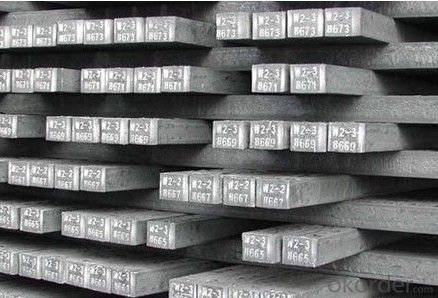

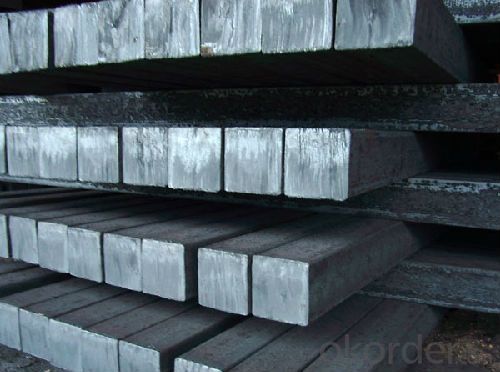

Square Steel Billet, Square Bar, Prime Steel Billet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Square Steel Billet, Square Bar, Prime Steel Billet at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Square Steel Billet, Square Bar, Prime Steel Billet are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Square Steel Billet, Square Bar, Prime Steel Billet are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195/Q235/Q275/20MnSi/3SP/5SP

Certificates: ISO, SGS, BV

size:60*60/90*90/100*100/120*120/150*150

Length: 6m/12m,

Packaging: Export packing, nude packing, bundled

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: What are the main challenges in the transportation of steel billets?

- The main challenges in the transportation of steel billets include ensuring proper handling and securing of the heavy and bulky loads, preventing damage or deformation during loading and unloading processes, and complying with safety regulations for transporting hazardous materials. Additionally, factors such as limited availability of specialized equipment, fluctuations in fuel prices, and coordinating logistics for long-distance shipments can pose challenges for efficient and cost-effective transportation of steel billets.

- Q: How are steel billets used in the production of marine components?

- Steel billets are an essential component in the manufacturing process of marine parts, including ship propellers, hulls, and offshore structures. These components must possess high levels of strength, durability, and resistance to corrosion in order to endure the harsh conditions of the marine environment. Steel billets are essentially semi-finished products that take the form of solid rectangles. They are typically created by pouring liquid steel into molds and allowing it to cool and solidify. These billets are then utilized as raw materials in the production of various marine components. To begin the production of marine components, steel billets are first heated to a specific temperature in order to soften the material. This process, known as hot rolling, enables the billets to be shaped into different forms such as bars, rods, or sheets, depending on the specific requirements of the component being manufactured. Once the desired shape is achieved, the steel billets undergo additional processes such as forging, machining, and welding. Forging involves applying pressure to the heated billets to mold them into the desired marine component. Machining is then performed to refine the shape, size, and surface finish of the component, ensuring it meets the required specifications. Welding is used to join different steel billets or sections together to create larger marine components, such as ship hulls. The utilization of steel billets in the production of marine components offers numerous advantages. Steel is a robust and durable material that can withstand the extreme forces and conditions encountered in the marine environment. Furthermore, steel possesses excellent corrosion resistance properties, which are vital for marine components exposed to saltwater and other corrosive agents. In conclusion, steel billets play a critical role in the manufacturing of marine components. They serve as the raw materials that are shaped, refined, and joined together to create strong, durable, and corrosion-resistant components for ships, offshore structures, and other marine applications.

- Q: What is the role of steel billets in the construction of offshore platforms?

- Steel billets play a crucial role in the construction of offshore platforms. These platforms are massive structures that are installed in the open sea to extract oil or gas from beneath the ocean floor. Due to the harsh environmental conditions and the need for utmost safety and durability, steel billets are widely used in their construction. One of the primary functions of steel billets is to provide the raw material for the fabrication of various components of offshore platforms. Billets are large, semi-finished steel products that are typically used as starting material for the production of other steel products. They are cast into a specific shape, usually a square or a rectangle, and have a solid cross-section. Offshore platforms require steel with exceptional strength, corrosion resistance, and impact toughness to withstand the challenging conditions they face, such as strong waves, harsh weather, and extreme temperatures. Steel billets are often made from high-strength alloyed steels, which offer superior mechanical properties and resistance to corrosion. These billets are then further processed to manufacture different structural elements of offshore platforms, including beams, columns, braces, and other support structures. These components must be able to support the weight of the platform itself, as well as withstand the forces generated by ocean waves, wind, and the extraction process. Moreover, steel billets are also used in the production of pipes and tubes, which are vital for transporting oil and gas from beneath the seabed to the platform or to the shore. These pipes need to be strong, durable, and resistant to corrosion to ensure the safe and efficient flow of hydrocarbons. In summary, steel billets serve as the building blocks for the construction of offshore platforms. They provide the raw material for fabricating various structural components, ensuring the strength, durability, and safety of these massive structures in the challenging offshore environment.

- Q: the ear has burrs, is it the billet problem or the rolling mill problem, will it be caused by the blowhole of the billet?

- Do not worry, you can go to the hospital to check

- Q: Can steel billets be used in the production of appliances?

- Yes, steel billets can be used in the production of appliances. Steel billets, which are semi-finished products of steel, can be further processed and shaped into various components and parts that are used in appliances manufacturing. The high strength and durability of steel make it a suitable material for appliances, providing stability and reliability to the finished products.

- Q: What are the different types of steel billet machining processes?

- There are several types of steel billet machining processes, including turning, milling, drilling, and grinding. Each of these processes involves different techniques and tools to shape and refine the steel billet into the desired form or component.

- Q: How are steel billets used in the manufacturing of automotive parts?

- Steel billets are an essential raw material used in the manufacturing of automotive parts. These billets, which are typically short, solid pieces of steel, serve as the starting point for various automotive components. Firstly, steel billets are heated and then passed through a series of rolling mills to convert them into different shapes and sizes. This process, known as hot rolling, allows the steel billets to be transformed into bars, rods, or sheets that can be further machined or formed into automotive parts. The automotive industry relies heavily on steel billets to produce a wide range of components, such as engine blocks, crankshafts, suspension parts, and chassis frames. These parts require high strength and durability to withstand the demanding conditions of vehicles. Engine blocks, for example, are typically made from cast iron or aluminum alloys produced from steel billets. The billets are melted and poured into molds to create the desired shape, which forms the foundation of the engine. Similarly, crankshafts, which transfer power from the engine to the wheels, are often forged from steel billets to ensure strength and precision. Suspension parts, such as control arms and torsion bars, also rely on steel billets for their manufacturing. These parts need to withstand the forces and impact of the road, and steel provides the necessary strength and resilience. Billets are machined and shaped to create the required geometry and then assembled with other components to form the suspension system. Additionally, steel billets are used in the production of chassis frames, which provide the structural integrity and support for the entire vehicle. These frames are typically made from steel tubes or sections formed from billets. The billets are shaped, welded, and joined together to create a strong and rigid framework that gives stability and ensures safety. In conclusion, steel billets play a crucial role in the manufacturing of automotive parts. With their versatility and strength, they are transformed into various components that form the backbone of vehicles, ensuring durability, performance, and safety on the road.

- Q: How are steel billets used in the manufacturing of bearings?

- Steel billets are an essential raw material used in the manufacturing of bearings. Bearings are mechanical components that facilitate smooth rotational or linear movement between two parts. Steel billets, which are solid blocks of steel, are first heated and then subjected to a forging process to shape them into the desired dimensions and form. This process involves applying high pressure to the heated billets, which results in plastic deformation and the creation of a rough bearing shape. After the initial forging, the rough-shaped billets undergo further precision machining processes to refine their dimensions and improve their surface finish. These processes include turning, grinding, and polishing, which ensure the final product meets the required specifications for bearing performance. Once the billets are machined to the appropriate size and shape, they are heat-treated to enhance their mechanical properties. Heat treatment involves subjecting the billets to specific temperatures and durations to achieve desired hardness, strength, and durability. This process can include steps such as quenching, tempering, and annealing, depending on the desired characteristics of the bearing. After heat treatment, the steel billets are ready for the final step in the bearing manufacturing process: assembly. The billets are inspected for any defects or imperfections and then assembled with other bearing components, such as inner and outer rings, rolling elements, and cages. These components are carefully matched and assembled to achieve the desired performance and load-carrying capacity of the bearing. In conclusion, steel billets play a crucial role in the manufacturing of bearings. They are initially forged into a rough bearing shape, then machined, heat-treated, and finally assembled with other components to create a high-quality bearing that can withstand various loads and provide smooth movement in a wide range of applications.

- Q: What are the different types of steel used in manufacturing steel billets?

- There are several different types of steel used in the manufacturing of steel billets. Some of the most common types include carbon steel, stainless steel, alloy steel, and tool steel. 1. Carbon Steel: This is the most commonly used type of steel for manufacturing steel billets. It contains a small amount of carbon, typically around 0.05% to 0.25%, which gives it its strength and durability. Carbon steel is versatile and can be used in a wide range of applications. 2. Stainless Steel: Stainless steel is known for its corrosion resistance and high strength. It contains chromium, which forms a protective oxide layer on the surface, preventing rust and corrosion. Stainless steel is often used in applications where resistance to moisture and chemicals is required, such as in the construction of bridges and buildings. 3. Alloy Steel: Alloy steel is made by adding various alloying elements to carbon steel, such as manganese, nickel, chromium, and molybdenum. These elements enhance the steel's properties, such as its strength, hardness, and resistance to wear and tear. Alloy steel is commonly used in the automotive and aerospace industries. 4. Tool Steel: Tool steel is specifically designed to have high hardness, abrasion resistance, and the ability to withstand high temperatures. It is often used in the production of cutting tools, molds, and dies. Tool steel is typically made with a combination of alloying elements, such as tungsten, vanadium, and cobalt. These are just a few examples of the different types of steel used in the manufacturing of steel billets. The selection of the specific type of steel depends on the desired properties and the intended application of the steel billets.

- Q: What are the different finishing processes used for steel billets?

- There are several different finishing processes used for steel billets to achieve the desired surface quality and dimensions. These processes include: 1. Hot rolling: This process involves passing the steel billets through a series of heated rollers to reduce their thickness and shape them into the desired profile. It can be used to produce a variety of finished products, such as bars, rods, and structural shapes. 2. Cold drawing: In this process, the steel billets are pulled through a series of dies at room temperature to reduce their cross-sectional area and improve their surface finish. Cold drawing is commonly used to produce high-quality steel bars and wires with precise dimensions and a smooth surface. 3. Peeling: Peeling is a machining process in which a thin layer of material is removed from the surface of the steel billets using a cutting tool. This process helps to improve the surface finish, remove any defects, and achieve tight dimensional tolerances. 4. Grinding: Grinding involves using an abrasive wheel or belt to remove material from the surface of the steel billets. It is commonly used to remove surface defects, such as scale and rust, and to achieve a smooth and uniform surface finish. 5. Polishing: Polishing is a finishing process that involves using abrasive materials, such as polishing compounds and buffing wheels, to create a smooth and reflective surface on the steel billets. It is often used to enhance the aesthetic appeal of the finished product and improve its resistance to corrosion. 6. Coating: Coating is a process in which a protective layer is applied to the surface of the steel billets to improve their resistance to corrosion and other environmental factors. Common coating methods include galvanizing, where a layer of zinc is applied to the surface, and painting, where a layer of paint or other protective material is applied. Overall, these finishing processes are essential in ensuring that steel billets meet the required specifications and standards for their intended applications. They help to improve the surface finish, dimensional accuracy, and overall quality of the finished steel products.

Send your message to us

Square Steel Billet, Square Bar, Prime Steel Billet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords