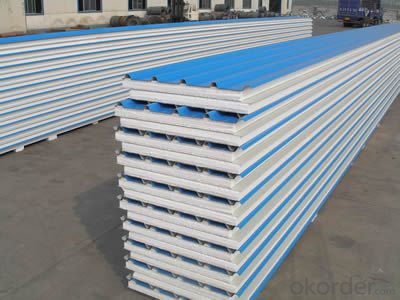

Galvanized Color metal glass wool sandwich panel for roofing and wall and warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1) light weight.roof tile2) high strength

3) waterproof and fireproof

4) fast and convenient construction

The galvanized color steel sandwich panels are polystyrene sandwich panels, which is very good at heat insulation.

1. The width of the sandwich panel is 930mm, and 1,150mm

2. Upper and lower layer: uses color steel plate

3. Thickness of the color steel plate: 0.3 to 0.6mm

4. Middle: polystyrene foam board

5. Thickness: 50mm, 75mm, and 100mm, 200mm, 300mm, etc.

6. Length: according to customer's request

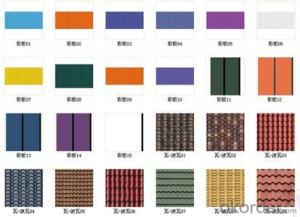

7. Color: white, green, blue, red, etc.

8. The products has good at warm keeping, and it is in low price

Base metal: PPGI,prepainted steel panel

Content of composite panels: Foam or Rock wool

Appliance: Wall panel and roof panel

Type of wall panel: one-side iron with foam;bottom with silver paper foam composite steel panel;bottom with film foam composite steel panel;jack type composite steel composite panel etc.

Type of roof panel: PVC and both sides iron panel;rock wool roof panel has buckle-style panle.

Thickness of foam: 5,7.5,10 cm

Weight of foam: 7,8,12 kgs

Thickness of rock wool: 5,7.5,10 cm

Weight of rock wool: 7,8,12 kgs

The colors,patterns,thickness of steel panel,measures are all designed by customer's request.

Packing the pipes into the bundles by the steel strip (2)packing the welded steel structure parts by some fabric (3)packing the small parts by bags and EPS foam (4)packing sets parts by some box or stock

- Q: How do steel structures perform in terms of thermal comfort and indoor air quality?

- Steel structures can perform well in terms of thermal comfort and indoor air quality. Steel has a low thermal conductivity, meaning it can help regulate indoor temperatures and reduce the need for heating or cooling systems. Additionally, steel structures can be designed with effective insulation to further enhance thermal comfort. In terms of indoor air quality, steel does not off-gas harmful chemicals and is resistant to mold and pests, contributing to a healthier indoor environment.

- Q: What are the design considerations for steel canopies and outdoor seating areas?

- Some design considerations for steel canopies and outdoor seating areas include durability, weather resistance, aesthetics, structural stability, and functionality. The steel used should be able to withstand harsh weather conditions and be resistant to corrosion. The design should also take into account the desired aesthetic appeal, blending well with the surroundings. Structural stability is important to ensure the canopy can withstand wind loads and other external forces. Additionally, the seating area should be comfortable and functional, considering factors such as seating capacity, accessibility, and user comfort.

- Q: What are the different types of steel windows used in buildings?

- There are several types of steel windows commonly used in buildings, including hot-rolled steel windows, cold-rolled steel windows, and stainless steel windows. Hot-rolled steel windows are made by heating and rolling steel sheets, resulting in a sturdy and durable product. Cold-rolled steel windows undergo a similar process but with cold temperatures, making them more precise and suitable for architectural designs. Stainless steel windows, on the other hand, are resistant to corrosion and often used in areas with high moisture or salt exposure.

- Q: How are steel structures designed to withstand dynamic loading from moving vehicles?

- Steel structures are designed to withstand dynamic loading from moving vehicles through careful analysis and engineering. This involves considering factors such as the weight and speed of the vehicles, the impact forces generated, and the structural response to these forces. Various design techniques, such as using appropriate structural members and connections, employing dynamic analysis methods, and incorporating safety factors, are utilized to ensure that the steel structure can withstand and safely distribute the loads imposed by moving vehicles.

- Q: What are the different types of steel floor systems used in building structures?

- Building structures utilize various types of steel floor systems, each possessing unique characteristics and advantages. 1. Incorporating both steel beams and a concrete slab, the composite beam and slab system forms a composite floor system. The steel beams serve as primary structural support, while the concrete slab functions as the floor surface. This system offers exceptional strength and rigidity, rendering it suitable for large span applications like commercial buildings. 2. The open web steel joist system comprises lightweight steel joists constructed from steel bars or rods. These joists are positioned parallel to one another and bear the load of the floor and roof. Due to their versatility, ease of installation, and cost-effectiveness, open web steel joists find frequent use in industrial and commercial buildings. 3. The steel decking system, also known as metal decking, involves placing steel sheets atop steel or concrete beams. During construction, the steel sheets act as formwork and subsequently provide a sturdy foundation for the final floor surface. This system commonly finds application in high-rise buildings, offering outstanding fire resistance, durability, and rapid construction. 4. The flat slab system eliminates the need for beams by directly supporting flat slabs of reinforced concrete on steel columns or walls. Steel reinforcement is embedded within the slab to enhance its strength. This system proves suitable for structures with heavy loads and necessitates fewer columns, thereby enabling greater flexibility in architectural design. 5. Similar to the composite beam and slab system, the composite slab system combines steel beams with a concrete slab. However, in this system, the steel beams are embedded within the concrete slab, generating a monolithic structure. The composite slab system excels in load-carrying capacity and fire resistance, making it ideal for multi-story buildings. Architects and engineers meticulously evaluate factors such as span requirements, load capacity, construction speed, fire resistance, and architectural flexibility to select the optimal steel floor system for a particular building structure.

- Q: Name of steel structure awning

- With high strength aluminum alloy material, the joint of column and ceiling is strengthened with galvanized steel structure, so it is more secure and firm. The surface of aluminum alloy is treated by powder electrostatic spraying, and the oxidation resistance is more than 30 years.

- Q: How are steel structures inspected for quality and safety?

- Steel structures are inspected for quality and safety through a combination of visual inspections, non-destructive testing techniques, and adherence to industry standards and codes. Trained inspectors thoroughly examine the structural components, welds, connections, and coatings to ensure they meet the required specifications. Various non-destructive testing methods, such as ultrasonic testing and magnetic particle testing, are employed to detect any hidden defects or flaws that could compromise the integrity of the structure. Additionally, regular inspections are conducted throughout the construction process and during the service life of the structure to ensure ongoing safety and maintenance compliance.

- Q: How are steel structures used in the construction of research centers?

- Steel structures are commonly used in the construction of research centers due to their exceptional strength, durability, and versatility. They provide the framework for the entire building, supporting heavy scientific equipment, laboratories, and offices. Steel's high load-bearing capacity allows for large open spaces and flexible floor plans, accommodating the specific needs of research facilities. Additionally, steel structures can be easily modified or expanded, making them ideal for future renovations or additions as research requirements evolve.

- Q: What is the performance and function of steel structure engineering?

- Steel structure engineering is mainly made of steel, with large span, steel structure, workshop frame, steel structure workshop, light overall, saving foundation, little material, low cost and short construction period. Safe and reliable, beautiful appearance, stable structure and other advantages. Steel structure workshop is widely used in large span industrial buildings, warehouses, cold storage, high-rise buildings, office buildings, multi-storey parking lots and houses and other construction industry.

- Q: What are the different types of steel staircase systems used in building structures?

- There are several different types of steel staircase systems used in building structures, including straight-run stairs, spiral stairs, cantilevered stairs, and helical stairs. Each type offers unique design possibilities and functionality to suit various architectural needs and space constraints.

Send your message to us

Galvanized Color metal glass wool sandwich panel for roofing and wall and warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords