Easy Operation and Safety Tunnel Formwork

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

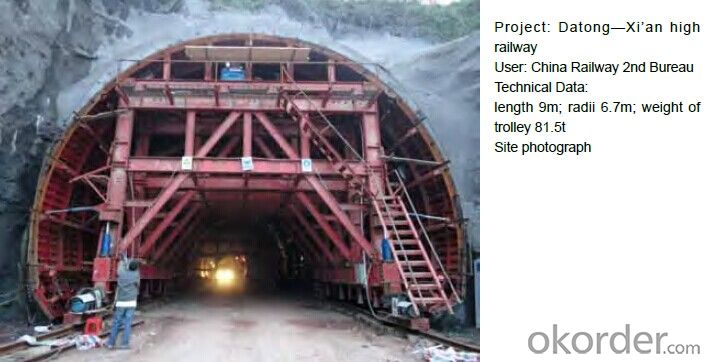

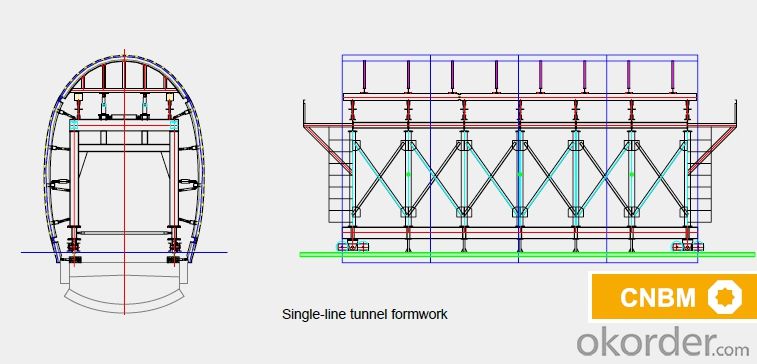

TUNNEL FORMWORK

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

◆ Good concreting quality

◆ High-speed of installation and removal of the form

◆ Easy operation and safety

- Q: 1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- Hope to help you. If the human eye to adapt to different levels of illumination, the need to go through three processes, namely, changes in the size of the pupil, nervous system adaptation, cone and rod cells of the photochemical adaptation of pigment.

- Q: Ask, general highway tunnel measurement with the total station to measure which aspects? The more detailed the better

- Slag road slope line, shotcrete receiver measurement, measurement of highway tunnel excavation section, the most important measure is the monitoring and measurement precision of total station but couldn't finish that much. Ha-ha

- Q: Highway bridge template needs, probably with the thickness of both the construction requirements can be met, and more cost-effective?

- According to the actual situation of your project

- Q: For example, lining, invert, bias and so on words,, to answer the full thank you

- Inverted arch: the general shape of the tunnel are horseshoe. Then the bow that you look up at is called an arch or vault

- Q: The tunnel lining is wood, how should support?

- Two concrete tunnel lining, template is used according to the size and shape of the tunnel design custom-made, I-beam welded frame, welded steel plate, known as the "two trolley liner" (hydraulic jack lifting and installation of steel wheel moving on the rail), is generally the length of 9~12m, concrete pouring pump concrete.

- Q: Would you please tell me the difference between the concrete and shotcrete in the tunnel?

- Characteristics of shotcrete:(1) the sprayed concrete has the characteristics of rapid growth, strong bonding force, high density and good impermeability. It can better fill the gap between the rock blocks, increase the integrity of the surrounding rock, prevent the free surface weathering and loosening, and work together with the surrounding rock.(2) the construction of shotcrete will transfer, pouring and tamping a few processes into one, and do not need a template, so the construction of fast, simple.(3) sprayed concrete can play an important role as early as possible.(4) compared with the concrete, the physical and mechanical properties of sprayed concrete are improved.

- Q: How to design the general layout of the tunnel construction organization design

- A very simple plane diagram, indicating the location of the tunnel, into the construction of the sidewalk and the construction of sidewalks, mixing stations and storage yard, air compressor unit location

- Q: Demolition of tunnel bearing formwork for several days

- With the temperature, the need for concrete strength of 100% to remove the template

- Q: In the tunnel construction, the water stop belt and the water stop strip are respectively used in what place, the construction joint and the subsidence seam many meters set a, above all has any function

- 5, the user should be based on the order of the project structure, design drawings to calculate the length of the product, the special-shaped structure should have drawings, as far as possible in the factory will be connected to the whole

- Q: There are no recycling tunnel templates

- If it is a tunnel two lining car template, and the use of the tunnel after the car can continue to use the value of such a tunnel lining car basically has a market of two, but also to be recycled. The specific recovery and continue to use, mainly to see the two lining of the tunnel and the old and new without modification.

Send your message to us

Easy Operation and Safety Tunnel Formwork

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords