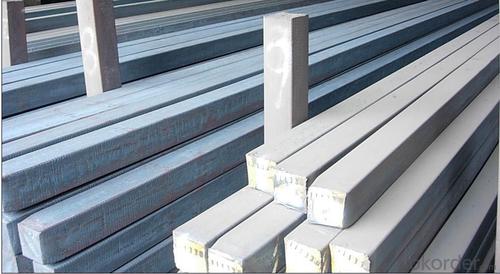

Prime square alloy steel billet 110mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 105mm Q235

Description of Prime square alloy steel billet 105mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime square alloy steel billet 105mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 105mm Q235

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Specifications of Prime square alloy steel billet 105mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 105mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: What are the potential applications of steel billets in the automotive aftermarket?

- Steel billets have a wide range of potential applications in the automotive aftermarket. These applications can be primarily attributed to the strength, durability, and versatility of steel as a material. Firstly, steel billets can be used in the production of various automotive parts, such as engine components, transmission parts, suspension systems, and chassis components. Due to its high tensile strength and resistance to wear and tear, steel billets can provide the necessary structural integrity and longevity required in these critical automotive components. Additionally, steel billets can be used in the manufacturing of customized or aftermarket modifications for vehicles. These modifications can include performance upgrades, such as engine tuning, exhaust systems, and suspension modifications. Steel billets can be machined and formed into the desired shapes and sizes, allowing for precise customization and improved performance. Furthermore, steel billets can be utilized in the production of automotive tools and equipment used in the aftermarket. These tools can include jacks, stands, wrenches, and other specialized equipment required for repairs, maintenance, and modifications. The use of steel billets ensures that these tools are strong, durable, and capable of withstanding the demanding conditions of the automotive industry. Moreover, steel billets can be employed in the manufacturing of aftermarket body parts and accessories. These can range from exterior components such as bumpers, grilles, and fenders, to interior accessories like shift knobs, pedals, and trim pieces. Steel billets can be shaped, welded, and finished to meet the desired specifications and aesthetics of the vehicle owner, providing a wide range of options for customization. Overall, the potential applications of steel billets in the automotive aftermarket are vast and diverse. From critical engine components to performance upgrades, tools, and body modifications, steel billets offer the necessary strength, durability, and versatility required in the automotive industry.

- Q: What are the dimensions of a typical steel billet?

- The dimensions of a typical steel billet can vary depending on its intended use and the specific manufacturing process. However, generally speaking, steel billets usually have a rectangular shape with widths ranging from 100mm to 300mm, heights ranging from 100mm to 400mm, and lengths ranging from 6m to 12m. These dimensions allow for easy handling and transportation, as well as flexibility in shaping and forming the steel billet into various end products like bars, rods, or sheets. It's worth noting that these dimensions are not set in stone and can be tailored to meet the specific requirements of the production process or the customer's preferences.

- Q: Can steel billets be forged into complex shapes?

- Complex shapes can be achieved by forging steel billets. The process involves heating the billet to a specific temperature, usually above its recrystallization temperature, and then applying pressure to shape it. Various forging techniques like open die, closed die, or impression die forging can be used. Steel is highly malleable and can be easily shaped and deformed under heat and pressure. This property allows steel billets to be forged into intricate shapes like gears, turbine blades, automotive parts, and other components used in different industries. Forging not only shapes the billet but also enhances its mechanical properties, making it stronger and more durable. The resulting forged steel has a refined grain structure, improving its toughness, resistance to fatigue, and resistance to cracking. However, forging complex shapes from steel billets requires skilled craftsmanship and specialized equipment. The process may involve multiple steps like pre-forming, rough forging, and finish forging to achieve the desired shape and dimensions. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are often used to optimize the forging process and ensure precision and accuracy. To sum up, steel billets can be forged into intricate shapes. Through forging, the malleability of steel is harnessed to create components with improved mechanical properties.

- Q: What is the lifespan of a steel billet?

- The lifespan of a steel billet is indefinite as long as it is properly stored and maintained, making it a durable and long-lasting material.

- Q: What are the main applications of steel billets in the aerospace industry?

- Steel billets are an essential component in the aerospace industry, finding numerous applications due to their exceptional strength, durability, and thermal properties. One of the main applications of steel billets in the aerospace industry is in the production of aircraft structural components. These billets are commonly used to manufacture critical parts such as landing gear, wing spars, fuselage frames, and engine mounts, providing the necessary strength and stability required for safe and efficient flight. Moreover, steel billets are also utilized in the aerospace industry for the production of engine components. Due to their high heat resistance and ability to withstand extreme temperatures, steel billets are used to manufacture turbine blades, shafts, and other critical parts within jet engines. These components must withstand intense heat and pressure, and steel billets offer the necessary properties to ensure reliable and efficient engine performance. Additionally, steel billets play a crucial role in the aerospace industry through their application in the production of fasteners and connectors. These components are vital for securely joining various parts of an aircraft, ensuring structural integrity and safety during flight. Steel billets are used to manufacture high-strength bolts, screws, and other fasteners, providing the necessary strength and reliability for aerospace applications. Furthermore, steel billets are often employed in the aerospace industry for the production of hydraulic and pneumatic systems. These systems are responsible for controlling the aircraft's movement, landing gear operation, and other crucial functions. Steel billets are used to manufacture hydraulic cylinders, valves, and tubes, offering the necessary strength and resistance to withstand high pressures and extreme conditions. In summary, the main applications of steel billets in the aerospace industry include aircraft structural components, engine parts, fasteners and connectors, as well as hydraulic and pneumatic systems. Their exceptional strength, durability, and thermal properties make steel billets indispensable for ensuring the safety, efficiency, and reliability of aerospace operations.

- Q: How are steel billets used in the manufacturing of springs?

- To produce springs, it is essential to utilize steel billets as they provide the necessary raw material for the manufacturing process. The billets, typically made from high-quality steel, are forged to create springs. To begin the process, the billets are heated to a specific temperature, making them malleable. Once heated, the billets are shaped into the desired form using methods like hot rolling or extrusion. After shaping, the billets undergo further processing to enhance their mechanical properties. This involves heat treatment processes like quenching and tempering to improve the steel's hardness, strength, and durability. The specific heat treatment process chosen depends on the desired characteristics of the spring. Once the billets are shaped and heat-treated, they are ready for transformation into springs. Generally, the billets are cut into smaller lengths and then machined or formed into the specific shape and size required for the spring. This can be achieved through methods such as coiling, bending, or stamping. The final stage of the manufacturing process involves finishing the springs. This can include grinding or polishing to ensure a smooth surface and eliminate any imperfections. Additionally, coatings or platings may be applied to enhance the springs' corrosion resistance or aesthetic appearance. In conclusion, steel billets play a vital role in the manufacturing of springs. They serve as the raw material, undergo various shaping and heat treatment processes, and are ultimately transformed into the desired form of the spring. By utilizing high-quality steel billets, the resulting springs possess the necessary strength, durability, and performance characteristics required for their intended applications.

- Q: How are steel billets used in the manufacturing of tools?

- Steel billets are used in the manufacturing of tools as they serve as the raw material for tool production. A steel billet is a semi-finished product that is typically a long, solid piece of steel with a square or rectangular cross-section. These billets are produced through a process called steelmaking, where iron ore is melted and converted into steel. To manufacture tools, the steel billets are first heated to a specific temperature, known as forging temperature. At this temperature, the steel becomes malleable and can be easily shaped and formed. The billets are then subjected to various forging techniques, such as hammering, pressing, or rolling, to shape them into the desired tool form. Once the billets are forged into the desired shape, they are further processed through machining operations like milling, drilling, grinding, or turning to achieve the required dimensions and surface finish. This stage involves removing excess material and refining the tool's shape and features. After the machining process, the tools are heat-treated to enhance their mechanical properties. Heat treatment involves subjecting the tools to specific heating and cooling cycles to alter their hardness, toughness, and wear resistance. This step is crucial as it ensures the tools can withstand the demanding conditions they will be exposed to during their use. Finally, the tools are finished and coated to provide protection against corrosion and improve their appearance. This can involve processes such as sandblasting, polishing, and applying protective coatings like chrome plating or powder coating. In summary, steel billets play a crucial role in the manufacturing of tools. They provide the raw material from which tools are forged, machined, heat-treated, and finished. The properties of the steel billets, such as their composition and metallurgical characteristics, contribute to the final quality, strength, and durability of the tools produced.

- Q: What are the different sizes of steel billets?

- Steel billets come in a variety of sizes, depending on their intended use and the specific requirements of the manufacturing process. The most common sizes of steel billets range from 100mm to 200mm square in cross-section. However, larger billets can also be produced, with sizes exceeding 300mm square. These larger billets are often used for heavy-duty applications or in industries that require larger quantities of steel, such as construction or shipbuilding. Additionally, steel billets can also be produced in round or rectangular shapes, depending on the requirements of the final product. The size of the steel billet is an important consideration in the manufacturing process, as it determines the amount of material that can be used and the level of precision that can be achieved during the shaping and forming processes.

- Q: What are the different methods used for heating steel billets?

- There are several methods used for heating steel billets including induction heating, flame heating, and electric resistance heating.

- Q: How are steel billets inspected for quality?

- Steel billets are typically inspected for quality using various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and dye penetrant testing. These tests help identify any surface defects, cracks, or internal flaws in the billets, ensuring that they meet the required quality standards before further processing.

Send your message to us

Prime square alloy steel billet 110mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords