Ball Valve For Heating SupplyDN 50 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

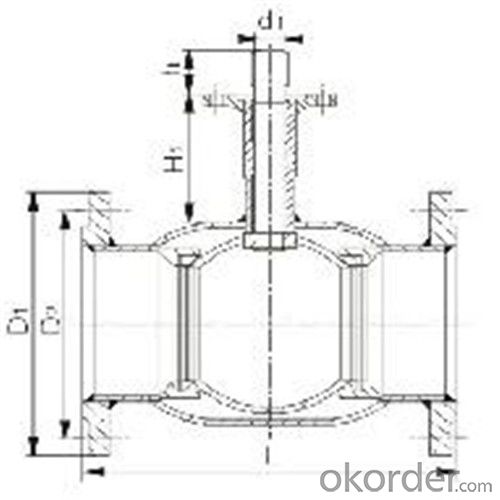

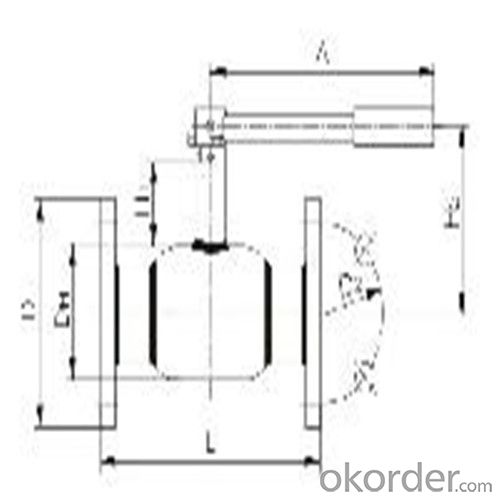

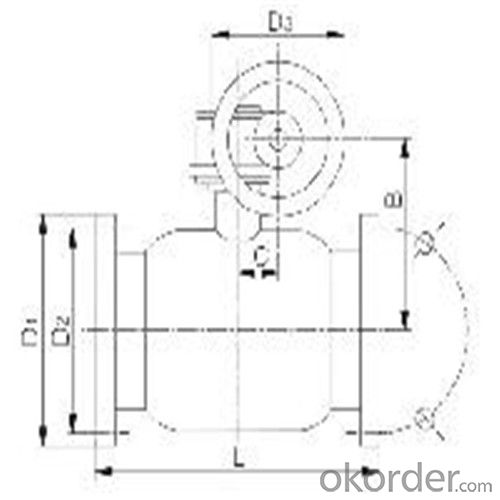

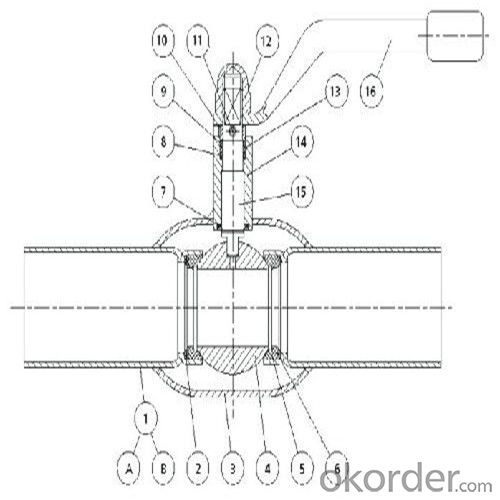

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Hi i have a 00 bmw 320d and am trying to find out information on puting a dump valve in, is it possible?, what type of dump valve? and how hard it would be to put in?? any help would be much appreciated.....Thanks!!

- Dump Valve Diesel

- Q: the blow off valve has a hose that goes to the intake. Do you need that hose.

- if you want it to operate properly the yes you will need it. The valves are also adustable but you need a tech manual to and special tool to do it propperly dont just guess at its setting rather know it. I assume the picture i looked at was your engine. Unless you like taking chaces i would recomend you put your timing belt cover back in place. If anything should get in there between your t-belt and gears or pullys the belt could be damaged and if it does get damaged you could damage the valves in the event of t-belt failure. I know people like to see the belt and gears moving and if that is what you are wanting i would suggest installing one of the clear t-belt covers that are available. unfortunatly i do not know who makes them. if you cant find out go to a car show and talk to gear heads that have them on there cars.

- Q: hii have just found out i have a genetic disease called multi valve prolapse but i want more info about itwhat are the symptoms? can it kill me? any info will help!!thank you

- Do you mean Mitral valve prolapse? The mitral valve helps blood on the left side of the heart flow in one direction. It closes to keep blood from moving backwards when the heart beats (contracts). Mitral valve prolapse is the term used when the valve does not close properly. It can be caused by many different things. Most people have no symptoms, but some people have chest pain, a rapid pulse, awareness of heartbeats, migraine headaches, fatigue, and dizziness. In a small number of cases, the prolapse can cause blood to leak backwards. This is called mitral regurgitation. Mitral valves that are structurally abnormal can raise the risk for bacterial infection. Some forms of mitral valve prolapse seem to be passed down through families (inherited). Mitral valve prolapse has been associated with other genetic disorders.

- Q: When my son was three I switched Dr's for him. The new doctor said has he always had a heart murmur I said no that's the first I've heard of it so we went for test. Anyway heart specialist did all tests said my son had Bav a valve disorder in the heart. He said it is very common. However everyone I've ever talked to has never heard of it. My question is does anyone have this what is your story and have you had to have your valve replaced. My son is very healthy active I'm just worried. Any help would be greatly appreciated....thank you!!

- A bicuspid aortic valve is not necessarily a problem - a normal aortic valve has three cusps, and your son only has two. Having only two cusps is not a big deal. The mitral valve in the heart naturally has only two cusps, so three cusps are not needed for a heart valve to function. The advantage of three valves is a slight increase in efficiency, but the difference between a normal valve and properly working bicuspid valve would only matter to a professional athlete. If the aortic valve closes almost completely, there is nothing to worry about. Since he has a heart murmur, its possible that it is caused by having only two cusps, but people with three cusps commonly have murmurs. There is no reason to get the valve replaced simply because of only two cusps. What matters is the level of aortic valve regurgitation. If regurgitation is not significant, your son has a normally functioning heart. Even if he had a moderate or high amount of regurgitation, it still might not have enough effect to warrant surgery. There are tests to measure regurgitation.

- Q: I want to put a blow off valve in my car to make it sound cool lol but i dont have a turbo yet ... do i even need one?

- look on youtube theres a way but its a very getto way lol. there youtube user name is mightycarmods

- Q: what exactly is thc pcv valve and what does it do

- The positive crankcase venitlation (PCV) valve allows a vent for gases which naturally buid up in an engine. In the 60's, it was vented out into the atmosphere. California Air Resources Board (CARB) passed legislation stopping the practice. Instead of venting, it now burns through the normal combustion process. The PCV valve regulates how much is allowed to pass through, because, at idle, if too much is allowed to go into the engine, a rough idle or stalling would occur.

- Q: primary function of a valve position?

- I am within the equal concern as you are in proper now. What I do, is 1) get headphones and 2) shut your door (if viable). Additionally set the sport sound reduce so that you could hear when your mother or dad is coming. In case your mom would not mean you can play considering of violence like blood, there's a strategy to disable blood/gore create an autoexec.Cfg add violence_agibs zero violence_hgibs zero violence_hblood 0 violence_ablood 0 It sucks to have these kind of dad and mom If nothing else works, are trying different games reminiscent of diablo 2, or oblivion or anything. Just right luck!

- Q: I had heart surgery a little over a year ago. This surgery gave me an artificial aortic valve in replacement to my real aortic valve. Before this I smoked weed all the time, but now, I 'm on blood thinners, and I'm not sure if it's okay. Is it?

- Ryan...I okorder /

- Q: i have a yamaha trumpet. i got it brand new and it is 3 years old. I recently did drop it and i have a tiny dent on the last turn to the bell. after that they started sticking . There are no dents on the valves or casing surrounding them. i brought them to Quinlan and fabish and showed them the sticking they replaced the valves spring padding and the such. They also did an ultrasound cleaning i think it is called . they are still sticking. Please any think that you can suggest i showed my band teacher who suggested going to Quinlan and fabish. Then my trumpet teacher who said i need to oil more after the cleaning please help

- Check that you are not putting sideways pressure on your valves when you press them downwards. Even on a good horn this sideways pressure can cause friction between the piston and the valve casing. Avoid this by arching your fingers a little, depressing with your finger's tips, and avoid the pinkie finger ring entirely. Tying your pinkie up in that only restricts your 3rd. finger's freedom of straight downward movement. Over- lubricating the valves can be as bad as too little oil. Do the whole warm bath treatment that you would normally do to clean it, add 3 drops to each valve, work horn for a few minutes, wipe valves with very old (washed heaps of times) t-shirt: then finally 2 drops again. If this doesn't work, get a trumpet specialist teacher to take it home for this treatment.(You might not be bathing it right). Failing that, check my web site's repair section. Good Luck!

- Q: we are having diffaculty with our spa and our jacuzzi. sometimes when we try and heat the spa the pool gets heated.first of all we would like to make sure the valve diagram is right because sometimes also the spa dumps about half into the pool. frustfrated can any one help?

- You have one or more faulty valves or you've got them turned the wrong way for the operation you want. You also may have a check valve that's going bad. The problem is that I'd have to see the setup around the pump and filter to even get an idea of what goes where. My pool has electric activators for the valves that allow automatic operation from inside the house. I adjusted one incorrectly once and it activated the valve backwards, and I had to readjust it.

Send your message to us

Ball Valve For Heating SupplyDN 50 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords