Ball Valve For Heating SupplyDN 10 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

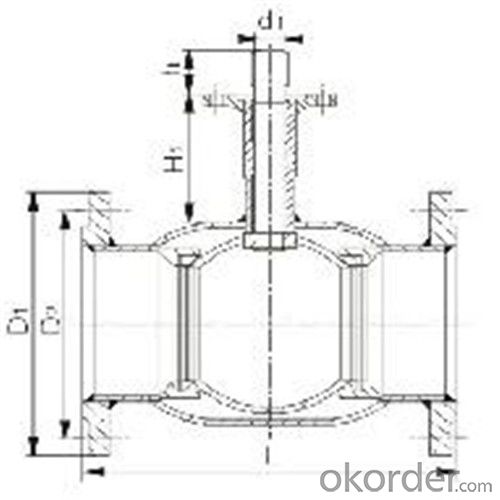

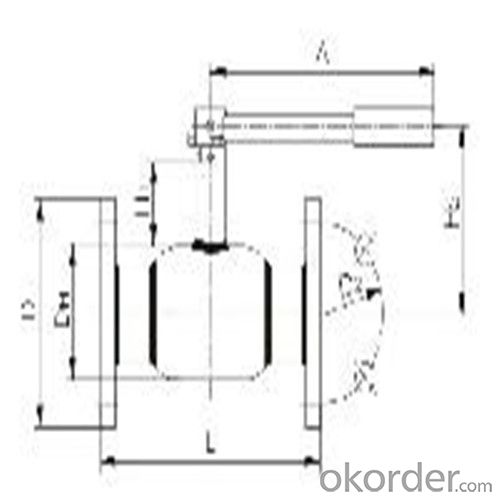

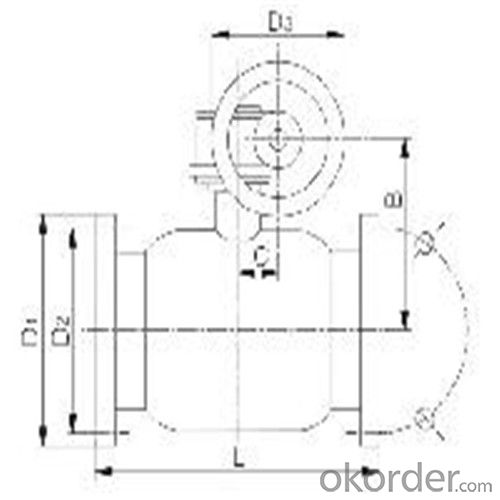

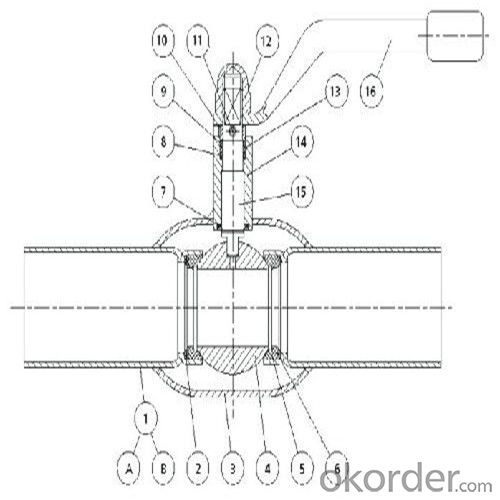

Product Description of Ball valve for heating supply:

Technical introduction

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Ok so I have a Honda Civic 97 lx and what happened was that when I did an oil change the next day the car started over heating, the car only had pure water and no coolant, the over heating part happened during noon when I was driving on the freeway the next day and not the night I made the oil change... After that I decided to put 50/50 coolant but the car still over heats, a friend told me that I probably needed to do a coolant system bleed, I try to do it but I couldn't find the bleeding valve or bleed screw... can anyone pls tell me where that valve or screw is located, I discovered a sort of valve that is covered by a black rubber cap , its next to the engine I don't know if that's what I'm looking for.....

- You can also get a good bit of the air out by removing one end of the upper radiator hose from the car and filling it with antifreeze. I recently had a 93 Civic in my shop that DID have a bleeder valve on it. If your car does the person above gave you the correct method of bleeding it.

- Q: I got a 2012 peterbilt 386 ...it just came back from the shop a few day ago to get injectors 4 and 5 looked at and repaired ....I'm getting a fault code for injector spill valve and a engine light ....I tried resetting the computer to get rid of the code but that's not it ... uld timeing of this cause the problem ...but other than that it runs like a champ so what could I do to fix this is it time cause I did probably get re timed when they repaired it

- The fault for the spill valve is not something you can correct with timing. When they repaired or replace injectors they need to be programed into the computer so they match the other injectors. The spill valve is in the injector and is there to return unneeded fuel back to tank. If this valve does not work you could be over fueling or run the risk of fuel cooking in the injector making a mess of the spray pattern. It should be telling you which injector is throwing the code and if it is one of the two that were worked on take it back.

- Q: For example, 2 valves from the modular 4.6 is equivalent to 1 valve from the LS1 which is a bigger valve.

- Yes, because the largest 4 valves one can cram in the same cylinder head are smaller BUT provide more area than the largest two valves that would fit in the same head. With valves, the larger the overall area, the better.

- Q: my valves got dirty long story how do you clean them

- Remove the valves, wash them and the horn in warm (NOT hot) water with liquid dish soap. Dry with a clean towel, then oil and reassemble.

- Q: 1999 Mercury Cougar in awesome shape no engine problems, and has just under 86000 miles. I bought it recently and the check engine light came on out of nowhere and I realized It was an EGR issue the code was p0401 insufficient flow. I had a mechanic replace the solenoid valve as well as clean all of the carbon gunk off the valve and the light was off, then suddenly POPPED back on, making me really nervous and kind of upset. So today I had a few errands to run and I said I wasn't going to go get it read again until tomorrow, and it just Went off. So Is the car just very sensitive to things and is that why it goes on and off? Or is something wrong? I'm a student who really wants to keep this car nice like I bought it.

- believe it or not a gas cap being too loose can make many check engine lights come on. Make sure you get it tight when you fill it. Make it click click click That could give that kind of code too, because the fuel system needs to be pressurized. If it isnt, you get a weird code.

- Q: i bought thie air connector kit and it has y-valves, suction cups and air control valves, what are the air control valves for?

- The air control valve is for doing exactly what the name implies: controlling the air flow. IT allows you to reduce and regulate the flow of air as needed. They are super handy on multi-tank systems where tanks with shorter air lines get more air and need to be turned down to equalize all the tanks. They are also handy if you are running multiple air stones or air driven decorations off the same pump as it allows you to adjust flow to each device so one it not overpowered and other lacking in flow. The air check valve is the one that prevents water from heading back down the line in a power failure. A air control valve could do this, but you would have to manually turn it to off so the water didn't flow back, where a check valve is automatic and needs no human intervention.

- Q: so here are the details. i've been using my trumpet for about 6-8 years now and 1 if not 2 valves get stuck on my trumpet. the problem is not the oil as i have over oiled them too and no go. its that when i try to put my valves back in their place and twist them they don't stay in place,move ,and making either my valves stuck or making my trumpet not do a sound. what should i do? repair shop or buy a new one? i hear the clicking sound when i put them back but still all that does is either make my valve more sticky

- You really need valve oil I have used olive oil in a pinch

- Q: I need to make a one way valve that would allow water or other fluid one way but if there is too much pressure on the opposite side the valve will close and stop water from flowing backward. Can anyone help?

- R V parts stores have an item which allows a garden hose to be connected to the RV but the tank water inside the RV is not allowed to come out of the RV and enter the water hose (supply) so only fresh water comes in, nothing goes out.

- Q: My friend is having 3 valves in her heart replaced with pig valves. Her dr said that putting in human valves raises the risk of her body rejecting them but wouldnt your body also reject a part form different species? And if they only last a few years why use them at all? shes all freaked out about the surgery so I dont want to ask her too many questions

- Hello again. The valve I have implanted in me is porcine. Pig valves are sometimes used for a few reasons. First of all, they are much easier to get a hold of. Waiting for a human valve can take a long time. Secondly, there is less risk of rejection. These two reasons make a porcine valve better than having a human valve. You can also have metal valves, but when you have one or more of these you must take crazy medications for your entire life. With porcine valves, no extra medications are needed. So, porcine valves are really the best option. Like I said in a previous answer to one of your questions, I had my surgery when I was 16. I'm 22 now and doing alright. My valve is expected to last 10-15 years, so I expect to go under the knife to have it replaced when I'm 26-31. Unfortunately I have other issues and will have to have the surgery done earlier, and they'll probably change the valve while they're in there already. As far as I know, porcine valves last just as long as human valves. Whichever you have, it's going to clog up eventually anyways.

- Q: Can I make a heat pump straight A/C ?Or some hints how to replace the reversing valve without reclaiming freon

- something you would possibly want to do is tap the valve without making a dent. that's accessible it basically were given stuck. once you've a volt/ohm meter be sure that's getting skill. If it isn't basically save on with the strains decrease back till you discover the position the skill stops contained in the electric powered strains. it would want to also be a foul solenoid on the valve. in case you get better information, submit it. solid success.

Send your message to us

Ball Valve For Heating SupplyDN 10 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords