels effectively, minimizing damage during handling and storage, meeting varying customer demands and specifications, and navigating international trade and customs regulations. Additionally, optimizing the supply chain, maintaining consistent quality control, and addressing price fluctuations and market volatility pose further challenges in the distribution of steel billets.

- Q: What are the different surface treatments applied to alloy steel billets?

- There are several different surface treatments that can be applied to alloy steel billets to enhance their properties and improve their performance. One common surface treatment is shot blasting, which involves bombarding the surface of the billets with small metal or ceramic particles at high velocity. This process helps to remove any impurities or contaminants on the surface, creating a clean and uniform surface finish. Shot blasting also promotes adhesion of subsequent coatings or treatments that may be applied to the billets. Another surface treatment is pickling, which involves immersing the billets in an acid solution to remove oxides and scale from the surface. This process helps to improve the surface quality and removes any surface defects, preparing the billets for further processing or treatments. A popular surface treatment for alloy steel billets is heat treatment, which involves subjecting the billets to controlled heating and cooling processes to alter their microstructure and improve their mechanical properties. Heat treatment can be used to increase the hardness, strength, and toughness of the billets, making them more suitable for specific applications. Additionally, alloy steel billets can be coated with various protective coatings to enhance their corrosion resistance and improve their durability. Common coating techniques include hot-dip galvanizing, electroplating, and painting. These coatings provide a barrier between the alloy steel surface and the environment, preventing corrosion and extending the lifespan of the billets. In summary, the different surface treatments applied to alloy steel billets include shot blasting, pickling, heat treatment, and protective coatings. These treatments help to improve the surface quality, enhance mechanical properties, and protect the billets from corrosion, ultimately ensuring optimal performance in various applications.

- Q: What is the average weight of a steel billet?

- The average weight of a steel billet can vary depending on its size and dimensions. However, a typical steel billet can weigh anywhere between 1,000 kilograms (2,204 pounds) to 5,000 kilograms (11,023 pounds). These weights are typical for industrial-grade steel billets used in various manufacturing processes such as forging, rolling, and extrusion. It's important to note that the weight of a steel billet can also be customized based on specific requirements and industry standards.

- Q: How are steel billets used in the production of forged parts?

- Steel billets are an essential component in the production of forged parts. They serve as the starting material from which the desired shape and size of the forged part is created. To begin the process, steel billets are heated to a specific temperature to make them more malleable. This temperature, known as forging temperature, allows the steel to be easily deformed without cracking or breaking. Heating the billets also improves their structural integrity and makes them more resistant to deformation during the forging process. Once the steel billets reach the desired temperature, they are placed onto a forging press or hammer. The press applies immense pressure to the billets, forcing them to take the shape of the die or mold in which they are placed. This process is known as forging and it allows for the creation of complex shapes and intricate details that cannot be achieved through other manufacturing methods. The forged parts produced from steel billets are known for their exceptional strength, durability, and resistance to wear and tear. They are widely used in various industries, including automotive, aerospace, oil and gas, and construction. Forged parts can range from small components like gears and bolts to larger items such as crankshafts, connecting rods, and turbine blades. In summary, steel billets are used in the production of forged parts by providing the raw material that is shaped and formed through the forging process. The resulting forged parts possess superior mechanical properties and are vital components in many industrial applications.

- Q: What are the different sizes and shapes of steel billets?

- Steel billets come in a variety of sizes and shapes depending on the intended use and production method. Generally, steel billets are rectangular in shape with varying dimensions. Commonly used sizes range from 100mm x 100mm to 300mm x 300mm, with lengths typically falling between 3 and 12 meters. In addition to the standard rectangular shape, steel billets can also be produced in other shapes to cater to specific requirements. Some examples include round billets, square billets, and octagonal billets. Round billets, as the name suggests, have a circular cross-section, while square billets have four equal sides. Octagonal billets have eight sides, providing increased surface area and improved thermal conductivity. The choice of size and shape of steel billets depends on various factors such as the type of steel being produced, the desired strength and durability, and the manufacturing process. These factors influence the final product's properties and its ability to withstand specific applications, such as construction, automotive manufacturing, or machinery production.

- Q: How are steel billets used in the production of molds?

- Steel billets are an important component in the production of molds as they serve as the raw material for creating the mold itself. The process begins by selecting a suitable steel billet, which is typically a solid rectangular or square piece of steel. Once the steel billet is chosen, it undergoes a series of manufacturing processes to transform it into a mold. Firstly, the billet is heated to a high temperature, known as the forging temperature, which makes it malleable and easier to work with. This heating process is crucial as it allows the steel to be shaped and molded into the desired form. After heating, the steel billet is subjected to a variety of shaping techniques such as rolling, pressing, or hammering. These methods help to shape the steel into the desired mold design, which could be a simple or complex shape depending on the application. Once the desired shape is achieved, the steel billet is cooled down and undergoes further processes such as machining, grinding, and polishing to refine the mold's surface finish and dimensional accuracy. This ensures that the mold is precise and capable of producing high-quality products. Overall, steel billets are used in the production of molds as the base material that is shaped and refined to create a customized mold design. These molds are then used in various industries such as automotive, aerospace, and manufacturing to produce a wide range of products.

Send your message to us

Prime quality square alloy steel billet 120mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords