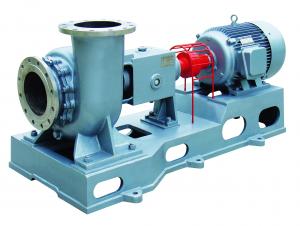

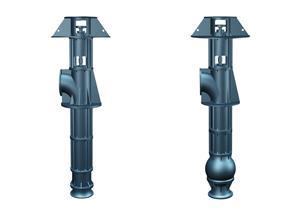

Mixed Gas Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Mixed gas water pump is suit for clear water,handling foamy,vloatile liquids,and mixture of liquid,vapor and air.

This kind of pump owns some advantages such as;compact small shape,light weight,simple structure,low noise,convernient for fixing.The axis seals are sealed by machinery.Thus,its sealed effect is very good.Motor Power 1.5~4KW, flow 4.5~17(m3/h), head3~48m。

- Q: Can an air pump be used for inflating air mattresses with memory foam tops?

- Yes, an air pump can be used to inflate air mattresses with memory foam tops. However, it is important to note that memory foam mattresses typically require less air pressure compared to regular air mattresses. Therefore, it is advisable to use a pump with adjustable pressure settings to avoid over-inflation and potential damage to the memory foam.

- Q: Can an air pump be used for inflatable beach balls?

- Yes, an air pump can be used to inflate beach balls.

- Q: Can an air pump be used for filling up oxygen tanks?

- No, an air pump cannot be used for filling up oxygen tanks. Oxygen tanks require pure oxygen, which can only be obtained through specialized oxygen concentrators or medical-grade oxygen cylinders.

- Q: Does the high pressure air function replace the air pump?

- 1, this depends on the specific pressure, equal pressure can.2, there is a overlap of pressure between the high pressure fan and the low-pressure air pump, not all the pressure of the air pump is higher than that of the fan.3, fans generally have more atmospheric flow, air pump flow is relatively small, this should consider the cost factor.

- Q: Are there air pumps with automatic shut-off features?

- Yes, there are air pumps available in the market with automatic shut-off features. These pumps are designed to automatically stop inflating once a desired pressure level is reached, preventing over-inflation or damage to the item being inflated.

- Q: Can an air pump be used for fish tanks?

- Yes, an air pump can be used for fish tanks. Air pumps are commonly used in fish tanks to provide aeration and circulation of water. They help to oxygenate the water, which is essential for the well-being and survival of fish. Additionally, air pumps can also power various types of aquarium equipment, such as air stones, sponge filters, and certain types of decorations.

- Q: How does an air pump handle continuous pressure adjustments?

- Various mechanisms are employed by an air pump to regulate and maintain the desired pressure level. One commonly used method involves the utilization of a pressure sensor or gauge to monitor the current pressure within the system. This sensor provides feedback to the pump, enabling it to adjust its operations accordingly. In order to increase pressure, the pump can boost its speed or activate additional components to compress more air into the system. This may entail adjusting the power output of the motor, opening valves to allow for greater air intake, or engaging a compressor to compress the air at a higher rate. Conversely, if a decrease in pressure is required, the pump can reduce its speed or deactivate specific components to lessen air compression. This could involve reducing the motor's power output, closing valves to restrict air intake, or disengaging the compressor to diminish the rate of air compression. The pump continually monitors the pressure and promptly makes adjustments to ensure that the desired pressure level is maintained. This capability enables the air pump to effectively handle continuous pressure adjustments and ensure the system operates within the necessary parameters. It is important to note that the specific mechanisms and control systems employed by an air pump can vary depending on the type and purpose of the pump. For instance, a smaller portable air pump may employ simpler mechanisms, while a larger industrial air pump may incorporate more advanced control systems to efficiently handle continuous pressure adjustments.

- Q: Are air pumps suitable for continuous operation?

- Indeed, air pumps are well-suited for continuous operation. Specifically engineered to deliver a consistent stream of compressed air, these devices are constructed to endure uninterrupted usage without overheating or encountering any glitches. They find widespread application in diverse areas, including fish tank aeration systems, hydroponics, pond aeration, and even industrial processes. The robustness and dependability of air pumps render them an optimal selection for ongoing operation, ensuring an uninterrupted supply of compressed air whenever necessary.

- Q: Can an air pump be used for vacuum packaging?

- No, an air pump cannot be used for vacuum packaging as it is designed to pump air into a specific area, whereas vacuum packaging requires the removal of air from the packaging to create a vacuum seal.

- Q: Can an air pump be used for inflating inflatable water toys?

- Yes, an air pump can be used for inflating inflatable water toys.

Send your message to us

Mixed Gas Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords