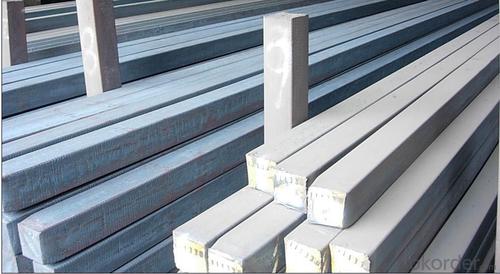

Prime square alloy steel billet 125mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 125mm Q235

Description of Prime square alloy steel billet 125mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime square alloy steel billet 125mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 125mm Q235

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

Specifications of Prime square alloy steel billet 125mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 125mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: What are the different quality standards for steel billets?

- There are several quality standards for steel billets, including ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), and EN (European Norm) standards. These standards define various parameters such as chemical composition, mechanical properties, and dimensional tolerances that steel billets must meet in order to ensure their quality and suitability for different applications.

- Q: Are steel billets used in the manufacturing of construction machinery?

- Yes, steel billets are commonly used in the manufacturing of construction machinery. Steel billets are semi-finished products that are used as raw materials in various industries, including construction machinery manufacturing. These billets are typically made from molten steel that is cast into a solid form and then further processed to shape and size. Due to their high strength, durability, and versatility, steel billets are ideal for constructing heavy-duty components and structures in construction machinery. They can be used to manufacture various parts such as chassis, frames, buckets, booms, and arms, among others. The use of steel billets ensures that construction machinery is capable of withstanding the demanding conditions and heavy loads commonly encountered in construction projects.

- Q: What are the different types of defects found in steel billets?

- Steel billets can commonly exhibit various types of defects. These defects may arise from the manufacturing process or external factors. A range of defects is often found in steel billets, including the following: 1. Surface defects: These defects are visible on the billet's surface and can comprise scale, scratches, cracks, or pits. Improper handling, inadequate cleaning, or excessive heat during manufacturing can lead to surface defects. 2. Internal defects: These defects are not apparent on the surface and can only be identified through non-destructive testing methods. Voids, inclusions, segregation, or non-uniform microstructures are examples of internal defects. They can impact the steel billet's mechanical properties and overall quality. 3. Decarburization: Exposure to high temperatures or oxygen can cause the surface layer of the billet to lose its carbon content, resulting in decarburization. This defect weakens the billet, reducing its strength and hardness. 4. Shrinkage cavities: When the steel billet solidifies and contracts unevenly, shrinkage cavities form. These cavities can compromise the mechanical properties and structural integrity of the billet. 5. Surface cracks: During the cooling and solidification process, thermal stresses can cause cracks to develop in the billet's surface. These cracks can extend into the interior, leading to additional defects and potential failure. 6. Segregation: Segregation refers to the uneven distribution of elements or impurities within the steel billet. This inconsistency can result in varying mechanical properties, reduced strength, and poor machinability. 7. Inclusions: Inclusions are foreign particles or impurities that become trapped within the steel billet during manufacturing. These inclusions can affect the mechanical properties and cause defects like porosity or brittleness. To ensure high-quality finished products, it is crucial to minimize and control these defects in steel billets. Implementing proper quality control measures, handling materials appropriately, and refining manufacturing processes can help reduce the occurrence of these defects and enhance the overall quality of steel billets.

- Q: How are steel billets used in the manufacturing of tools and equipment?

- Steel billets are an essential raw material used in the manufacturing of tools and equipment. These billets are semi-finished metal forms, typically in a rectangular or square shape, that are further processed to produce a wide range of products. To begin with, steel billets are heated and then subjected to a process called hot rolling. During this process, the billets are passed through a series of rollers, which gradually reduce their thickness and shape them into desired forms. This can include bars, rods, sheets, or even more complex shapes depending on the specific requirements of the tool or equipment being manufactured. Once the desired shape is achieved, the steel billets are further processed through various techniques such as forging, machining, and heat treatment. Forging involves applying pressure to shape the billets into specific tool components, while machining is used to refine the shape and dimensions of the parts. Heat treatment, on the other hand, helps to enhance the mechanical properties of the steel, making it stronger, more durable, and resistant to wear and tear. The resulting steel components are then assembled and integrated into the manufacturing of tools and equipment. These can include a wide range of products such as wrenches, hammers, drills, cutting tools, industrial machinery, and even large-scale equipment used in sectors like construction and manufacturing. Steel billets are preferred for tool and equipment manufacturing due to their excellent mechanical properties. Steel is known for its high strength, toughness, and durability, making it an ideal material for applications that require resistance to heavy loads, impact, and wear. Furthermore, steel can be easily machined, welded, and formed into various shapes, allowing manufacturers to create tools and equipment with intricate designs and precise dimensions. In summary, steel billets play a crucial role in the manufacturing of tools and equipment. Through the process of hot rolling, forging, machining, and heat treatment, steel billets are transformed into high-quality components that form the foundation of various tools and equipment. The versatility and superior mechanical properties of steel make it an indispensable material in the manufacturing industry.

- Q: What are the main factors affecting the quality of steel billets?

- There are several main factors that can significantly affect the quality of steel billets. These factors include the composition of the steel, the temperature and time of the heating process, the cooling rate, and the presence of impurities. Firstly, the composition of the steel plays a crucial role in determining its quality. The presence of certain elements such as carbon, manganese, and silicon can affect the mechanical properties of the steel, including its strength and hardness. The proper control and balance of these alloying elements are essential to ensure the desired quality of the steel billets. Secondly, the temperature and time of the heating process during the production of steel billets are critical factors. The heating process must be carefully controlled to achieve the optimal temperature for the desired transformation of the microstructure. Overheating or underheating can lead to the formation of undesirable phases or an inconsistent microstructure, which can negatively impact the quality of the billets. The cooling rate is another important factor affecting the quality of steel billets. The cooling process needs to be controlled to achieve the desired microstructure and mechanical properties. Too rapid cooling can result in the formation of brittle phases or residual stresses, while slow cooling can lead to coarse-grained structures with reduced strength. Furthermore, the presence of impurities in the steel can significantly affect its quality. Impurities such as sulfur, phosphorus, and non-metallic inclusions can decrease the mechanical properties and promote the formation of defects in the steel billets. Therefore, strict control of the raw materials and the implementation of effective refining techniques are necessary to minimize the presence of impurities. In conclusion, the main factors affecting the quality of steel billets are the composition of the steel, the temperature and time of the heating process, the cooling rate, and the presence of impurities. By carefully controlling and optimizing these factors, steel manufacturers can produce high-quality billets that meet the desired specifications and performance requirements.

- Q: What are the different forging processes for steel billets?

- Different forging processes can be used for steel billets, depending on the desired final product's shape and properties. Some of these processes include: 1. Open-Die Forging: Steel billets are placed between flat dies and compressed to shape them. The billet is not completely enclosed, allowing it to freely deform and flow. Open-die forging is commonly used for large and simple shapes like bars, shafts, and rings. 2. Closed-Die Forging: Also known as impression-die forging, this process involves using specially shaped dies that fully enclose the steel billet. The dies have cavities matching the desired final shape. When the billet is compressed between the dies, it takes the shape of the cavities, resulting in a precise and intricate final product. Closed-die forging is suitable for complex shapes like automotive components, aerospace parts, and tools. 3. Seamless Rolled Ring Forging: Steel billets are shaped into a ring blank and then subjected to intense pressure between two rotating dies. The dies gradually reduce the diameter of the ring blank, elongating and shaping it into the desired ring shape. Seamless rolled ring forging is commonly used for producing large and high-strength rings used in turbines, gears, and bearings. 4. Upset Forging: In this process, the steel billet is heated and placed between two dies. One die remains stationary while the other moves towards the billet, compressing it and causing radial spreading. Upset forging is commonly used for short-length parts like bolts, screws, and rivets. 5. Press Forging: A hydraulic or mechanical press is used to apply compressive forces to the steel billet, shaping it into the desired form. Press forging can be done with open or closed dies, depending on shape complexity. It is commonly used for producing components with high accuracy and intricate details like gears, engine parts, and hand tools. Each of these forging processes has its own advantages and limitations based on the specific requirements of the steel billet and the desired final product. Factors such as shape complexity, material properties, production volume, and cost considerations determine the choice of forging process.

- Q: How do steel billets contribute to the manufacturing of construction materials?

- Steel billets play a vital role in the manufacturing of construction materials. They serve as the raw material that is transformed into various steel products used in construction projects. Firstly, steel billets are the starting point for the production of different types of steel products such as bars, rods, beams, and sections. These products are essential components in the construction industry as they provide structural support and reinforcement. For example, steel bars are commonly used in the construction of reinforced concrete structures, providing strength and durability to the building. Furthermore, steel billets are also utilized in the manufacturing of pipes and tubes, which are crucial for plumbing, heating, ventilation, and air conditioning (HVAC) systems in buildings. These pipes and tubes ensure the efficient flow of water, gas, and air, contributing to the overall functionality and comfort of the structure. Moreover, steel billets are utilized in the production of steel sheets and plates, which are widely used in construction applications such as roofing, cladding, and flooring. Steel sheets and plates offer excellent strength, corrosion resistance, and aesthetic appeal. They are commonly used in high-rise buildings, warehouses, and industrial facilities. Additionally, steel billets are crucial in the production of prefabricated construction materials. Prefabrication involves the manufacturing of building components off-site, which are then transported and assembled on-site. Steel billets are used to create prefabricated steel frames, trusses, and panels, streamlining the construction process and reducing time and labor costs. In summary, steel billets are the foundation of the construction materials industry. They are transformed into various steel products that are essential for structural support, reinforcement, plumbing, HVAC systems, roofing, cladding, flooring, and prefabrication. The use of steel billets ensures the strength, durability, and functionality of construction materials, contributing significantly to the overall quality of construction projects.

- Q: How are steel billets used in the manufacturing of medical equipment?

- Steel billets are used in the manufacturing of medical equipment as a raw material that can be shaped and machined into various components such as surgical instruments, implants, and medical device casings. The high strength and durability of steel make it suitable for producing equipment that requires precision, reliability, and resistance to corrosion.

- Q: What are the different surface treatments for steel billets?

- Steel billets can undergo various surface treatments to enhance their performance and safeguard them against corrosion. Hot-dip galvanizing is a popular method, which involves immersing the billets in molten zinc to create a protective coating that acts as a barrier against moisture and corrosive elements. Electroplating offers another option, where a thin layer of metal like chromium or nickel is deposited onto the billet surface using an electric current. This not only provides corrosion resistance but also enhances the appearance of the billets. Painting or powder coating is a third approach, wherein a layer of paint or dry powder is applied to the billet surface. This forms a protective barrier, preventing moisture and corrosive substances from reaching the steel. Shot blasting or sandblasting can also be utilized for surface treatment. This technique involves propelling abrasive particles at high speeds onto the billet surface to eliminate impurities and scale, resulting in a clean and smooth finish. Lastly, chemical treatments like phosphating are available. Phosphating involves immersing the steel in a phosphoric acid solution, forming a protective phosphate coating that improves corrosion resistance and promotes paint adhesion. Ultimately, the choice of surface treatment for steel billets depends on the specific requirements of the application and the desired level of protection against corrosion and environmental factors.

- Q: What are the different types of steel billet forging machines?

- There are several different types of steel billet forging machines, including mechanical presses, hydraulic presses, screw presses, and hammer forging machines. Each type of machine has its own unique characteristics and capabilities, allowing for the efficient and precise forging of steel billets into desired shapes and sizes.

Send your message to us

Prime square alloy steel billet 125mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords