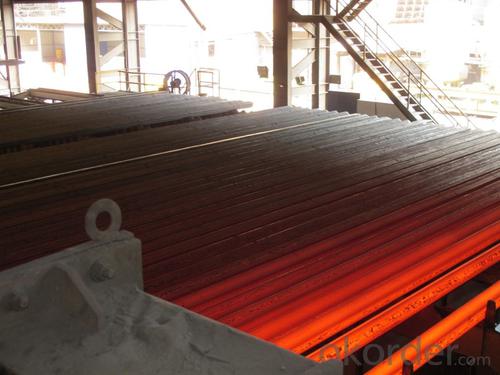

Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets used in the manufacturing of power plant equipment?

- Steel billets are an essential component in the manufacturing of power plant equipment due to their superior strength and durability. These billets serve as the raw material that is shaped and formed into various parts and components required for power plant machinery. One of the key applications of steel billets in power plant equipment manufacturing is in the production of turbine blades. These blades are subjected to high temperatures, extreme pressures, and rotational forces. Steel billets are carefully selected to possess the necessary mechanical properties, such as high tensile strength and resistance to corrosion and fatigue, ensuring the blades can withstand the demanding operating conditions. Moreover, steel billets are also used in the production of generator rotors and stators. These components are responsible for converting mechanical energy into electrical energy. The strength and stability of steel billets allow them to withstand the intense magnetic fields and rotational forces generated by the generator, ensuring reliable and efficient power generation. Furthermore, steel billets are utilized in the manufacturing of boilers and pressure vessels, which are crucial for the power generation process. These vessels are subjected to high pressures and temperatures, and steel billets with excellent heat resistance and pressure containment properties are employed to ensure the safety and reliability of the power plant equipment. In summary, steel billets are integral to the manufacturing of power plant equipment due to their superior strength, durability, and resistance to extreme conditions. Whether it is for turbine blades, generator components, or pressure vessels, steel billets play a crucial role in ensuring the reliable and efficient operation of power plants.

- Q: What are the different surface treatments for improved wear resistance in steel billets?

- There are several surface treatments available to improve wear resistance in steel billets. These treatments are designed to enhance the durability and longevity of the steel, making it more resistant to wear and tear. One commonly used surface treatment is case hardening. This process involves heating the steel billets to a high temperature and then rapidly cooling them in a quenching medium, such as oil or water. This creates a hard outer layer on the steel, known as a case, while maintaining a relatively softer core. The hardened case provides excellent wear resistance, while the softer core maintains toughness and ductility. Another surface treatment for improved wear resistance is nitriding. This process involves introducing nitrogen into the surface of the steel billets, typically through a gas or plasma-based process. The nitrogen diffuses into the steel, forming a hard nitride layer on the surface. This nitride layer significantly increases the hardness and wear resistance of the steel, making it suitable for applications where high wear resistance is required. A third surface treatment option is hard chrome plating. In this process, a layer of chromium is electroplated onto the surface of the steel billets. The chromium layer provides excellent wear resistance and corrosion resistance, making it ideal for applications where the steel will be exposed to harsh environments or abrasive materials. Additionally, physical vapor deposition (PVD) and chemical vapor deposition (CVD) are advanced surface treatment techniques that can be used to improve wear resistance in steel billets. These processes involve depositing a thin film of a wear-resistant material, such as titanium nitride or diamond-like carbon, onto the surface of the steel. These thin films provide a hard, low-friction surface that enhances wear resistance and reduces frictional losses. Overall, these surface treatments offer a range of options for improving wear resistance in steel billets. The choice of treatment depends on factors such as the specific application requirements, the desired level of wear resistance, and the budget constraints. Consulting with a materials expert or a surface treatment specialist can help determine the most suitable treatment for a particular steel billet application.

- Q: Can steel billets be used for making musical instruments?

- Musical instruments can indeed be crafted from steel billets. Although conventional instruments are typically fashioned from wood or brass, steel offers a distinctive and contemporary alternative. The strength and durability of steel render it well-suited for certain instruments, including steel drums and steel guitars. Moreover, steel's adaptability permits the formation of intricate designs and shapes, resulting in a broad spectrum of sounds. Nevertheless, it is crucial to acknowledge that the specific attributes and properties of the steel utilized, such as its composition and thickness, will heavily influence the instrument's sound and quality. Therefore, meticulous consideration and experimentation may prove necessary in order to achieve the desired musical tones and effects when employing steel billets for instrument production.

- Q: How are steel billets used in the manufacturing of springs?

- To produce springs, it is essential to utilize steel billets as they provide the necessary raw material for the manufacturing process. The billets, typically made from high-quality steel, are forged to create springs. To begin the process, the billets are heated to a specific temperature, making them malleable. Once heated, the billets are shaped into the desired form using methods like hot rolling or extrusion. After shaping, the billets undergo further processing to enhance their mechanical properties. This involves heat treatment processes like quenching and tempering to improve the steel's hardness, strength, and durability. The specific heat treatment process chosen depends on the desired characteristics of the spring. Once the billets are shaped and heat-treated, they are ready for transformation into springs. Generally, the billets are cut into smaller lengths and then machined or formed into the specific shape and size required for the spring. This can be achieved through methods such as coiling, bending, or stamping. The final stage of the manufacturing process involves finishing the springs. This can include grinding or polishing to ensure a smooth surface and eliminate any imperfections. Additionally, coatings or platings may be applied to enhance the springs' corrosion resistance or aesthetic appearance. In conclusion, steel billets play a vital role in the manufacturing of springs. They serve as the raw material, undergo various shaping and heat treatment processes, and are ultimately transformed into the desired form of the spring. By utilizing high-quality steel billets, the resulting springs possess the necessary strength, durability, and performance characteristics required for their intended applications.

- Q: Can steel billets be used in the production of aerospace components?

- Yes, steel billets can be used in the production of aerospace components. Steel billets are often used as raw material for forging processes, which can be used to manufacture various aerospace components such as landing gears, engine parts, and structural components.

- Q: How are steel billets used in the production of crankshafts?

- Steel billets are used in the production of crankshafts as they serve as the raw material that is shaped and machined to form the main body of the crankshaft. These billets are heated, forged, and then machined to create the precise shape and dimensions required for the crankshaft. This process ensures the strength, durability, and performance of the crankshaft in engines.

- Q: What is the cost of steel billets?

- The cost of steel billets can vary depending on factors such as market conditions, demand, and the specific type and quality of the billets. It is recommended to consult with a steel supplier or check current market prices for accurate and up-to-date information on the cost of steel billets.

- Q: How are steel billets inspected before they are used in production?

- Before being used in production, steel billets undergo a thorough inspection to ensure their quality and adherence to required specifications. The inspection process involves several key steps. Firstly, a visual inspection is conducted to examine the billets' surface for any defects such as cracks, seams, or deformities. Any irregularities can indicate potential weaknesses or problems that may affect performance during production. Secondly, dimensional inspection is performed to verify the billets' size, length, width, and other critical dimensions. This is crucial to ensure that the billets meet the precise requirements of the production process and can be seamlessly integrated into manufacturing operations. Thirdly, ultrasonic testing is often used to detect any internal defects or discontinuities within the billets. Ultrasonic waves are passed through the billet, and reflections or echoes are analyzed to identify any flaws such as voids, inclusions, or cracks that may compromise the billets' structural integrity. Moreover, magnetic particle inspection may be carried out to identify surface or near-surface defects that are not visible to the naked eye. This technique involves applying magnetic particles to the billet's surface and detecting any magnetic leakage caused by defects through the use of magnetic fields. Additionally, chemical analysis is frequently performed to ensure that the steel billets have the desired chemical composition. This involves taking samples from the billets and subjecting them to various tests to determine the percentages of different elements present. This analysis guarantees that the billets possess the necessary chemical properties for the intended application. In conclusion, steel billets undergo a comprehensive inspection process that includes visual examination, dimensional verification, ultrasonic testing, magnetic particle inspection, and chemical analysis. This multi-faceted approach ensures that the billets meet the required quality standards and are suitable for use in production, minimizing the risk of any performance issues or failures during manufacturing processes.

- Q: What are the different types of mechanical property testing methods for steel billets?

- Some different types of mechanical property testing methods for steel billets include tensile testing, hardness testing, impact testing, and fatigue testing. Tensile testing measures the strength and ductility of the material by applying a pulling force until it breaks. Hardness testing measures the resistance of the material to penetration or indentation. Impact testing evaluates the material's ability to absorb energy under high rates of loading. Fatigue testing assesses the material's resistance to failure under cyclic loading conditions.

- Q: How do steel billets contribute to the manufacturing of industrial machinery?

- The manufacturing of industrial machinery heavily relies on steel billets, which are semi-finished steel products molded into specific shapes and sizes. These billets serve as the raw material for producing various components and parts used in industrial machinery. To begin with, steel billets provide the necessary strength and durability required by industrial machinery. The high tensile strength and toughness of steel make it an ideal choice for withstanding heavy loads, vibrations, and extreme conditions that machinery often faces. By utilizing steel billets, manufacturers can ensure that the machinery they produce is capable of enduring these demanding conditions, thus increasing its reliability and longevity. Additionally, steel billets can be easily molded and shaped into different forms, allowing for the production of intricate and complex components. Precision-engineered parts tailored to specific functions and applications are often necessary for industrial machinery. Steel billets can be cast or forged into these intricate shapes, guaranteeing that the machinery operates with optimal efficiency and accuracy. Furthermore, steel billets possess excellent machinability, meaning they can be easily cut, drilled, and shaped using various machining techniques. This capability enables the creation of intricate details and tolerances required for the precise functioning of industrial machinery. The ability to machine steel billets with precision grants manufacturers the opportunity to produce components that fit together seamlessly, minimizing any potential performance issues. Moreover, steel billets offer a cost-effective solution for manufacturing industrial machinery. Steel is readily available and relatively inexpensive compared to other materials. Its superior strength-to-weight ratio also allows manufacturers to design lighter machinery without compromising its structural integrity. This reduction in manufacturing costs also makes the machinery more portable and easier to transport. Furthermore, steel billets provide excellent corrosion resistance, which is vital for industrial machinery operating in harsh environments. The protective oxide layer that forms on the surface of steel billets helps prevent rust and corrosion, ensuring that the machinery remains in optimal working condition even in challenging situations. In conclusion, the strength, durability, machinability, cost-effectiveness, and corrosion resistance offered by steel billets make them essential in the manufacturing of industrial machinery. These properties enable manufacturers to produce reliable, precise, and long-lasting machinery capable of withstanding demanding industrial applications.

Send your message to us

Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords