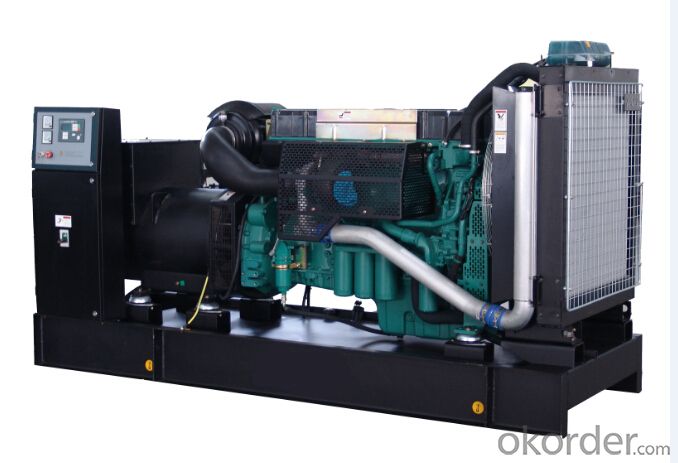

Diesel Generator Volvo 100kw/130kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

A diesel generator is the combination of a diesel engine with an electric generator (often an alternator) to generate electrical energy. This is a specific case of engine-generator. A diesel compression-ignition engine often is designed to run on fuel oil, but some types are adapted for other liquid fuels or natural gas.

Diesel generating sets are used in places without connection to a power grid, or as emergency power-supply if the grid fails, as well as for more complex applications such as peak-lopping, grid support and export to the power grid.

Main Product Features:

General Features: Engine(VOLVO TAD532GE)

Radiator 55`C max, fans are driven by belt, with safety guard

24V charge alternator

Alternator: single bearing alternator IP23, insulation class H/H

Absorber

Dry type air filter, double fuel filter, oil filter, coolant filter

Main line circuit breaker

Standard control panel

Oil drain pump

Two12V batteries, rack and cable

Ripple flex exhaust pipe, exhaust siphon, flange, muffler

User manual

Product Specifications:

1. Manufacturer / Model: VOLVO TAD532GE, 4-cycle

2. Air Intake System: Turbo

3. Fuel System: Directly Injection Fuel System, Bosch Pump

4. Cylinder Arrangement: 4 in line

5. Displacement: 4.76L

6. Bore and Stroke: 108*130(mm)

7. Compression Ratio: 18

8. Rated RPM: 1500rpm

9. Max. Standby Power at Rated RPM: 125KW/170HP (with fan)

10. Governor Type: EDC4

FAQ:

Q1: What is Prime Power and Standby Power Rating?

A1: Prime Power (PRP): Prime power is available for an unlimited number of annual hours in variable load application, in accordance with GB/T2820-97(eqv ISO8528); A 10% overload capability is available for a period of 1 hour within a 12-hour period of operation. Standby Power Rating (ESP): The standby power rating is applicable for supplying emergency power for the duration of a utility power interruption. No overload, utility parallel or negotiated outage operation capability is available at this rating

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 30 to 40 workdays.

Q4: What is your after sales service?

A4: CNBM provides a full line of brand new and high quality products. Each and every unit is strictly factory tested. Warranty is according to our standard conditions: a, 15 months, counted on the day CNBM sold to the first buyer; b, One year after installation; c, 1000 running hours (accumulated); subject to the earlier one. Service and parts are available from CNBM or distributors in your location.

- Q: (sorry for my English) i don't know anything about electricity generation but i ask this with a curiosity ok. a factory open 8.00 am to 4.00 pm and using 80kWh der day or 10000 w electricity in a given time it generate electricity by a diesel generator.is it possible to use a small diesel generator to generate enough power to run a motor and connect that motor to large power generator to generate whole electricity need for factory so we can save diesel and money possible or not

- No, it is not possible. All energy conversion devices are less than 100% efficient.

- Q: How many gallons of diesel would br required to run this generator for 24 hours??

- Consumption of fuel is actually dependent on the model used so it can vary, your best resource is to get the figures from a manufacturer, take for example the Generac II Emergency Power Systems provide a Diesel Model EPS-8D see link below for full specs: So if we based on this model which consumes 0.88 gallons per hour, running for 24 hours would eat up 21.12 gallons of diesel per generator. As to the amount of current you wish to get that would depend on other set up and implements that you hook to the generator. You may need more than 1 generator to get the total amperage that you are looking for. See the equipment specs.

- Q: i want to buy a generator for our company i want to know how to calculate current for 1000kva capacity generator. and also want to know control and protection are required for the same generator please explain.

- Depends what the voltage is. If it is a 1 Volt generator then it puts out 1000000 Amps. Use the energy equation to find out the current, - voltage relationship. PowerVolts * Amps. You may need to synchronise this with other electricity sources so there needs to be a system that does this and only connects them when they are in phase, and that disconnects it if the phases start to drift apart. Otherwise the generator will destroy itself.

- Q: i have an old marine onan generator. It is a two cylinder diesel engine and the block is almost round on the bottom. I thought it was a cummins but im not sure. I know it is vague but can anyone help.

- the other guys are right cummins owens onan. sounds like a 750 kw it is a good lighthouse, you find that it uses about .2 gl an hour of diesel. its some what hard on raw water impellers ( carry an Extra) and you'll need to change the mounts to stop some of the vibration other than that its been very reliable for me. it powers my 53 foot trawler no problems.

- Q: How to shut off the diesel generator

- diesel generator set off: the control switch to stop (STOP) position or press the red emergency stop button to stop the operation of the generator

- Q: As the generator is for emergency, so it stopped for long time and only run for preventive maintenance, so its not accomulate running time, what is the standard to evaluate the need for maintenance ?

- First make sure the fuel is fresh periodically. Old fuel deteriorates makes it hard it start and run. Second check the oil see if it is clean, check the oil filter too. Third check the fuel filter, change once a year if not used because of bad / old fuel. Forth Check the out put of the engine / voltage / oil pressure / amperage / operating temperature / current fuses / transfer switches are working properly. Listen and make sure the engine is running smooth, no misses. Should be good to go then.

- Q: if the answer is a regular car, how can hybrids possibly be more efficient than a regular car, since some of the power from the gas engine goes to the generator for the electric motor.

- Generator okorder

- Q: how exactly to fossil fuel power plants work?

- Fossil fuel power plants burn fossil fuels (coal, oil, natural gas) and heat water to produce steam which turns a turbine to drive a generator which produces electricity.

- Q: I want to purchase a solar powered backup generator in the event that we have a power outage. I don't want a gas/diesel generator as I don't want to have to fight everyone else to get gas for a generator. I've been only able to find one solar generator that would seem to work for my home. Any suggestions?

- Here okorder

- Q: 1 want know exactly defrences between heavy duty and continuous diesel generator sets? for examle for 1250 kva diesel generator, the defrences between their speeds and injection power of 2 kind of diesel generator. heavy and continuous duty.thanks

- 1 want know exactly defrences between heavy duty and continuous diesel generator sets? for examle for 1250 kva diesel generator, the defrences between their speeds and injection power of 2 kind of diesel generator. heavy and continuous dut

Send your message to us

Diesel Generator Volvo 100kw/130kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords