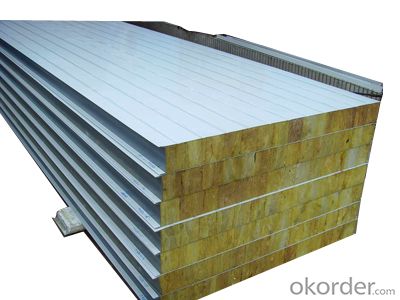

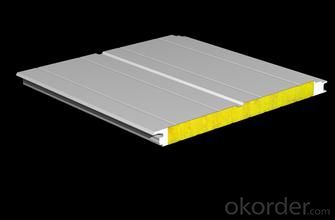

Fireproof Color Steel Glass Wool Sandwich Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Sandwich panel is a structure made of three layers: low density core inserted in between two relatively thin skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

Specifications:

Light weight

Excellent sound insulation and heat insulation

Easy installation

Fireproof and water proof

Long life:10-15years

Beautiful appearance

Size:

Item Data

Effective Width: 1150MM/960MM/950MM

Length: Can be customized

Materials: Glass Wool, Color steel sheet

Structure: Upper and lower layer: Color steel sheet

Middle: Glass Wool

Thickness of color steel sheet: 0.3-0.8MM

Colors: Blue, white or according to your requirements

- Q: How are steel sheets protected from damage during handling and transportation?

- Steel sheets are typically protected from damage during handling and transportation through various methods such as applying protective coatings, using packaging materials like plastic wrapping or wooden crates, utilizing foam or rubber padding, and using proper lifting and securing techniques to prevent any shifting or impact.

- Q: Can steel sheets be used in medical applications?

- Yes, steel sheets can be used in medical applications. They are commonly used in the manufacturing of medical instruments, surgical equipment, and medical furniture due to their strength, durability, and corrosion resistance properties.

- Q: What is the average cost of steel sheets per square foot?

- The average cost of steel sheets per square foot can vary depending on factors such as thickness, quality, and market conditions. It is recommended to contact suppliers or conduct research to get the most accurate and up-to-date pricing information.

- Q: How do steel sheets compare to other materials like aluminum or copper?

- Steel sheets have several advantages over other materials like aluminum or copper. Firstly, steel is much stronger and more durable than both aluminum and copper. This makes steel sheets ideal for applications that require high strength and resistance to wear and tear, such as construction, automotive manufacturing, and industrial machinery. Secondly, steel sheets have a higher melting point than both aluminum and copper. This means that steel can withstand higher temperatures without deforming or melting, making it suitable for applications that involve exposure to high heat or fire. Additionally, steel sheets are more cost-effective than both aluminum and copper. Steel is widely available and relatively inexpensive compared to these other materials. This makes steel sheets a more economical choice for large-scale applications that require a significant amount of material. Furthermore, steel sheets have excellent corrosion resistance properties when properly coated or treated. Aluminum and copper, on the other hand, are more prone to corrosion and require additional protective measures. This makes steel sheets a better choice for outdoor or marine applications where exposure to moisture and harsh environments is a concern. Lastly, steel sheets are highly recyclable, making them a more sustainable choice compared to aluminum and copper. Steel is one of the most recycled materials in the world, with a recycling rate of nearly 90%. This reduces the environmental impact and conserves natural resources. In summary, steel sheets offer superior strength, durability, heat resistance, cost-effectiveness, corrosion resistance, and recyclability compared to materials like aluminum or copper. These qualities make steel sheets a versatile and reliable choice for a wide range of applications across various industries.

- Q: What are the different types of coatings available for steel sheets?

- There are several different types of coatings available for steel sheets, including galvanized coatings, zinc coatings, aluminum coatings, and organic coatings.

- Q: What is the thermal conductivity of stainless steel sheets?

- The thermal conductivity of stainless steel sheets can vary depending on the specific alloy, grade, and thickness. However, on average, stainless steel has a thermal conductivity of around 16-26 W/m·K, which is relatively low compared to other metals like copper or aluminum.

- Q: Are steel sheets suitable for construction applications?

- Yes, steel sheets are highly suitable for construction applications. They offer exceptional strength, durability, and versatility, making them ideal for various construction projects such as buildings, bridges, and infrastructure. Steel sheets are known for their ability to withstand extreme weather conditions and provide structural stability. Additionally, they are cost-effective, easy to install, and can be recycled, making them an environmentally friendly choice for construction.

- Q: Which is good, z15 grade steel plate and z25 grade steel plate?

- Both Z15 and Z25 are the properties of steel against lamellar tearing. Their properties are marked by the fracture shrinkage index of tensile specimens in thickness direction (15 and 25 in Z15 and Z25 are the minimum values of fracture shrinkage)

- Q: How do steel sheets perform in vibration and noise reduction?

- Steel sheets are effective in vibration and noise reduction due to their dense and rigid nature, which helps dampen vibrations and minimize noise transmission.

- Q: Are steel sheets suitable for architectural roofing?

- Yes, steel sheets are suitable for architectural roofing. Steel sheets offer durability, strength, and longevity, making them a popular choice for architectural roofing applications. They can withstand harsh weather conditions, provide excellent protection against elements like rain, snow, and sunlight, and are available in a variety of designs and finishes to enhance the aesthetic appeal of a building. Additionally, steel sheets are lightweight, which reduces the overall load on the structure, and they are also fire-resistant, making them a reliable choice for architectural roofing.

Send your message to us

Fireproof Color Steel Glass Wool Sandwich Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords