Heavy duty irrigation Mixed Flow Water Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

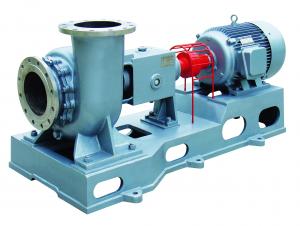

Heavy duty irrigation Mixed Flow Water Pumps

1) Features: A) Vertical structure

B) Fitted with vertical motor

C) Long shaft

D) High efficiency

E) Good vapor erosion resistance

2) Applications:

A) Hydraulic projects

B) Farm-land irrigation

C) Industrial water transportation

D) Water supply and drainage

E) Water allocation engineering

3) Technical data:

A) Flow: 83 - 48, 888m3/h

B) Head: 1 - 30.6m

C) Medium temperature: 50oC

D) Operation pressure: 2.5Mpa

E) Diameter: 350 - 1, 800mm

F) Power: 4 - 20, 00kW

G) Voltage: 355kW, 6kV, 10kV

4)Material Standard:

A)Casing: cast iron

B)Impeller:cast iron/ Carbon steel/stainless steel

C)Shaft: Carbon/Cr-steel

5)Pictures

- Q: When I turn on my pump for the pool water-fountain it will run for 30 seconds or 4 minutes or anywhere in between then it just shuts off. I push the remote on button on again and it runs for a few seconds. Sometimes it will run for a while longer but mostly short durations. Thanks in advance for your help.

- Contrary to another poster's reply, if it were an electrical problem and there was a larger than acceptable load (draw) on the electrical system, the breaker switch would click off as the amperage from the pump or wiring would create too great a draw. That is what breaker switches are for. It is likely that you have a vacuum leak or something plugging a line. Check the filter basket ... check the pool water return lines from the pool to the pump. Bleed air out of the filter. If those don't work, it would be time to call a pool service.

- Q: How do the water pump work please till me water pump mechanism?

- I assume you're asking about a car water pump. Inside of the pump casing is an impeller (a disc or wheel with vanes). The impeller is connected to a shaft that's connected to a pulley wheel driven by the drive belt from another pulley wheel mounted on the engine shaft. The pump, the radiator and the hoses make up a water filled, enclosed system. As the pump rotates when the engine is running, it circulates the water around the system removing heat from the engine and giving up the heat to the atmosphere through the radiator. ....

- Q: I just got a new boat with a diesel engine and I don't understand why there is a coolant tank as well as a water pump? I think the water pump goes to the heat exchanger but what actually cools the motor - how does this stuff work?

- Coolant can leak from plenty of areas. Without figuring out what style of motor you've got, can handiest bet. Hopefully it's not a cracked cylinder head. But if you'll see spraying out you have got to convey the automobile to a mechanic. Obviously you're going to run out of coolant quickly even though you preserve topping it off. And it is going to occur on the incorrect time and situation. The leak price will broaden because the motor heats up and expands.

- Q: we are trying to replace a water pump on our ford windstar mini van. my uncle cant figure it out and we can not get a manual until tomorrow. was wondering if anyone knew how. thanks

- 96 Ford Windstar

- Q: My 2000 Chevy Cavalier (2.4L) has been overheating pretty majorly (within a 10 minute drive!) when it's been super cold out, about 5F. I took it to the shop and they told me it was my water pump. Right after getting out of the shop, the problem went away for an entire week and the car's temperature has been at exactly what it's been for years - never past 195. It seems to be back now, though not as severe. It's about 20F now.Could the weather have to do with this??Why would the problem go away like that?I'm female and definitely do not seem educated walking into a shop so they can really tell me anything and I'll buy it. I just wanna see if the problem going away like that makes any sense, or if I should just wait out long trips until it warms up outside.It doesn't look like I'm losing coolant, though my low coolant light goes in and out.I have no idea. Thoughts?Thank you!!

- When the water pump goes you usually see obvious signs of leakage and a grinding metallic sound coming from it as well. Plus they usually go pretty fast, within a day or 2 of symptoms presenting, and then coolant is often gushing out. The thermostat is the more likely culprit. The thermostats on the '00-'02 Cavs are pretty bad. I've replaced (2) of them in 6 years on my car. Take it to another shop and let them look at it, point out that you think it might be the thermostat or water pump but you're not sure, at least you will sound like you have a clue what the problem might be.

- Q: i was coming home from from work and my jeep thew the serpenteen belt and my water pump is the only pulley not moving good like the rest and is leaking coolent. and people with just dump **** to say dont comment on this

- 1st off juan needs to get a life. now to help you .buy a haynes manual so you can go and do the removal and replacement of your water pump. step 1) remove the fan shroud 2) drain the coolant. make sure you do this so your critters won't drink it 3) remove the radiator. 4) remove the fan but do not remove the belt. this helps keep the fan from moving while you remove the bolts. if you have an electric fan remove this at the same time you remove the radiator 5) referring to the haynes manual remove any accessories that might be attached to the water pump 6) remove the pump. please refer to the haynes manual to insure you do the removal and re-instal correctly. oh yea, don't get fustrated . if you do just take a break. good luck and happy jeepin

- Q: I posted this earlier but nobody really answered my question . if my water pump is clearly on the serpentine belt I t need to replace the timing chain to get to it correct? The bolts holding the pump in are around it near the timing chain cover but they don't look like they are inside it. the pump is clearly driven by the serpentine so should I be fine not removing my timing belt to fix the pump? its leaking. Also I know you should replace the timing chain+tensioner but I inspected the chain 400 miles ago its properly tensioned the belt is in good condition its a chain it will last the life of the car its not the cheap belts.

- If you can change the pump without removing the timing belt then go for it, you are lucky. I don't replace the tensioner unless it needs to be replaced, usually they last a long time. I replace the timing belts every 60,000 miles, but usually you can go to 80,000 maximum but I don't like to take it to the last minute, not safe.

- Q: Which is the better option for a home water pump? a submersible pump or floor based pump?

- In case of pump failure, it's much easier to repair/replace a floor based pump plumbed with isolation valves and unions. I've replaced a few due to motor failures and flood damage. Arguably, the submersible pump wouldn't have suffered damage due to flooding. Another consideration is vertical pump height. A floor based pump has to draw a vacuum to induce water to flow up to the impeller. This limits the practical draw to between 25 and 30 ft. Much more than that height and the vacuum will exceed the vapor pressure of the the water, boiling it rather than pumping it. A special device can be used to boost the lift: an ejector is placed down the well. Water is pumped down to the ejector, which pulls additional water back up using the venturi effect. This method suffers from additional friction losses but has clear advantages. If you need to pump water up a well more than 20 feet vertical, you should consider a submersible pump, particularly if you are concerned about the possibility of the water table lowering.

- Q: I will be replacing my timing belt soon. The dealer is suggesting that I also replace the water pump. Is that really necessary? When do water pumps normally go out?

- Look at it this way. It is not just the dealer making this recommendation, it's every good mechanic out there plus Gates belt company who has no stake in it, they recommend replacing water pump and the car manufacturer says the same. No one is trying to rip you off but they are trying to save you money. In answer to your question about when do water pumps normally go out, the answer is right after you change just the timing belt and everything is buttoned back up. Trust me, it happened to a friend who tried to save money.

- Q: Is it accurate to say that it should begin at 2, not at 0?

- It freezes at 0 degrees, and the pump runs and gets stuck.

Send your message to us

Heavy duty irrigation Mixed Flow Water Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords