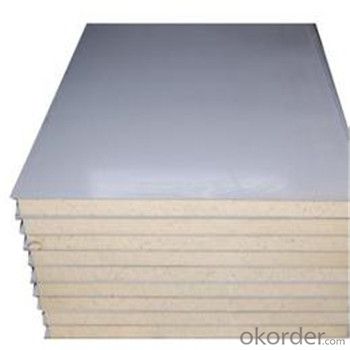

Polyurethane Sandwich Panels for Roof,Wall and Cold Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Waterproof and fireproof

2.Easy to install

3.Low thermal conductivity

4.ISO9001:2008, CE

5.Color coated steel surface

Advantages of SWE Polyurethane Sandwich Panels

1.Heat and sound insulation:The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2.A degree inflaming retarding:This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3.Environment protection:By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4.Super-low heat conductivity:The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

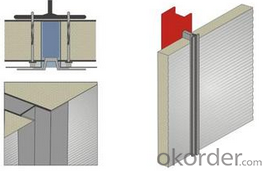

5.SWE polyurethane roof panel are tightly connected blind nailing

6.Easily and quick installation

The Special Features of SWE Roof Panels

Standard Width(mm) | 1000 |

Length(mm) | 3000≤L≤15000 |

Standard Overall Thickness(mm) | 50 |

Other Overall Thickness(mm) | 50 75 100 |

Outer Face(mm) | 0.5 or above as options |

Inner Face(mm) | 0.4 or above as options |

Core Material | PU |

Average Density of Core(kg/m3) | 40±2 |

Unit Weight of 50mm thickness(kg/m2) | 10.90 |

Thermal Conductivity of Core(w/m . k) | 0.022 |

FAQ

1. Could CNBM sent me some samples for free?

Sure, we can sent samples as your require, only need you to pay the Express fee.

2. Could we inspect the factory when we need?

Sure, welcome to CNBM to give us some suggestion at any time.

3. Does CNBM can guarantee the quality?

Sure, is there is any problem during the contract time, CNBM could supply all the support.

4. What can CNBM do for the costumers?

CNBM could supply the costumers from design, manufacturem shipping and installation, and also after-sell service.

- Q: How are steel structures used in the construction of airports?

- Steel structures are extensively used in the construction of airports due to their strength, durability, and versatility. They are used to create various components such as terminal buildings, hangars, control towers, and bridges. Steel allows for large open spaces and long spans, providing flexibility in design and accommodating the complex layout and requirements of an airport. Additionally, steel structures offer resistance to extreme weather conditions, seismic activity, and fire, ensuring the safety and longevity of airport buildings.

- Q: How are steel structures used in mining and mineral processing plants?

- Steel structures are widely used in mining and mineral processing plants due to their strength, durability, and versatility. They provide support for heavy machinery and equipment, including crushers, conveyors, and processing units. Steel structures also house storage areas for minerals and facilitate efficient transportation within the plant. Additionally, steel is resistant to corrosion and can withstand harsh environmental conditions, making it suitable for the demanding requirements of mining and mineral processing operations.

- Q: What is the role of steel in residential buildings?

- The role of steel in residential buildings is crucial as it provides structural support, ensuring the strength and stability of the building. Steel is commonly used in beams, columns, and foundations, allowing for open-floor plans and the ability to withstand various loads, such as the weight of the structure, occupants, and external forces like wind or earthquakes. Additionally, steel offers durability, fire resistance, and design flexibility, making it an ideal material in construction for creating safe and aesthetically pleasing residential spaces.

- Q: What are the different types of foundation systems used for steel structures?

- There are three main types of foundation systems used for steel structures: shallow foundations, deep foundations, and pile foundations. Shallow foundations, such as spread footings and mat foundations, are used when the soil can support the load of the structure at a relatively shallow depth. Deep foundations, such as drilled shafts or caissons, are used when the soil is unable to support the load at shallow depths and require reaching deeper, more stable soil layers. Pile foundations involve driving or drilling long, slender columns (piles) into the ground to transfer the load to deeper soil layers or rock. The selection of the foundation system depends on factors like soil conditions, site constraints, and the magnitude of the structure's load.

- Q: How do steel structures perform in terms of fire safety and fire resistance ratings?

- Steel structures are known for their excellent fire resistance ratings and fire safety performance. Steel has a high melting point, which allows it to retain its structural integrity for a longer duration during a fire. Additionally, steel does not contribute to the fuel load of a fire, reducing the risk of fire spreading. Steel structures are also equipped with fire protection systems, such as fireproof coatings, fire-resistant insulation, and sprinkler systems, further enhancing their fire safety. Overall, steel structures are considered to have high fire resistance and are a reliable choice for ensuring the safety of occupants during a fire.

- Q: Can steel structures be designed to be resistant to chemical attacks?

- Yes, steel structures can be designed to be resistant to chemical attacks. By selecting appropriate materials and employing corrosion-resistant coatings or alloys, steel structures can withstand exposure to various chemicals and prevent degradation or structural damage. Additionally, proper maintenance and regular inspections are crucial to ensure continued protection against chemical attacks.

- Q: How do steel structures perform in high winds?

- High winds are generally handled well by steel structures. Steel possesses high strength and rigidity, making it an ideal material for enduring strong winds and extreme weather. The inherent properties of steel, such as its high tensile strength and ductility, enable it to effectively resist the forces exerted by wind loads. To evenly distribute wind loads throughout the structure, steel structures are designed with inherent stability. This is achieved through appropriate bracing and cross-sectional shapes that effectively dissipate wind forces. Optimal performance is ensured by considering factors like wind direction, wind speed, and the specific location of the structure during the design process. Flexibility is often incorporated into steel buildings, allowing them to absorb and dissipate the energy generated by high winds. The ability to flex and deform under wind loads minimizes the risk of structural damage or failure. Additionally, the low weight-to-strength ratio of steel structures reduces wind pressure. Furthermore, steel structures can be further improved for high wind performance by incorporating additional features like aerodynamic shapes, wind deflectors, and streamlined designs. These measures reduce wind turbulence and prevent the formation of vortices, which can increase the wind forces acting on the structure. In conclusion, steel structures have a proven track record of performing well in high winds. Their stability, strength, and flexibility make them a reliable choice for areas prone to strong winds or extreme weather conditions. However, it is crucial to ensure that professionals design and construct the steel structure following the necessary codes and standards to guarantee its safety and performance in high winds.

- Q: What are the factors to consider when designing steel structures for sports facilities?

- When designing steel structures for sports facilities, several factors need to be considered. Firstly, the specific requirements of the sports facility must be taken into account. This includes considering the type of sports being played, the anticipated loadings, and any specific equipment or features that need to be incorporated into the design. Secondly, the location and environmental conditions of the sports facility are crucial. Factors such as wind loads, seismic activity, and climate conditions need to be assessed to ensure the steel structure can withstand these forces and provide a safe environment for users. Additionally, the size and layout of the sports facility should be considered. This involves analyzing the span and height requirements, as well as any potential expansion or modifications that may be needed in the future. Furthermore, the aesthetic aspect of the design should not be overlooked. Creating an aesthetically pleasing structure that fits within the surrounding landscape or urban environment can enhance the overall appeal of the sports facility. Lastly, it is important to consider the budget and project timeline. Designing steel structures for sports facilities requires careful cost estimation and scheduling to ensure the project remains within budget and is completed on time.

- Q: How are steel structures designed and constructed to meet sustainability goals?

- Steel structures can be designed and constructed in a way that aligns with sustainability goals by considering various factors throughout the process. To begin with, the design phase is crucial for ensuring sustainability. Designers can use advanced computer software and modeling techniques to optimize the structure's performance, minimizing material usage and waste. By employing efficient structural systems, such as utilizing steel's high strength-to-weight ratio, designers can reduce the amount of steel required while still maintaining structural integrity. In addition, steel is a highly recyclable material, and incorporating recycled steel into the construction process can significantly reduce the environmental impact. By using recycled steel, the carbon footprint associated with the production of new steel is minimized, and valuable resources are conserved. During construction, sustainability goals can be met by implementing efficient construction practices. For instance, prefabrication techniques can be employed, minimizing on-site waste and reducing the amount of time and energy required for construction. Moreover, construction processes should prioritize energy efficiency, such as using energy-saving equipment and opting for sustainable construction materials. To enhance sustainability further, steel structures can be designed to accommodate renewable energy systems. Features like solar panels, wind turbines, or green roofs can be integrated into the structure, reducing reliance on non-renewable energy sources and decreasing the building's carbon footprint over its lifespan. Lastly, steel structures can be designed with a focus on longevity and adaptability. By creating flexible designs that can accommodate future changes or expansions, the need for demolition and reconstruction can be minimized. This approach reduces waste generation and extends the lifespan of the structure, enhancing its overall sustainability. In conclusion, the design and construction of steel structures can be tailored to meet sustainability goals through efficient design practices, the use of recycled materials, implementation of energy-efficient construction methods, integration of renewable energy systems, and designing for longevity and adaptability. By considering these aspects, steel structures can significantly contribute to a more sustainable built environment.

- Q: How are steel structures used in wastewater treatment plants?

- Steel structures are commonly used in wastewater treatment plants for their durability, strength, and corrosion resistance. They are used to construct various components such as tanks, pipelines, and supports for equipment. The steel structures provide stability and longevity, ensuring efficient and reliable operations in wastewater treatment processes.

Send your message to us

Polyurethane Sandwich Panels for Roof,Wall and Cold Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords