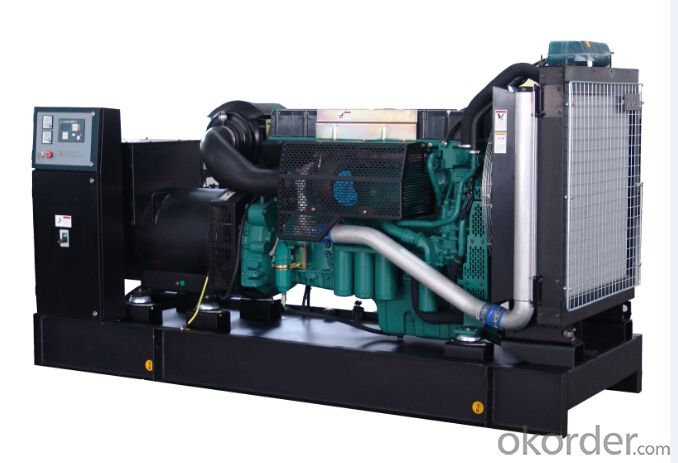

Diesel Generator Perkins 100kw/130kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

A diesel generator is the combination of a diesel engine with an electric generator (often an alternator) to generate electrical energy. This is a specific case of engine-generator. A diesel compression-ignition engine often is designed to run on fuel oil, but some types are adapted for other liquid fuels or natural gas.

Diesel generating sets are used in places without connection to a power grid, or as emergency power-supply if the grid fails, as well as for more complex applications such as peak-lopping, grid support and export to the power grid.

Main Product Features:

Engine (Perkins Model: 1106A-70TG1)

Radiator 40`C max, fans are driven by belt, with safety guard

24V charge alternator

Alternator: (Marathon Model: MP-104-4), single bearing alternator IP21, insulation class H/H

Absorber

Dry type air filter, fuel filter, oil filter

Main line circuit breaker

Standard control panel

Oil drain pump

One12V batteries, rack and cable

Ripple flex exhaust pipe, exhaust siphon, flange, muffler

User manual

Product Specifications:

1. Manufacturer / Model: Perkins Model: 1106A-70TG1,4 stroke

2. Air Intake System: Turbocharged, air-to-air charge cooling

3. Fuel System: /

4. Cylinder Arrangement: 6 in line

5. Displacement: 7.0L

6. Bore and Stroke: 105×127mm

7. Compression Ratio: 18.2:1

8. Rated RPM: 1500rpm

9. Max. Standby Power at Rated RPM: 132kwb

10. Governor Type: EMS2

FAQ:

Q1: What is Prime Power and Standby Power Rating?

A1: Prime Power (PRP): Prime power is available for an unlimited number of annual hours in variable load application, in accordance with GB/T2820-97(eqv ISO8528); A 10% overload capability is available for a period of 1 hour within a 12-hour period of operation. Standby Power Rating (ESP): The standby power rating is applicable for supplying emergency power for the duration of a utility power interruption. No overload, utility parallel or negotiated outage operation capability is available at this rating

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 30 to 40 workdays.

Q4: What is your after sales service?

A4: CNBM provides a full line of brand new and high quality products. Each and every unit is strictly factory tested. Warranty is according to our standard conditions: a, 15 months, counted on the day CNBM sold to the first buyer; b, One year after installation; c, 1000 running hours (accumulated); subject to the earlier one. Service and parts are available from CNBM or distributors in your location.

- Q: Generator prices? Diesel generator prices?

- Unit configuration (optional unit configuration on charging) is an important factor affecting the unit price, unit optional configuration: split the daily fuel tank, integrated base fuel tank, battery charger

- Q: I bought an old moving truck that I only want for storage. It will be parked on my off grid property. I would like to rig it to run a generator that could charge up a large bank of batteries for when my solar isn't collecting enough power. I know it can be done but I'm curious first, how to do it, and second, if it's worth doing? Thank you very much for your input.

- For emergency and the occasional deep cell charge up, yeah why not. You could either use the alternator that came with it, and maybe add a few more, or head down to Harbor freight and buy a 10kv generator ($350)and hook it up to the back side of that 7.2 using a few parts from behind the Grainger parts counter. However, if this is a 7.3 Ford(International) motor we're talking about. You're better off selling it for parts and buying a brand new Honda or Onan generator. Those international motors are a headache.

- Q: Hi -- looking for specifically Lister Petter Diesel Generator parts distributor in central Cal. Electrical parts -- cycle timers, a/c disconnects, etc.,. The main company (ListerPetter)is closed until after the 5th, and this machine powers my home, in the process of battery conversion project, and looking to finish this project between th holidays. THis is my hubbys endeavor -- I am just the messenger -- so I hope these questions make sense, please feel free to email me more details or anyhelp you think useful. Thanks everyone

- Depending on where you live try the on line yellow pages. Especially in large farming areas, like Fresno or Bakersfield, Stockton etc. Their will be equipment parts shops that will help you find what you need if they do not have it.

- Q: I have a 3 bedroom / 1 bath home. It is just 2 of us in the house. Also, I've heard that there is way to plug your generator into any wall outlet and it will charge your whole house. Any truth to this?

- It depends what you want to power. If you only want it for your fridge, gas stove, portable lamps, and to charge batteries, a 3 to 5 KW one will do. If you wanto power a few key circuits, likely a 5K to 7K generator with a manual transfer panel will do, with your essential circuits moved to it. For a whole home, you want a 10 to 15KW fixed generator with an automatic transfer panel. Plugging any power source into existing outlets is dangerous and illegal. If you want to tie a generator into your house wiring, you need an approved transfer switch or panel, and it installed by a qualified electrician.

- Q: I will put this generator to power my automated vehicle which have sensors, servo for the steering, motor for the rotation of the rear shaft, laptop for camera vision etc.

- A battery powered wheel chair has everything you need. You can buy an old one cheap and fix it up to work as your automated vehicle. Use Lithium Ion batteries for maximum power or one of the new AGM car batteries that provide deep discharge operation.

- Q: I want to know if i can get a 40kvh generator (witch is usually ran by 4 cylinder diesel engine) to run with a water wheel and some poulies??

- (Assuming kvh is a misprint for kVA) If you can (1) get a big enough water wheel (40kVA 40 000 Newton-metres per second: you would need about 4000 kg of water per second falling through a height of 1 metre to run it at full capacity, increasing the fall or reducing the maximum load will reduce the required flow rate) and (2) ensure that you can get the generator to spin at 3000 rpm (to get 50 cycles a second) then yes.

- Q: Effects on health, economy, business, the environment, etc.

- Deisel emissions are evil

- Q: I want to build a deisel generator that electrolizes water to make oxygen and hydrogen to increase fuel efficiency. Then I want to make an algae bioreactor and extract the fuel from the algae to power my diesel generator. What is the smallest engine that can support this? Do I need fuel injection or can the oxyhydrogen come in through the air intake? As I understand with oxyhydrogen added you can acquire a 100% fuel efficiency.

- I'll guess HOH can be used, with all sizes of diesel and gasoline motors, likely even in gas turbine motors and jet engines, BUT it as near zero utility for any of them. Even the fractional hp model airplane motors should work. More than a pint of HOH Brown's gas is a serious explosion hazard, so be sure production is reduced while the motor is idling.

- Q: I want to power a water heater, a blower fan, and a small water pump continuously with a diesel generator run on Biodiesel. Is it possible to set up a system of some deep cycle batteries that will carry the load for say 1/2 hour or 1 hour and have the generator kick on automatically when the voltage drops to charge the batteriesthis way the generator will not be run continuously. What would you need to set this up? Anything besides what I have mentioned?Josh

- Let's say you've worked out all of the basic power balances. How many times do you expect the batteries to be recharged in a year? Even really good batteries will only recharge a limited number of times (maybe 2000?). And they are expensive!

Send your message to us

Diesel Generator Perkins 100kw/130kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords