End Suction Centrifugal Water Pump for Water Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

End Suction Centrifugal Pump

1.Structure of End Suction Centrifugal Pump Description

End Suction Centrifugal Pump complies fully to the European Standard BS EN733 / DIN24255 of performance and dimensions. They are used for pumping clean water or liquids similar to water, achieving wide application on plants, mines, city water supplies, air-conditioning coolers, firefighting system and irrigation. Pumps of the same model have different performance levels basing on different diameter after impeller trimming. Overall the whole series, there are only four sizes of shaft and five of bearing housing. As long as their bearing housings are of the same size, different pumps can interchange chief parts such as shaft, shaft sleeve, shaft seal, impeller nut, etc.

End Suction Centrifugal Pump is also very easy to be installed and maintained. Back pull-out design, driven through flexible coupling, so that pump casing and motor can remain in position while other spare parts are removed.

2.Main Features of the End Suction Water Pump

• very easy to be installed and maintained

•Back pull-out design

•Driven through flexible coupling

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

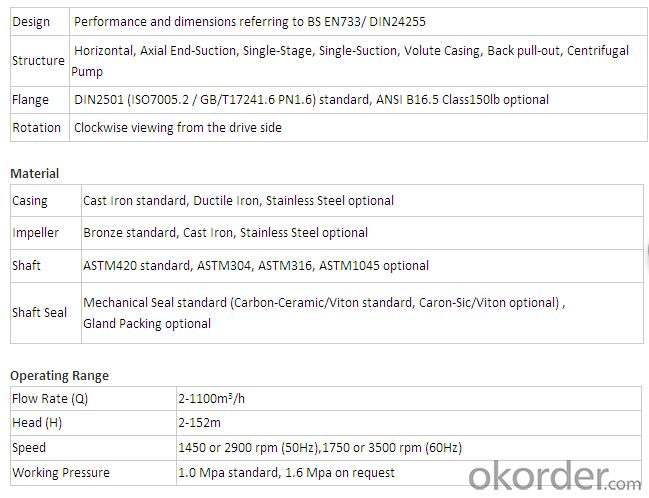

3.End Suction Water Pump Specification

4.Picture of End Suction Pump

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: A pump parameter is the maximum flow per hour 960L, followed by the standard flow of 480 what do you mean?

- Centrifugal pump, flow and head is an inverse relationship between the maximum flow, you said, lift the corresponding conveying pump is relatively low, the standard flow, the rated flow is designed and run in standard flow, pump efficiency is the highest, if more than the standard flow operation possible lead pump overcurrent heating, and a series of cavitation phenomena

- Q: My mechanic doesn't get back in town until next week, and I'm struggling without my car. I don't really have any other options mechanic wise and I'm not dropping $1000 like meineke wants.How easy is it to follow the Haynes repair manuals or any other repair manuals? I have a 1996 dodge avenger and I need to replace my water pump. I know it's a time consuming task, but is it especially hard to replace it?

- If you don't have any experience working on cars aside from changing oil my suggestion is to take it in and get it done. You need to drain the coolant, loosen the belt, and then try and torque off those bolts that are prolly sticky on the water pump. And if the water has eaten through the gasket you may need to get the engine block redone where the water pump rests. Oh but don't go to Meineke yuck, you might as well pull your pants down at your own house and sit on a plunger handle; at least it is free and will probably be less painful.

- Q: I need to do a new water level indicator interface for an experimental rig. I'm going to have the buttons that will start and stop the pump. And a column that will show the percentage of the water level in the experimental rig. Please help. I'm so clueless. And this is my final project. :(

- They're equal (VB and VB6 variations of VB, surely VBA is super high-degree) in the phrases of where they rank within the excessive-stage/low-stage programming language rankings. Java is extra priceless without problems for the reason that it results in other matters (and could be very marketable on it's own), particularly c/c++/c# and net languages like php/javascript which have c-like cyntax. VB.Web and VB6 don't particularly result in so much (although they each support comprehend object-orientation). you can do the identical matters with visual normal that you can do with Java or C++. You are not able to do the identical things in VB as c++. For C# that you would be able to make a small case because it does aid c++-like code (hazardous keyword) but absolutely not VB.Internet (or VB6 most likely). Just are trying doing a C# an identical of stackalloc in VB.

- Q: The plumber has disappeared on us with 99% of the job done. Our new basement remodel has baseboard heating installed, a water pump attached to the furnace/boiler, but no heat downstairs because their is no thermostat. I haven't checked to see if he did any wiring. (Wouldn't that be an electrician's job?) I've ordered a wireless thermostat kit, and I'm assuming installation instructions for the base are included, but it hasn't arrived yet. What should I do to get that pump pumping hot water to keep us nice and cozy?

- That part in the picture is a high limit control with manual reset. It has nothing to do with the pump. You will need more than a thermostat to control the added pump. When you have more than one pump the system is zoned .You need a switching relay panel (Taco SR502) that not only turns on the pump , but also the burner. There is a lot to know here and it's best left to a heating contractor.

- Q: i mean, the water that runs through the ground from rain and ends up in the pit in the basement,is it clean to drink in an emergency? live close to a public road where they salt for snow and ice, so do you suppose that is in the water?

- Probably NOT safe. Any run-off residue or water coming through the ground will contain many chemicals and compounds you can't ingest.

- Q: i have a 2003 dodge neon and my thermostat keeps rising to the highes level setting off the indicator (its not broken) i did have a leak in the raiditor and it was very notice able..after pacthing is up there was noproblem till yesterday now the thermostat keeps rising i admit the is very little antifreeze in ther and the rest is water but the is the same mixture tha was in the care that it was rinning off for the last three minths i cannot seem to keep the thermostat down my raiditor is in nee of repair but i m wondering if its the water pump does the water pum help regulate engine temperture? ther are no ivsible leaks and no drippiage could it be that i just need to put antifreeze or could it be the water pump or a broken raidiator? help i will give points for best anwser but really i just need help!

- All water pumps have what is called a weep hole and when the water pump seal goes out antifreeze will come out of the weep hole and stain the surrounding area. If your radiator was leaking its probably best to replace it and never use any of those stop leak products. They are more of an emergency repair to get you home until you can get the leak fixed properly. Have you changed the thermostat. When you put in antifreeze do you mix it with tap water or distilled. Distilled is always the best as tap water will leave mineral deposits inside your cooling system. Also on the thermostat they make what is called a fail open thermostat that allows for coolant flow even if the thermostat fails where as a regular thermostat fails in the closed position and will cause overheating. Always run at least a 50/50 mixture of antifreeze and distilled water because it not only protects from freezing but raises the boiling temperature as well. Good luck.

- Q: How to design its control circuit, to prevent it idling, what peripheral equipment do you need?

- The empty transfer of the centrifugal pump causes dry grinding, and the pump is overheated and seals out.Frequency control cabinet can be used to set their own frequency required job requirements, the external need is contact, is the pressure gauge

- Q: Water pump 50HZ impeller and 60HZ what is different, why not the same?

- Water pump 50HZ impeller and 60HZ impeller, its outer diameter is not the same, 60HZ impeller slightly smaller. Because the speed of the impeller of 60HZ is faster, the impeller is a little smaller.Flow rate and speed, impeller diameter into a relationship: Q1/Q2 = n1/n2=D1/D2;Head and speed into two relations: H1/H2 = (n1/n2) 2Motor shaft power and speed into three relations: P1/P2 = (n1/n2) 3From the above deduction, we can know that the motor speed formula is n=60f/p, in which n is motor synchronous speed, and F is supply frequency. P is the pole number of the motor. It is known that the power supply frequency of the motor is proportional to the speed of the f. Therefore, to obtain the same head or flow, high speed, to use a smaller impeller.

- Q: is there a water pump capable to pump up to 1/4 of an inchsand from 90' deep well?

- If the sand is suspended in the water then yes there are pumps that will pump it. Other wise no.

- Q: Pump performance parameters have three sets of data, how to understand the flow, lift, flow speed

- 1, the head is composed of a water pump design decisions, such as motor speed, power, blade shape; the flow is determined by the motor power and lift, the same power lift higher flux is small; velocity determined by flow and pipe section with a pump pipeline section greater velocity.2, the pump is to transport liquid or liquid pressurization machinery. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids. Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

Send your message to us

End Suction Centrifugal Water Pump for Water Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords