Cast Iron Control Panel Fire Pump High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

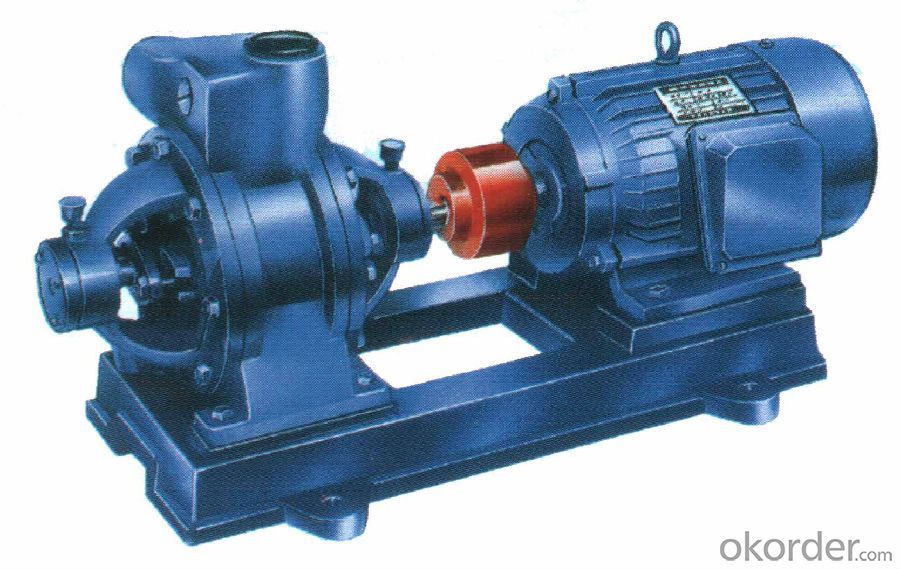

Cast Iron Control Panel Fire Pump High Quality

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product Parameters of Cast Iron Control Panel Fire Pump High Quality

| Capacity: | 20-200L/s |

| Head: | 0.3-1.28MPa |

| Speed: | 2900r/min、1450r/min |

| Power of fitted motor: | 0.75-250kW |

| Inler diameter: | 25-300mm(1"-12") |

Application Range of Cast Iron Control Panel Fire Pump High Quality

It is mainly used for the water supply for the fixed firefighting system of both industrial and civil building

fire hydrant fire-extinguishing system,

automatic spraying,

fire-extinguishing system.

Cast Iron Control Panel Fire Pump High Quality Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Picture Show

Why choose us

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q: What are the parameters of the pump price?

- The first point: brand, manufacturers are generally different, the price difference is relatively large, the brand effect and quality of this.The second point: motor model and matching pump model, the general power is greater, the higher the price.The third point: special requirements, such as: to achieve a special lift, or special flow, special materials, special maintenance period, the rate of special accidents. The price is higher than the usual model.Basically, these are the pumps that determine the price of the pump. In fact, the same manufacturer, the power difference is not too large, there is no special requirements, the price is basically the same, the reason manufacturers do not the same price, is a marketing strategy, in fact, the cost is the same.

- Q: I am trying to replace my old water pump with a new one. I have the quot;special tooland everything but i just cant get the water pump to come loose at all. Any suggestions would be helpful Thanks

- When you mean it wont come loose, do you mean you cant break the bolts loose or is the pump stuck on the motor like glue? If the bolts are stuck, try spray them with penetrating oil and let it work in for about 30 mins. If the pump is stuck, use a narrow putty knif, gently tap in between the pump and the block, and pry it off, then clean the mating surface completely to ensure the new pump seals properly.

- Q: as i asked before in my question what needs to be fixed when a water pump goes bad. so finally it went bad today the car leaked all coolant and for some reason all the blades on the fan broke and the battery light came on. which is connected to the alternator belt so thats not the problem. so now does anybody have any idea how much it would cost to fix and by what i know it needs a new belt for water pump and new fan and water pump etc. taking it to mechanic monday but wanna get an estimate first from u people. any ideass thanks

- Oh you found one doe 60 bucks good for you. Lot cheaper than the dealer quoted you. When a water pump job is done the fan and belt are removed anyways. So all you will have to buy is the new fan, the belt if you want. The other parts you listed are probably fine. The tech will inspect them when doing the water pump (if he's on top of things) and he'll let you know.

- Q: motor overheats but no leak. water just boils in resorvoir. is it hard to do it on my own?

- Water pumps have whats called a weep hole, if it's going the weep hole will leak coolant, Could be the belt on the waterpump is not tight eneough to turn the pully.

- Q: My car is 3 years old and it only has 18,000 miles on it and I just got it back from the repair shop at the dealership because the water pump broke. They replaced the water pump and something else that was recalled. But I looked online and found water pumps should last a long time. What might have happened to it, and what would cause it to break?

- There may be a few answers, one may be the bearings went or have worn out. However with only 18,000 mi. it hardly seams likely. Another is when the water or coolant does not have enough anti-freeze, not only for the winter time but also for the summer time. From freezing the pump to warping the parts in the pump when over heating.

- Q: how can i choose a water pump that is truely on demand as in shuts off when not needed automaticly i purchaced one that claimed it was a quot;demandpump is mine defective or not a true on demand pump?

- RV section is probably under cars and transportation, others. On demand pumps are quite common and used in many RV's.

- Q: What is the influence of the speed of the pump motor on the pump?

- Influence the parameters of pump flow and lift.

- Q: I have gotten oil in my coolant, and coolant in my oil..It might be the head gasket, no doubt, but many people said (online forums) that my bike, has issues with the seal that is separating oil pump from water pump. They go bad, and when they do, the oil mixes with coolant and vise versa. Now, I am seeking from professional help, on how to take out both of the pumps, without messing up timing, and also without messing up anything else. I have removed the entire exhaust system, dropped the oil pan, and i can see the oil/water pump pretty good. What i do not know is how to remove it properly. Any help is help, I have searched and searched on google and forums on how to perform this task, but couldnt find any specific help on how to remove the pump. Thank you!!!!!

- Yamaha Oil Pump

- Q: Replaced the water pump in my 89 f150 and now I have a pretty steady leak coming out. I don't know where the leak is coming from, but its running down the lower hose and dripping off it. I've replaced the lower hose and water pump, what could be causing this?

- could be anything, including loose lower radiator hose, backing plate for the waterpump(have gotten the things and the 2 bolts are loose and missing the gasket)get you a mirror and light, and start searching around it, did you do the thermostat?may have broken the housing, or pinched it.

- Q: We had a leak in our car and took it to get checked out. They said it is the water pump. Also that it would be around $650 to replace. I know nothing about cars. Is this necessary? and does the cost sound about right? We are going on a 3 hour trip one way this weekend. Would it need to be done before then? thanks guys!

- on cars with water pumps that run off the timing belt it can be pricey to replace. If its a vehicle that has a water pump running off the accessory belt it shouldn't be to much unless its a BMW or foreign. state what kind of car its for it could help us answer. also do the water pump before the trip, if its really bad then getting stranded will cost you alot more.

Send your message to us

Cast Iron Control Panel Fire Pump High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords