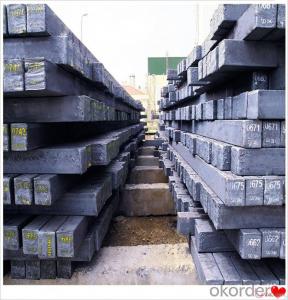

Steel Billet Square with High Quality and Competitive Prices for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Billet Square with High Quality and Competitive Prices for Sale with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Billet Square with High Quality and Competitive Prices for Sale are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Billet Square with High Quality and Competitive Prices for Sale are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Packaging & Delivery:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the common defects found in steel billets?

- Some common defects found in steel billets include surface cracks, internal voids or inclusions, improper segregation of alloying elements, and uneven grain structure. Other defects may include surface pitting, surface decarburization, or dimensional inconsistencies. These defects can affect the quality and strength of the steel billet, and may require further processing or corrective measures before the billet can be used for manufacturing purposes.

- Q: How are steel billets used in the manufacturing of kitchen appliances?

- Kitchen appliances require steel billets as they possess versatile properties and can be molded into different shapes and sizes. These billets, typically made from low carbon steel, act as the raw material for manufacturing kitchen appliances like stoves, ovens, refrigerators, and dishwashers. The production process starts by heating the steel billets to a high temperature, known as annealing, to enhance their formability and ductility. Once the desired temperature is achieved, the billets are passed through rolling mills to reduce their size and shape them accordingly. This hot rolling process forms steel sheets or plates, which can be further processed. Next, these steel sheets or plates are cut, bent, and formed into various components of kitchen appliances. For instance, the body of a refrigerator or oven is often made by shaping and welding steel sheets together to create a strong and durable structure. Similarly, the burners and grates of a stove are typically cast and machined from steel billets to acquire the desired shape. The use of steel billets in manufacturing kitchen appliances offers numerous advantages. Steel is renowned for its strength, durability, and resistance to corrosion, making it an excellent choice for appliances that endure frequent use and exposure to moisture. Additionally, steel is easy to clean and maintain, ensuring the longevity and hygiene of the appliances. Moreover, steel is a cost-effective material for kitchen appliance manufacturing. Its widespread availability and comparatively low production costs contribute to making kitchen appliances more affordable for consumers. In conclusion, steel billets play a vital role in the production of kitchen appliances by providing a versatile and cost-effective material that can be shaped, formed, and assembled into different components. Their strength, durability, and resistance to corrosion make steel billets an ideal choice for manufacturing high-quality kitchen appliances that meet the demands of modern households.

- Q: What are steel billets?

- Steel billets are semi-finished metal products that are typically rectangular in shape and made from molten steel. They serve as raw material for further processing and are commonly used in the production of bars, rods, and wire products.

- Q: Billet heating furnace billet temperature reached, steel will be adhesion

- There are a lot of billet heating furnace manufacturers, not just look at the price and go blind choice, billet heating furnace selection properly, will directly affect the day after work is carried out properly, choose cost-effective equipment is the first choice for users, recommended to look at the video consultation.

- Q: What is the global production and consumption of steel billets?

- Steel billets play a crucial role in the worldwide construction and manufacturing sectors, with their production and consumption being of great significance. When it comes to manufacturing, several countries are major players in the production of steel billets. China, the largest producer of steel globally, contributes significantly to the global steel billet production. Other notable producers include India, Japan, Russia, the United States, and Turkey. These countries have well-established steel industries and infrastructure to support large-scale production. The consumption of steel billets is driven by the demand for steel products in various sectors. The construction and infrastructure development sectors are the primary drivers, as steel is widely used in the construction of buildings, bridges, roads, and other structures. The automotive industry is also a major consumer, utilizing steel billets for manufacturing automobile parts and components. Providing an exact figure for global steel billet production and consumption is challenging due to the ever-changing market dynamics and varying industry reports. However, it is estimated that global steel production exceeded 1.8 billion metric tons in 2020, with a significant portion of this production in the form of steel billets. The consumption of steel billets is closely linked to overall steel demand, which is influenced by economic growth, infrastructure development, industrial activity, and construction projects worldwide. In conclusion, the global production and consumption of steel billets are of great significance, highlighting the importance of steel as a vital material in various industries. The continuous growth in infrastructure development and industrialization globally is expected to further drive the production and consumption of steel billets in the years to come.

- Q: What are the different surface finishes available for stainless steel billets?

- Stainless steel billets offer a range of surface finishes to meet diverse aesthetic and functional needs. Here are some commonly used finishes: 1. The mill finish is the standard produced by the steel mill during manufacturing. It presents a dull appearance with visible oxidation marks, and its smoothness may vary. 2. Hot rolling involves heating the billet and rolling it through rollers to achieve a rougher surface with visible scale and an orange peel texture. 3. Cold rolling reduces the thickness of the billet and enhances surface smoothness, resulting in a slightly reflective finish suitable for applications requiring smooth surfaces. 4. The brushed finish, also known as satin finish, entails mechanically brushing the billet with abrasive materials to create a consistent linear pattern and a matte appearance. 5. Polishing the billet with abrasives produces a smooth and reflective surface, with varying levels of gloss, ranging from low-gloss satin to mirror-like high reflectivity. 6. Bead blasting involves bombarding the billet with tiny glass or ceramic beads at high pressure to create a uniform matte texture, often used for architectural and decorative purposes. 7. Electropolishing achieves a smooth and reflective surface with enhanced corrosion resistance by immersing the billet in an electrolyte bath and applying an electric current to remove a thin layer of material. These examples illustrate the variety of surface finishes available for stainless steel billets. Each finish possesses unique characteristics and is selected based on specific requirements, such as aesthetics, corrosion resistance, and ease of cleaning.

- Q: How do steel billets contribute to the overall cost-effectiveness of a project?

- There are several ways in which steel billets contribute to the cost-effectiveness of a project. To begin with, steel billets serve as the initial material for various steel products, such as beams, bars, and sheets. Manufacturers can produce these products in a cost-effective manner by utilizing steel billets, which are usually less expensive than finished steel products. Furthermore, the use of steel billets allows for the efficient utilization of resources. They can be easily melted down and shaped into different forms and sizes, thereby reducing waste during the production process. This adaptability diminishes the amount of raw material required, resulting in cost savings. In addition, steel billets possess exceptional strength and durability characteristics. By incorporating steel billets into construction projects, engineers can ensure the solidity and longevity of the structures. This helps to decrease maintenance and repair expenses over time, ultimately enhancing the project's cost-effectiveness. Moreover, steel billets are readily available in the market, making them a cost-effective option for projects with tight schedules. Manufacturers can easily procure steel billets from various suppliers, ensuring a consistent supply of material for the project. Lastly, steel billets contribute to cost-effectiveness through their recyclability. Steel is one of the most widely recycled materials globally, and the use of recycled steel billets can significantly reduce production costs. The recycling of steel billets also aids in minimizing the environmental impact of a project, making it a more sustainable and cost-effective choice. All in all, steel billets play a crucial role in enhancing the cost-effectiveness of a project by providing an economical starting material, reducing waste, ensuring durability, facilitating availability, and promoting recycling.

- Q: What are the main surface finishes available for steel billets?

- The main surface finishes available for steel billets include hot rolled, cold rolled, and coated finishes.

- Q: What are the potential applications of steel billets in the food and beverage aftermarket?

- Steel billets have a wide range of potential applications in the food and beverage aftermarket. One potential application is in the production of food processing equipment. Steel billets can be used to manufacture machinery and equipment that is used in food processing plants, such as conveyor belts, food mixers, and cutting tools. The durability and strength of steel make it a suitable material for these applications, as it can withstand the rigors of heavy use and maintain its integrity even in harsh conditions. Another potential application of steel billets in the food and beverage aftermarket is in the construction of storage tanks and containers. Steel is known for its corrosion resistance, making it ideal for storing various food and beverage products. Steel billets can be used to manufacture tanks and containers that can safely store liquids such as water, juices, and alcoholic beverages. These steel tanks can also be insulated to ensure temperature control, which is crucial in preserving the quality of perishable products. Furthermore, steel billets can be used in the production of kitchen equipment and utensils. Steel is a hygienic material that is easy to clean and maintain, making it suitable for use in commercial kitchens and food preparation areas. Steel billets can be shaped into various kitchen utensils such as knives, pans, and cooking pots, which are essential tools in the food and beverage industry. Steel utensils are known for their durability and heat conductivity, which ensures even cooking and efficient food preparation. Overall, the potential applications of steel billets in the food and beverage aftermarket are vast. From food processing equipment to storage tanks and kitchen utensils, steel billets provide a reliable and versatile material for various industries within the food and beverage sector. Its strength, durability, and hygienic properties make it a valuable resource in ensuring the safe and efficient production, storage, and preparation of food and beverages.

- Q: What is the purpose of using steel billets in manufacturing?

- The aim of utilizing steel billets in the manufacturing sector is to produce a dependable and adaptable raw material for diverse industrial uses. These semi-finished goods, known as steel billets, are created through the continuous casting or hot rolling methods. These solid rectangular or square-shaped steel bars act as the foundation for manufacturing a wide array of steel products. One of the main objectives of using steel billets is to provide a reliable and high-quality material with specific mechanical properties. Steel, which is composed of iron and carbon, can be customized by adjusting the carbon content, alloying elements, and heat treatment processes. By controlling these variables during the production of steel billets, manufacturers can ensure that the resulting steel products possess desired characteristics such as strength, hardness, ductility, and resistance to corrosion. Moreover, steel billets enable manufacturers to efficiently shape and form the desired end products. They can undergo further processing using techniques like hot rolling, forging, extrusion, or machining to create different shapes, sizes, and profiles. Steel billets serve as the starting point for the production of a wide range of steel products, including bars, rods, tubes, wire, structural shapes, and even intricate components for machinery, automobiles, construction, and infrastructure projects. Additionally, the utilization of steel billets in the manufacturing sector offers numerous advantages. Steel is renowned for its outstanding strength, durability, and versatility, making it an ideal material for various applications. Steel billets provide a cost-effective option for manufacturers as they can be mass-produced and easily transformed into different forms. Furthermore, steel is highly recyclable, ensuring a sustainable and environmentally friendly manufacturing process. In conclusion, the purpose of incorporating steel billets in manufacturing is to provide a consistent and high-quality raw material that can be shaped and processed into a variety of steel products. Steel billets offer the flexibility, strength, and durability required for a wide range of industrial applications, making them an indispensable component in the manufacturing industry.

Send your message to us

Steel Billet Square with High Quality and Competitive Prices for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords