Ball Valve For Heating SupplyDN 20 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

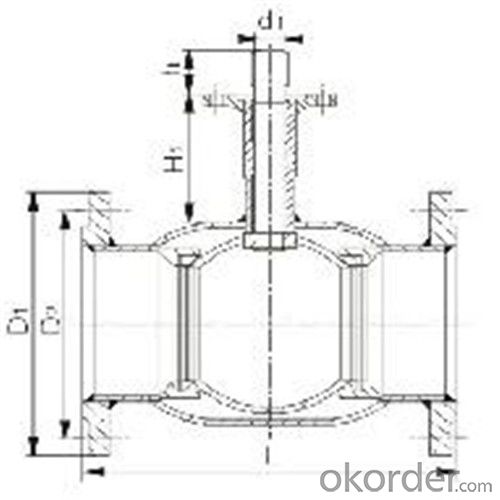

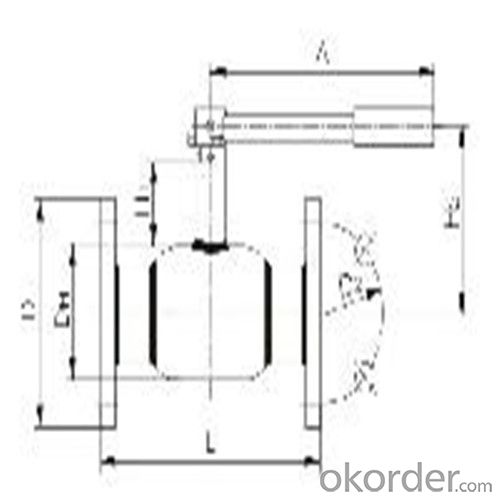

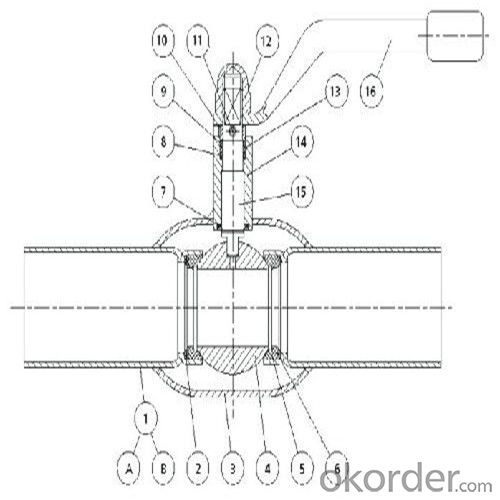

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

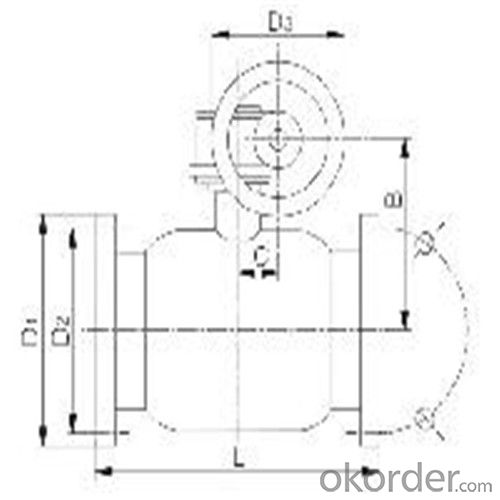

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: It is burning oil, so that means oil is getting into the combustion chambers....but im not exactly sure which piece has gone bad? or for that matter what the valve guides are in the first place. Could the lifters have gone bad too? Can someone tell me what piece is most likely the cause for the oil leak into the chambers and then a price of how much it would cost to have it fixed. When i start the car it blows a puff and then settles down and then when im at a stop light and push the accelerator it blows a puff and then more or less settles down...sometimes it keeps going for a while. My mechanic put an additive in the oil called stop the smoke or something, and i know that that causes the seals to expand...and it has helped. So. I need someone to give me an overall diagnosis and price range. My mechanic is reluctant to have me do the work, im guessing cause its expensive...but i would rather pay 1000 dollars then buy a new car.

- yes we would love to help, except you gave us zero information, in order to even begin to guess whats going on, you need to explain a whole bunch of information if you want any help, like what year make model of car, engine mileage on engine, and any other things that have been done to a coar that you know of. If you have a chevy 350 it was pretty normal to get a puff of smoke out if it when it was cold, this was from worn valve stem seals, and sometimes the design of the seal was a problem, like the umbrella seal for late 80s early 90s, even new some got a few drips of oil and blow a puff of smoke, you say its smoking out the tail pipe, ok when only when cold? or all the time , or under acceleration? when, that is the first clue we need to know ok?

- Q: OK, I would like to run my shorty headers open on my Camaro, but I have two questions.1. I heard valve damage may occur because cold air gets in there. Why isn't this the case with straight pipe exhaust, doesn't the cold air travel to the valves in that case anyway?2. Right now with my headers to off road y pipe I have 2 o2 sensors to throw the check engine light off, and it has worked. If I run open headers, will they still work?

- The valve damage from open headers sounds more like a theory than reality. I, and numerous other drag racers, have run open headers for decades without valve damage. More often than not, it's either the lower end or other parts of the valve train that crap out long before the valves. The O2 sensors will work if they stay hot enough, otherwise you may need to put heated sensors in.

- Q: Is there a way to test the EGR valve to see if its still good ? and working right .

- Yes there is. Disconnect the rubber hose on top of the EGR valve. Connect a hand-held vacuum pump to this fitting. Start the engine. Slowly apply vacuum to the fitting on the valve. While applying vacuum with the engine running at idle speed, the idle speed should drop or the engine may even stall. In that case the valve is working. If the engine speed doesn't change, the EGR valve may be defective, or EGR tube may be plugged with carbon, or the passages in the intake and exhaust manifolds may be plugged with carbon. In this case remove the EGR valve from the engine. Again apply vacuum to the EGR valve and observe the stem on the EGR valve. If the stem is moving, it can be assumed that the EGR valve is ok. In that case clean the EGR tube and the intake and exhaust manifolds passages Hope this will help you.

- Q: My car may have warped valves. What does this mean? Can it be fixed? If so about how much? And how does this happen in the first place? Anything helps! Thanks!

- who told you that? valves don,t warp. valves can bend and carbon up so much they won,t seat but they don,t warp. pull the heads and have new valves put in or have your valves ground and seated. a good machine shop can do that for you.

- Q: Is there anyway, from home, that I could rule out a bad heart valve as the cause for my heart palpitations and arythmia?

- As a physician, I strongly recommend you to visit a ER (Emergency Room if you were from UK) and explain the doctor what is going on. I also would recommended ACE inhibitors, since they prevent cardiac muscle remodelling. I can think in several other things, but I need PE and a new echo-cardiogram to make a decision (indeed a ER doctor must make those decision)

- Q: I want to switch off the water in the bathroom only due to replacing sink taps, will water still come out of the pipe if i turn the stop valve

- Assuming that the stop valves are good, turning them off will stop the flow of water to the sink taps. To test them, turn on the water faucet at the sink, then turn off both stop valves. The water should stop coming out of the faucet. If it continues to drip, the stop valves are defective and should be replaced when you do the job. If this is the case you'll have to shut off the main water valve or a valve upstream of the stops to replace them. Good Luck

- Q: I have a 04 Ford Ranger 4.0L . some people are saying that headers may affect the EGR valves and might put up the check engine light on. is this true or not.

- It depends on the headers. Some headers are setup with EGR hookups and others do away with them. So you need to check to see if the ones you are looking at retain the EGR and if they do you should have no problems. Also you might have to check the bolts weekly, some headers will get lose over time while others don't.

- Q: I have presta valves on my mountain bike now and only Presta valves can fit through the hole in the rim where the valve goes. If i want to start using Shrader valve tubes, because they are way more common and i can get them at Walmart, is it ok if i bore out the hole in my rim in order to get the Shrader valve to fit

- Yes you can. Many people have done so. Make sure you file the hole after drilling so you will not have any burrs. BTW most tubes come from China so if you want to put in walmart specials or from a reputable bike shop it will do the job. If you want to put presta valves again, then you can buy a grommet that reduces the hole size. If you have an expensive bike and want to keep it original, then I advise not to drill

- Q: Sohc ZC (d15) honda I'm going to be painting my valve cover am I going to need new seals? What do I need to take it off and put it back on ? Please help I have the high temp sand paper all ready to go I just want to be ready

- if i were you i would replace the gasket ! even if it don,t break taking it off it,s best to put a new gasket on when you pull the valve pan !

- Q: we are having diffaculty with our spa and our jacuzzi. sometimes when we try and heat the spa the pool gets heated.first of all we would like to make sure the valve diagram is right because sometimes also the spa dumps about half into the pool. frustfrated can any one help?

- You have one or more faulty valves or you've got them turned the wrong way for the operation you want. You also may have a check valve that's going bad. The problem is that I'd have to see the setup around the pump and filter to even get an idea of what goes where. My pool has electric activators for the valves that allow automatic operation from inside the house. I adjusted one incorrectly once and it activated the valve backwards, and I had to readjust it.

Send your message to us

Ball Valve For Heating SupplyDN 20 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords