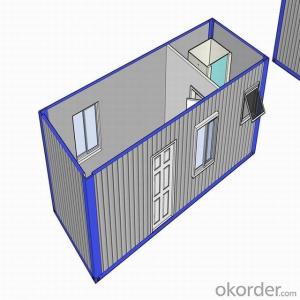

Beautiful container house

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Container House

cost-efficient, expandable in each direction, transportable

Container House

1. GENERAL

The standard container for various purposes is suitable for international container transport. It is of appropriate external dimensions and has connections for lifting and fixing or compounding. The container is designed as a light construction consisting of floor and roof frames and corner profiles. The construction enables compounding of individual containers in longitudinal and transverse directions without limits. It also enables compounding of containers in 2 floors in height (ground floor + first floor), or in 3 floors in height for warehousing of these containers (ground floor + 2 floor).

The wainscots of the container are made of light insulation panels and offer pleasant climate in the interior due to their building and physical properties.

Delivery: Containers can be delivered assembled or individually in kits 648 mm high.4 kits can be bundled in packages 2591 mm high (ISO dimensions)

2. DIMENSIONS and TARE (ISO Standard 1161)

-External length 20/(inner length) 20: 6.055m/(5.851m)

-External width/(inner width): 2.435m/(2.231m)

-External height/inner height: 2.790m/(2.510m)

-Tare: 1950 Kgs

3. STEEL FRAMEWORK

3.1 Material: cold formed steel profiles in a thickness of 3 to 4mm (bottom rails).

3.2 Surface working: electric galvanization min 15 μm, zinc compatible epoxy ground coat in a thickness of 30μm , final zinc compatible vinyl acrylic coat in a thickness of 60-70μm.

3.3 Fittings: 8 comer fittings (dimensions according to ISO standard 1161), rainwater pipe in the roof framework, plate thickness of 10mm excluding top corner fittings of the top kit of each bundle (20mm thickness)

3.4 Forklift openings: openings for fork-lift pockets in the floor framework, dim 88×250mm in a distance of 1200mm

4 .FLOOR

4.1 Composition:

-external wainscot: flat galvanized steel sheet metal in a thickness of 0.5mm.

-insulation filling: non combustible mineral wool in a thickness of 100 mm among steel transverse supports. Mineral wool density: 60 Kg/m3

-steam blockade: PE foil in a thickness of 80μm

- plywood panel in a thickness of 18mm

-glued PVC flooring covering in a thickness of 1.5mm.

4.2 Permitted loading : 2.50 KN/m2

4.3 Coefficient of thermal conductivity: l=0.039 W/mK

4.4 R value (Thermal Resistance) = 2.56 m2K/W

4.5 XPS insulation option: it is possible to choose an alternative insulation filling: extruded polystyrene (XPS) in a thickness of 80 mm among steel transverse supports.

XPS density :35 kgs/cubic meter

Coefficient of thermal conductivity: l=0.029 W/mK

R value (Thermal Resistance) = 2.76 m2K/W

5. CEILING:

5.1 Composition:

-external wainscot: flat galvanized and painted steel sheet metal in a thickness of 0.5mm.

-insulation filling: non combustible mineral wool in a thickness of 100mm among plywood purlins. Mineral wool density: 60 Kg/m3

-steam blockade: PE foil in a thickness of 80μm

-inner wainscot: chip wood panel in a thickness of 9 mm with a foil in white color; joining of chip wood panels with PVC profiles

5.2 Meteor water outlet: 4 each of PVC rainwater pipes, diameter 50mm in corner pillars

5.3 Permitted loading: 1.50 KN/m²

5.4 Coefficient of thermal conductivity: l=0.039 W/mK

5.5 R value (Thermal Resistance) = 2.56 m2K/W

6. FACADE WALLS

6.1 Side panels width: 1145mm; total panel thickness: 70mm.

Five panels fit into the long side and two panels fit into the short

side of container and they are fully interchangeable

6.2 Composition:

-External wainscot: galvanized and painted steel sheet metal in a thickness of 0.5mm.

-Insulation filling: non combustible mineral wool in a thickness of 50mm in the wood framework. Mineral wool density: 60 Kg/m3

-Inner wainscot: chip wood panel in a thickness of 9 mm with a foil in wood pattern (bright oak or white).

Joining of panels with PVC profiles. Final elements in the interior are made of chip wood panel in a thickness 8mm with a foil in wood pattern.

6.3 Permitted loading: 1.00 KN/m²

6.4 Coefficient of thermal conductivity: l=0.039 W/mK

6.5 R value (Thermal Resistance) = 1.28 m2K/W

6.6 100 mm insulation option: the framework can be modified so that mineral wool insulation reaches a thickness of 100mm. In this case R value (Thermal Resistance) goes up to: 2.56 m2K/W.

Note that 100 mm thick wall panels are not fully interchangeable like standard 50 mm ones

7. DOORS

Standard external door. Single fold, 40mm thick, made of:

· a frame in prepainted aluminum

· hot galvanized and prepainted steel sheets (inside and outside)

· insulated with PL (polystyrene)

Opening dimensions of 808×2030mm, furnished with a handle lock with 3 keys.

Net opening dimensions: 754 x 1985 mm.

Also 845 x 2000 mm net opening is available.

8. WINDOWS

8.1 Windows

Option 1: made of PVC, white color, with dimensions 800×1100mm, glazed with double layer glass in a thickness of 4/15/4mm, with sliding mechanism (one side fixed and one sliding)

Option 2: made of PVC, white color, with dimensions 800×1100mm, glazed with double layer glass in a thickness of 4/15/4mm, with tilt and swing mechanism

Option 3: made of PVC, white color, with dimensions 800×1200mm, glazed with double layer glass in a thickness of 4/15/4mm, with tilt and swing mechanism

8.2 Rolling shutters

Option 1: external PVC rolling shutters in PVC guides.

Option 2: external Aluminum rolling shutters without insulation in Aluminum guides.

Option 3: external Aluminum rolling shutters with insulation in Aluminum guides.

9. ELECTRICAL INSTALLATIONS

9.1 Standard: according to VDE 100 and CE regulations

9.2 Voltage: 220 V, 60 Hz single phase

9.3 Network connections: CEE-connection plus/socket, 3-pole 32 A, 220V, mounted on the top frame in upper corners of a shorter side wall

9.4 Inner distribution system: BVVB cables of suitable dimensions (6, 2.5, 1.5 mm) ,CE marked , flush-mounted.

All cables (located on the ceiling and inside wall panels) run into CE certified plastic conduits. Roof cables and panel cables are connected with CE compliant jacks. All jack connections are protected inside CE marked and IP44 rated distribution boxes.

9.5 Protection: protective current switch (40/2E-0,03A), automatic fuses (B-characteristics) of suitable power (10A, 16A)

9.6 Earthing: galvanized connector with a steel plate of

dimensions 30x80mm welded on the bottom frame

- Q: Are container houses suitable for people with disabilities?

- Depending on their specific needs and the modifications made to the container, container houses may be suitable for individuals with disabilities. The versatility and adaptability of container houses are one of their advantages. They can be personalized to meet the individual requirements of people with disabilities. For instance, ramps or lifts can be installed for wheelchair accessibility, doorways can be widened to accommodate mobility aids, and grab bars can be added to bathrooms for increased safety. Furthermore, container houses can be designed with open floor plans, providing ample space for easy movement and navigation for individuals with limited mobility. These open spaces also allow for customization and the installation of assistive devices like handrails or hoists to aid in daily activities. In addition, container houses can be designed to be energy-efficient and environmentally friendly, which can be beneficial for individuals with disabilities who have limited resources or specific environmental needs for their well-being. However, it is important to note that the suitability of container houses for people with disabilities depends on the specific disability and level of support required. Individuals with severe mobility impairments or those who need extensive medical equipment may find it challenging to adapt to the limited space and structural limitations of container houses. To conclude, container houses can be a viable option for people with disabilities if the necessary modifications and adaptations are made to accommodate their specific needs. It is crucial to consider the individual's unique requirements and consult experts or professionals in accessible design to ensure that container houses meet the required accessibility standards.

- Q: Can container houses be designed to have a skylight or large windows?

- Container houses have the potential to feature skylights or large windows. Numerous architects and designers are currently integrating skylights and large windows into their container house designs to optimize natural light and establish a feeling of openness. Ample sunlight can infiltrate the interior space by installing skylights on the container's roof. Furthermore, panoramic views and improved aesthetics can be achieved by incorporating large windows into the side walls of the container. Additionally, the utilization of skylights and large windows can enhance ventilation, diminish the requirement for artificial lighting during daylight hours, and contribute to the energy efficiency and sustainability of container houses.

- Q: Are container houses suitable for permanent or temporary living?

- Container houses can be suitable for both permanent and temporary living, depending on individual needs and preferences. For temporary living, container houses offer a cost-effective and flexible solution. They can be easily transported and set up in different locations, making them ideal for people who frequently move or need temporary accommodations, such as construction sites or disaster relief efforts. On the other hand, container houses can also be suitable for permanent living. With proper insulation, plumbing, and electricity installations, container houses can provide all the necessary amenities for a comfortable and functional home. They can be customized to meet the specific requirements and aesthetic preferences of individuals or families, offering a unique living space. Container houses also have several advantages for permanent living. They are eco-friendly as they repurpose used shipping containers, which reduces environmental impact. Additionally, container houses are often more affordable than traditional houses, making homeownership more accessible to a wider range of people. However, it is important to consider some potential limitations of container houses for permanent living. The limited size of shipping containers may pose challenges for larger families or individuals who require more space. Modifying containers to meet building codes and regulations may also involve additional costs and time. Furthermore, the industrial look of container houses may not appeal to everyone's aesthetic preferences. In conclusion, container houses can be suitable for both permanent and temporary living, depending on individual needs and preferences. They offer cost-effectiveness, flexibility, and eco-friendliness, making them a viable option for various living situations. However, it is crucial to carefully consider the specific requirements and limitations of container houses before deciding on their suitability for a particular living arrangement.

- Q: Can container houses be designed with open floor plans?

- Certainly, open floor plans can be incorporated into container houses. The adaptability of shipping containers as construction materials offers numerous design possibilities, one of which is the option for open floor plans. By eliminating walls or incorporating sliding doors, container houses can achieve a generous and expansive layout that maximizes the available area. Furthermore, these houses can be tailored to meet the unique requirements and desires of the homeowners, enabling the creation of a practical and visually appealing open floor plan.

- Q: Can container houses be designed to have a small carbon footprint?

- Yes, container houses can be designed to have a small carbon footprint. By implementing eco-friendly materials, such as recycled insulation and sustainable flooring, and incorporating energy-efficient features like solar panels and rainwater harvesting systems, container houses can significantly reduce their environmental impact. Additionally, proper orientation and ventilation can optimize natural lighting and cooling, minimizing the need for excessive energy consumption. Overall, with thoughtful design and conscious choices, container houses can be an excellent option for sustainable and low-carbon living.

- Q: Can container houses be designed with a built-in bookshelf or library?

- Yes, container houses can definitely be designed with a built-in bookshelf or library. The versatility of container homes allows for creative and functional interior design solutions, including the incorporation of bookshelves or even entire libraries. These features can be customized and integrated into the container's layout, making it a cozy and unique space for avid readers or collectors of books.

- Q: Can container houses be financed or insured?

- Yes, container houses can be financed and insured. Many banks and financial institutions offer loans specifically for alternative housing options like container houses. These loans typically have similar terms and conditions to traditional mortgages. As for insurance, container houses can be insured just like any other type of residential property. However, it is important to note that insurance companies may have specific requirements or considerations for insuring container houses. Factors such as the construction quality, location, and safety features may impact the availability and cost of insurance coverage. It is advisable to consult with a professional insurance agent or broker who specializes in alternative housing options to ensure that you are adequately covered. They can guide you through the process and help you find the right insurance coverage for your container house.

- Q: Are container houses suitable for areas with limited access to construction materials?

- Yes, container houses are suitable for areas with limited access to construction materials. Container houses are constructed using shipping containers, which are readily available and can be transported to remote locations more easily than traditional construction materials. Additionally, container houses can be designed to be self-sufficient and eco-friendly, reducing the need for additional construction materials and resources.

- Q: How is the container housing made and installed?

- Buy finished product box restructuring, that is, in the box on the hole installed on the doors and windows

- Q: Are container houses subject to building codes and regulations?

- Container houses must adhere to building codes and regulations, despite their unique construction. These structures are subject to the same rules as traditional homes or buildings. The specific regulations may differ depending on the location, but they typically encompass safety, structural integrity, energy efficiency, fire protection, electrical and plumbing systems, and occupancy standards. Given that container houses are often created from repurposed shipping containers, adjustments may be necessary to meet the building code criteria. It is crucial to consult with local authorities or engage a professional architect or engineer to guarantee compliance with all regulations and to obtain the necessary permits before starting construction or occupancy.

Send your message to us

Beautiful container house

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords