Cast Iron Listed Fire Pump High Quality Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

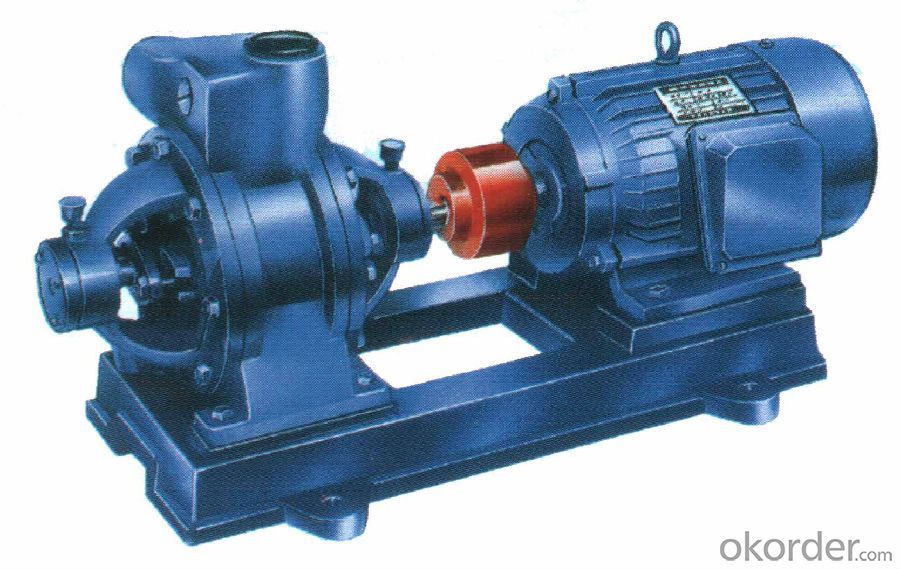

Cast Iron Listed Fire Pump High Quality Low Price

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product Parameters of Cast Iron Listed Fire Pump High Quality Low Price

| Capacity: | 20-200L/s |

| Head: | 0.3-1.28MPa |

| Speed: | 2900r/min、1450r/min |

| Power of fitted motor: | 0.75-250kW |

| Inler diameter: | 25-300mm(1"-12") |

Application Range of Cast Iron Listed Fire Pump High Quality Low Price

It is mainly used for the water supply for the fixed firefighting system of both industrial and civil building

fire hydrant fire-extinguishing system,

automatic spraying,

fire-extinguishing system.

Cast Iron Listed Fire Pump High Quality Low Price Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Picture Show

Why choose us

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q: What are some good brands of aquarium water pumps? I have had bad experiances with Hydor Seltz (cheapest ones I could find, ugg, I know, you get what you pay for) pumps, failing very quickly, and sounding like plastic gears grinding around inside. What is the best kind to get?I need one that's around 150gph

- PowerHead? or Sump Pump? I have used hagen aquaclear powerheads on my saltwater tanks for years 24/7 without a problem. I just purchased 3 MaxiJet 1200 powerheads and a wave timer to see haw they do, 6 months now 24/7 and so far so good. The longest lasting Sump Pump that I have ever owned is made by Ehime, I've had it for 14 years now and it's still going in one of my tanks. I better cross my fingers on that one.LOL

- Q: I think the water pump is going out in my truck can I still drive it short distance if I put water in it first?

- You might be able to drive short distances. but if you rev the engine it might go out. to be safe i would to it. if it still works and hasent went out on you yet than you might be able to drive it. Good Luck

- Q: How can we calculate the maximum pump pressure for chilled water system for a 20 story building

- 20 storey's, let's say 200 feet. 200 x 0.433 = 86.6 psi. at ground level and about 0psi at the top. The pump, in order to deliver water to the top would need a pressure in excess of 87 psi but, the volume of pumped water would need to be high enough to cope with a number of people using it at the same time as this will starve the upper storeys if insufficient. Generally, a tall building will have booster pump stations on other floors up the building to ensure adequate supply.

- Q: Water is pumped out of a holding tank at a rate of 6-6e^(-.09t) liters/minute, where t is in minutes since the pump is started. If the holding tank contains 1000 liters of water when the pump is started, how much water does it hold one hour later??Round your answer to one decimal place.

- Let V(t) be the volume of water (in Liters) in the tank after t minutes. We are given that V(0) = 1000, and we wish to find V(60). We are also given the rate of change of the volume: V'(t) = -[6 - 6e^(-0.09t)]. Note that a negative sign needs to be placed because the rate represents water leaving the tank, i.e., being pumped out of the tank. By the Fundamental Theorem of Calculus, Integral (0 to 60) V'(t) dt = V(60) - V(0), so that V(60) = V(0) + Integral (0 to 60) V'(t) dt V(60) = V(0) + Integral (0 to 60) -[6 - 6e^(-0.09t)] dt V(60) = V(0) + Integral (0 to 60) [-6 + 6e^(-0.09t)] dt V(60) = V(0) + [-6t + (6/-0.09)e^(-0.09t)] (Evaluated at t = 60 - Evaluated at t = 0] V(60) = V(0) + [-6(60) + (6/-0.09)e^(-0.09(60))] - [-6(0) + (6/-0.09)e^(-0.09(0))] V(60) = 1000 + [-360 - (200/3)e^(-5.4)] - [0 - (200/3)] V(60) = 1000 - 360 + 200/3[1 - e^(-5.4)] V(60) = 640 + 200/3[1 - e^(-5.4)] V(60) = approx. 706.4 Therefore, approximately 706.4 L of water occupy the holding tank 1 hour after the pump is started.

- Q: One month ago, mechanics replaced water pump for my car, 04 dodge stratus, 100000 miles. When I went to get the car, there was big noise coming out from engine. The mechanics told me it was because of sediment in auto oil system and he show me some sediment he took out. I know little about car so I thought he was right. But now the noise changed and engine light came on. I went to firestone to check it. The report said timing jump and cranked. The second day the engine died totally. And I went to another two mechanics. They said the previous one who replaced the water pump did something wrong to timing chain. But that mechanics didn't admit it. What can I do?

- You're on thin ice with this, unless you had the timing belt replaced before 90,000 miles. That big noise was the pistons hitting the valves after the timing belt slipped, or more likely, broke from being worn out. When the engine's water pump is driven by the timing belt, the belt must be slacked to get the pump off, then tightened back up after the new pump installation. That old belt couldn't hold up under the tension. It's just bad luck for the mechanic he didn't think to question the age of the timing belt and insist that it be replaced. Of course that would cost a bit more. It will be an uphill battle. You might as well find a used engine if you want this car back on the road. Good luck to you.

- Q: i installed a new pump don't know how to increase water pressure and to what what pressure it should be set

- This is very simple i would sugest the pressure to be set betwene 60 to 70 NO MORE THAN 70. 1. turn off power to pump (ether the circut breaker or a switch near the pressure switch) you dont want to weld the wrench to the switch. 2. remove the cover to the pressure switch its self (usly one #2 phillips screw) 3. now you will see 4 wires under some sloted screws nearest to the front of the switch, behint that is 1 or 2 bolts with a spring and a nut. 4. if you see 2 bolts you will want to turn the nut on the larger one to the right. you will want to tighten it about 1 to 2 full turns. (the same goes if there is only one bolt also) 5. now open the valve that is on the tank untill you here the switch click. then close the valve. 6. turn the power back on tio the pump and watch the pressure gauge on the tank. i DO NOT RECOMEND MORE THAN 70PSI. 7. if it goes over the pressure you want repete steps above exept loosen the nut in about 1/4 to 1/2 turns untill you reach the desired pressure 8. if it does not reach your desired pressure then you do the same thing exept tighten the nut in 1/4 to 1/2 turns untill you attain your desired pressure. 9. when the pressure is reached, replace cover so you dont risk rusting the contacts. if you need more help feel free to email me. and i will assist you in any way that i can.

- Q: it is a mazda b3000 pick up v6,it is coming from behind water pump,but it is not all the time, i would think that if pump is going it would be all the time, but it will go bone dry for a few dayswhen it does leak it leaves about an 8 inch spot on the driveway,temp gauge goes to its regular spot and does not move,any suggestions would be helpful,thanks

- Not sure where it is coming from? I will speak slowly, and use small words. Gasket leaking. Replace. Pump may be bad.

- Q: I have a Honda 20003 bf15 d short shaft Ineed to change the water pump I have removed the 5 bolts that hold the lower unit it on but the shifter is steal hooked up how doI unhook that?

- Please get the workshop manual. From an imperfect memory it should be in forward gear to expose a link - but I could be confusing it with other brands. This brand has a known issue with the water pump if ever run dry as both the impellor and the housing can be damaged instantly. The pump should always be replaced as a full assembly, housing, seals and impellor, as detritus can easily block water galleries and that requires extensive work to remediate. The thermostat should be checked and replaced at the same time. Worn and damaged impellor material can easily end up through the block, head, thermostat etc. and that must be checked for as well. The lower cylinder can be down on compression caused by local overheating due to this and mud, sand and corrosion reducing water flow. An engine that very much must be flushed and looked after after all use - that includes all the larger models with this brand. They are quite a good engine, but seem very heavy for the output to me - particularly compared to lifting a two stroke on and off....

- Q: 1998 BMW 328i : to replace water pump, thermostat and gaskets, brake flush, fuel system cleaning with tune up,drive belt for 90k serivce; totally how much bucks?thx a lot !

- You will be lucky if you pay only $500. Plan on a GRAND...

- Q: What is the difference between a sewage pump and a clean water pump? Why can't sewage be pumped with clean water?

- The main difference between water pump and sewage pump is that:Impeller and runner design, as well as other parts of the configuration are very different.1., in order to prevent clogging of sewage pump, the main design of large flow channel, so naturally lead to relatively low efficiency, so the head is generally not high. Clear water pump flow smaller, smaller clearance, the head is relatively high.2. in order to prevent the wound, water pump impeller design is more simple but not ring pump, equipped with tips, cloth and other debris can be crushed after the pump, and the impeller water pump is relatively complex, but the efficiency will be significantly higher than the former.Why can't the sewage water pump and impeller: because features of key design, resulting in water pump for sewage situation is likely to occur, blocking, winding, wear and corrosion occurs, resulting in damage to pump or scrapped, so water pump can not be used for sewage.Sewage pump is a pump and motor conjoined, and at the same time submerged into the work of pump products, and general horizontal pump or vertical sewage pump compared to the sewage pump compact structure, small footprint.The water pump is for the transport of water and physical and chemical properties similar to water and other liquids used, suitable for the industry and the city water supply and drainage, water pressure high-rise buildings, garden sprinkler, fire booster, long-distance transportation, HVAC refrigeration cycle, irrigation, bathroom, cold and hot water circulation pressurization and equipment.

Send your message to us

Cast Iron Listed Fire Pump High Quality Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords