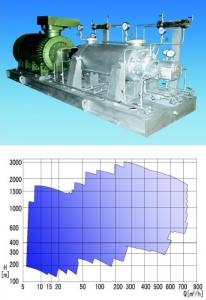

Horizontal Mixed Flow Pump HW

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Horizontal Mixed Flow Pump Product description

Axial-flow pumps are modern products successfully designed through adopting foreign modern technology. The new pumps’ capacity are 20% larger than the old ones. The efficiency is 3%-5% higher than the old ones. QZ series pump with adjustable impellers has the advantages of large capacity, broad head, high efficiency, wide application and so on. Pump station is small in scale, the construction is simple and the investment is greatly decreased. This can save 30%-40% for the building cost. It is easy to install,maintain and repair this kind of pump. Low noise,long life.

Horizontal Mixed Flow Pump Application

Axial-flow pump is applicable for water supply in cities, diversion works, sewage drainage system, sewage disposal project.

Horizontal Mixed Flow Pump Technical Data:

Flow rate: up to 20 m³/h

Head: up to 20 m

Speed: max rpm

Temperature: max °C

Casing pressure: up to MPa

Shaft seal: mechanical sealing

Material: nodular iron, stainless steel, duplex

- Q: My 2001 300M is behaving oddly. Occasionally it will gradually overheat after I have driven around for 15 or so minutes. Yes, occasionally. I took it to my mechanic who changed the thermostat and hoses. I then drove it on a trip on the interstate and over a mountain (140 miles ) It was fine with no signs of overheating. Then the next day when I drove to work in the city, the stop and go traffic had it overheating near the end of the trip. I've been able to keep it from going in the red by using the heater. After this happened most of the days, but not all, I took it back to the shop. He reported that the fans were working correctly and the only thing he could come up with is a weak water pump. He stated that when it did get hot, he was able to bring the temp down just by rev'ing the engine a little.Does that sound right? Any other ideas and how to test?

- The only reason to replace a water-pump on such a new car is if the weep-hole on the bottom of the water-pump in-put shaft casting is leaking. If your upper radiator hose if hot when the dash temperature reached 195 degree's there is nothing wrong with the water-pump. Cooling systems plug when brand X antifreeze is mixed with the standard equipment, long life type. *Did your mechanic do an inexpensive *cooling system pressure test to look for external and internal coolant leaks? Is the radiator filled to the very top when the engine is stone cold? Is the plastic coolant recovery bottle at least 3/4 full when the radiator cap has been removed? Have you checked to see of the electric cooling fans are operating behind the radiator when the dash temperature reaches 205 degrees? It's less expensive to change the thermostat and radiator pressure cap than a non-leaking water-pump. An 11 year old car is do to have the cooling system drained flushed and *cleaned before having Fresh factory recommended ZEREX G-05 antifreeze added.

- Q: ok so im wondering if there is a water pump out there i can buy that automatically turns on when i turn the tap on. i looking for something thats strong enough to pump enough water to more than one taps at a time i.e kitchen tap, bathroom etc.

- Lots of house booster systems available. Just ask.

- Q: I have a new water pump with its new gasket to be installed tomorrow. Do I still need to apply a gasket sealer (blue RTV silicone) on the gasket itself? If I do, do I need to apply it on both sides of the gasket? Thank you.

- Yes But not both sides Apply small dabs a couple of inches apart on the face of the water pump than carefully spread it out try not to get any inside the pump then place the gasket on line up holes the sealer will hold it in place

- Q: My water pump is starting to leak. The shops are quoting $250- $300 to replace but I can buy a water pump at the auto parts store and install myself for less than $100 but I don't know what all is involved with this repair or if I should try (my only experience with car repair up to now is recently replacing the alternator). If anyone has done this please let me know what you think. thanks

- if you have the right tools it not to hard make sure the old gasket is clean off the engine before installing the new pump use a light coat of gasket sealer with it

- Q: and how do I get it to work 24 hours a day?and on the pump there is written: 2 A, and on another part: 220-240 Vdoes that mean its wattage is 440-480Watt?

- Hey Don ..did you mean consecutive hours..if so. Here is how to do it..If there is fluid to be pumped there is sometimes a controller that will ask the pump to stop when it reaches low level . And again ON when it senses high level. Find this device, if one exists and either defeat it mechanically or wire around it electrically.Either is pretty simple. NOW that i have told you how to get it to run all the time. I though I might mention a timer..A timer, in series with your pump, will cut it off and give the liquid level a chance to rise as well. Timers can be defeated the same as all other protective devices,, My question is Are you sure this is what you want to do ? The plug on the end of the cord ,it must be a small pump if only 2 amps, should be your only control .If it has an auto off feature it's there to save your pump from burning the barn down ,so to speak, Why not take another look at your application. if you do have an endless fluid supply ,like a closed loop trickling fountain, remember those evaporate if make up water is not added. Sometimes though you need a pump to run 24-7 in which case just fool the controller..Of course the human is the true controller... :) Well I have armed you with enough info to get by on this please do so safely. From the E...

- Q: Installation position of check valve for water pump

- Check valves are generally installed at the pump outlet and exit control valve position. Self suction pump check valve installed in front of the pump, suction port better!Ordinary centrifugal pump check valve flange from the pump outlet flange is generally 300mm-500mm, its purpose is: when the pump is stopped, to prevent backflow of water to the pump body in the pipeline, resulting in the impeller reversal (generally positive rotation is more impeller impeller and shaft tight) that damage the impeller and pump head. Therefore, the height can not be too high, too high, there are too many water reflux, the consequences can be imagined.But there are self suction pumps, self suction pumps, check valves, flanges, pumps from the body, the outlet flange generally 1 meters to 1.5 meters.This is determined by the structure and working conditions of the self-priming pump. Self suction pump start, the pump is a gas at first, the main purpose is to exhaust the rotation of the impeller, will also play out some of the water, this time need to exhaust gas, water will need to return, if the valve is installed in the 300mm-500mm, then a lot of water can not return to the pump body (can also cause check valve is closed), effect of self suction pump work.Self suction pump check valve installed in the suction port of the pump better, this is not upstairs nine, brother said, must be installed in the export, this is wrong. Installed in the inlet of the purpose: it is time to stop the pump, there is generally no reversal of pump impeller, but to prevent the pipeline inside emptying (fluid inside the pipe can be in pipe) is beneficial to the self suction pump for a restart! Therefore, the self-priming pump check valve is best installed in the inlet pipe of the suction port.

- Q: Where can I get a solar powered water pump for a sprinker? I want the pump to pull water out of a river next to my yard and water my garden and lawn.

- Build okorder /

- Q: first off i should say it is below freezing here....with that said, the water pump pulley is not turnning so.. the fan belt busted which leads me to believe the water pump is frozen...... right?i am currently traveling and have little money to spend on a new water pumpis there any way that anyone may know to dethaw a frozen water pump without damaging it?... i should say, the motor is running great, no cracks or leaks from the cold.

- If the pump is above ground, yes it can freeze. It's more likely that the water line above the pump and well is frozen. Most well houses have heat tape around these lines. Make sure that is plugged in and working.

- Q: I have 2000 ford ranger v6 3.0 I replaced the water pump ten months ago and all of a sudden it's running hot it only runs hot when I stop for a second at a red light or stop sign. I changed the radiator today but still is running hot. The top radiato hose going to the thermostat housing is building a lot of pressure and the water is bubbling in the reservoir what could be wrong? And I took the thermostat out last week

- You're looking for an answer that may be hard to find. Have to assume the water pump and radiator are good. But there's a lot more to the cooling system. You could have one or more issues. For one, we don't know how well the water pump is spinning or if you changed the pulley so it's spinning slower. You have coolant channels in the block that go through the head gasket into the head. In a 12-year-old car, these channels could be partially blocked with crud and sludge. Stop buying parts and take your car to a good radiator shop. Possibly all you need is a good chemical flush to get rid of the sludge. For starters, turn on the heater which might keep the temperature in the operating range, but get some help from a radiator shop. ... Good luck!!

- Q: How does a pump pump water?

- Centrifugal pump is the use of centrifugal force to increase the pressure of water and make it flow of a pump. It is composed of pump shell, impeller, rotating shaft and so on. The motor drives the rotating shaft, the rotating shaft drives the impeller to rotate at a high speed in the pump casing, and the water in the pump is forced to rotate with the impeller to generate centrifugal force. The centrifugal force forces the liquid from the impeller periphery to throw, the high speed, the high pressure water flows through the pump shell outside the pump, the impeller center forms the low pressure, thus draws in the new water flow, forms the unceasing water current transportation function.

Send your message to us

Horizontal Mixed Flow Pump HW

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords