Bridge formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

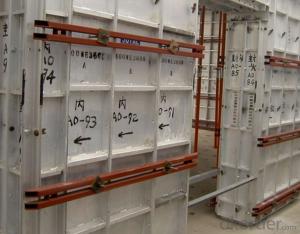

Building Bridge Formwork:

A compositional steel formwork system mainly used in the building which has regular structure

without beams, the excellent formwork system can make the integral pouring for the wall & slab

easily achieved.

Characteristics:

◆ No assembling, easy operation with formed formwork.

◆ High stiffness, make perfect shape for concrete.

◆ Repeatedly turnover is available.

◆ Widely applied range, such as building, bridge, tunnel, etc.

- Q: Where is the B-B section of the tunnel invert reinforcement

- Tunnel arch wall refers to both sides of the tunnel wall and the top of the arch, the tunnel arch wall is generally the use of a template trolley.

- Q: 1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- The pupil is 5 times as fast as the increases, which makes the dark adaptation time to defend much longer. Cone cells can produce or reduce pigment in 10 ~ 12min, and the rod cells are almost 60min need to produce all of the pigment, which makes it very difficult for people to adapt to a very dark environment. How long does it take, depending on the extent of illumination.

- Q: The tunnel structure of plastic mould

- The tunnel model is a kind of tool form template which is used for pouring concrete wall and floor at the same time.Total tunnel mode tunnel mode and half tunnel mode two, the basic unit of the tunnel mode is a complete tunnel template, half tunnel is composed of a plurality of unit angle die, and then use the 2.5 tunnel mode to fight and become a complete tunnel mode.

- Q: What is the role of the grid steel frame and steel mesh in the power tunnel

- The back cover, shaft ingate construction, to get rid of the upper advanced small pipe grouting reinforced concrete, erecting of ingate upper grille steel frame, injection, get rid of the upper concrete lower reinforced concrete, erecting of ingate to spray the concrete lower grille steel frame.

- Q: Tunnel steel arch behind the steel mesh after a layer of fine iron wire mesh what effect is there?

- 3, advance small catheter grouting small catheter with diameter of phi 32-50mm steel pipe, the tip of the tube and tube holes for special processing. The first row with drill drilling pipe. Row spacing is 30cm, fan shape, elevation of 5 degrees to about 8 degrees. The length is 2.25m, a single fluid grouting (cement) or double grout (cement water glass slurry). Adjust the grouting pressure according to the soil.

- Q: I would like to know the safety awareness of the tunnel lining formwork trolley Prawns to help answer oh

- Two during the 1 excavation of earthwork calculating boundary line is important??? 2 measuring points as far as the standard

- Q: What is the simple calculation method of the tunnel excavation unit price

- Fully integrated unit price = labor + material equipment + + + + + + + management fees

- Q: Main diseases and prevention of tunnel

- Main diseases and prevention of tunnel1 over excavation in tunnel excavationPhenomenon: in tunnel excavation, the upper, lower, left and right contours are exceeded.The reason analysis: the measurement is not allowed, the deviation is big; the hole position deviation is bigger; the hole in the hole drilling process does not have the straight hole to have the slanting hole to exceed the limit; the blasting parameter choice is wrong, the charge quantity is too much or unreasonable.Preventive measures: to ensure the measurement work turnover review system; accurate calculation of blasting parameters, the formal process test before entering the tunnel, timely adjust the parameters change of geological condition; hole position and direction control in drilling process.

- Q: What are the steps? If you build a template, how to fill in the concrete. The tunnel is to dig all the generalist pouring, or digging into the side. Simply say. Better picture. In addition, we have seen a video, the shield machine to dig up the tunnel after the installation of a number of prefabricated panels, but these prefabricated plate is curved. Do not have to fill in a semicircle tunnel?

- Tunnel concrete is completed by the way of edge excavation and lining. After the excavation, the shotcrete is used as the initial support, and then the reinforcing steel mesh is set up. Only after the two lining.

- Q: What is the first project of tunnel constructionNow to do some of the tunnel program, you need to be the first to list out, a total of what? I know that the first branch, two lining, inverted arch, tunnel, pavement these

- Summary of construction of the first two tunnel lining

Send your message to us

Bridge formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords