Swing Check Valve Wafer Type Double PN 2.5 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

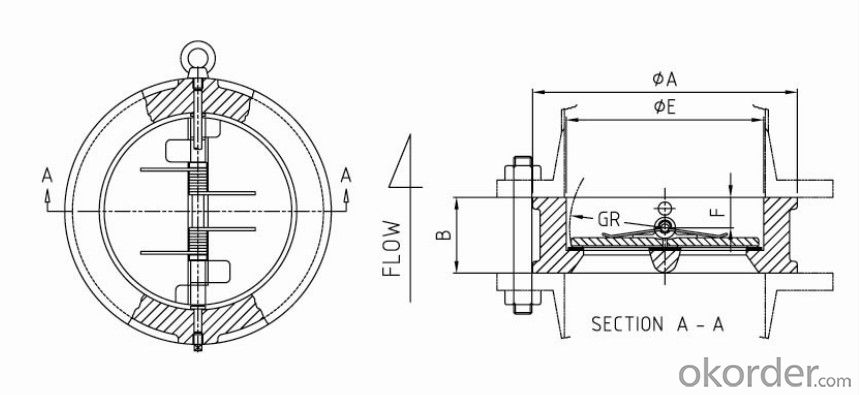

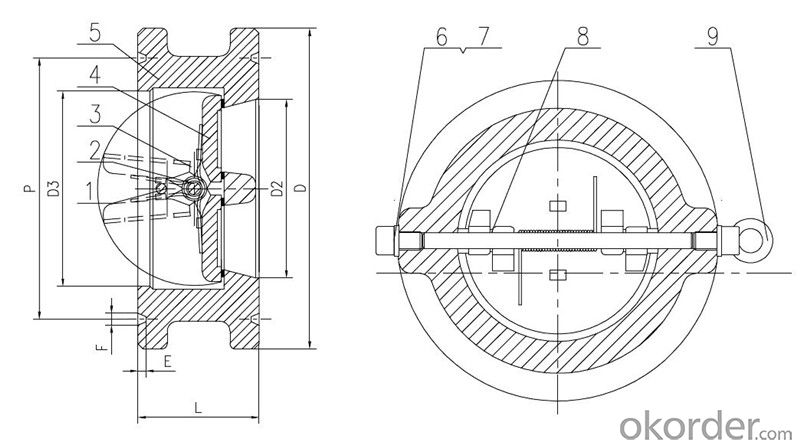

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

- Q: I have a mountain bike that my brothers left me. the tire in the front is a normal s valve, the one in the back is a presta valve. now this was ok because it was fully pumped up, but then it popped on the road, so i got a new tire ad put it on and was all ready to pump it up but when i tried to pump it no air would go in. so i looked at it a while and i figured out the top unscrews, so i unscrewed it and put the pump back on and started pumping, but after a while i figured out that no air was going in the tire and now i'm very confused.

- A presta valve can be a little finicky. If you don't push the pump nozzle down far enough, it won't let the air into the tube. Unscrew the valve, line up the pump head with the valve stem, push down firmly while twisting back and forth. Try pumping; if it builds up pressure, just push it down until it releases into the tire. Don't forget to pull up the lever on the pump nozzle.

- Q: A reading from my 2002 ford explorer said insufficient flow from the EGR valve. Would it be possible to clean the valve or fix it or would I need to buy a whole new valve?

- I have replaced several DPFE's for this reason. Never had to replace an EGR valve for the insufficient flow code. Like previously posted best to get a genuine Ford DPFE

- Q: Hello all,I have a1990,BMW 525i.I bought this car from another guy about year back and drive around 13000 kms.1.Do i need to adjust the valves(both inlet and outlet).2What is the importance of valve adjustment3Does it affect the mileage4.As a regular maintenance for how many kms can i drive without valve adjustmentExpecting your valuable replies.

- um...yes, no,,no and yes. no really all i know is correct clearance is important and if incorrect, it can do some damage. it does affect mileage, and both intake and exhaust need adjustment and i would recommend a professional technician. it is sometimes difficult for even a pro to adjust valves. i don't do it often at work, but had some trouble on my own car. had to remove the cover and change a couple cuz they were noisy after made the first adjustment.

- Q: My pressure reducing valve has gone bad. This looks like a pretty simple change. My question is do i loosen the union nut first (after draining water line), then loosen the whole valve??? Then reverse to install??? Any info would be great....

- Sometimes a valve can get something stuck in the valve like rust or sand and just need flushing. The reason you have a pressure reducing valve is because of the high main pressure. If you have a tight system it will build up pressure even if the valve is good if you do not have an expansion tank for your hot water tank this will also make your water heater vent about a quarter cup most every time it fires up if no faucets are leaking. You need to know how to shut off the pressure from the main. Then you are right it is simple to change the valve. The city has crazy pipe threads that you can't get but I don't think they would be on your pressure regulator Some cities have smart meters and I think they may know when you shut the valve off to the meter. Some one may be out to see why the meter stopped. The cut off valve and the meter belongs to the city or water provider in most places. Most cities do not want you to operate their valve

- Q: I think I have a bad valve steam seals because when I start the car white-grayish smoke comes out of the back of the car. When let sit for 2 or more hours start car and smoke comes out everytime. Will a valve adjusment fix the problem? Thanks

- I agree with MC. If you have a leaking valve seal, it'll just be a matter of time before the other ones start leaking, if it's a high mileage engine. You might as well pull the head(s) and have all seals replaced. The kit you but has all the seals in it, not just one. You can check the valves also while the heads are off.

- Q: I have a 2001 Ford Ranger with a 4.0 V6. I recently broke the valve cover bolt on the top right hand corner of the passenger valve cover ( the bolt closest to the belt). 1. Can I drive it like this and since 7 of the 8 bolts are in it should it leak worse. 2. How do I fix it, and 3. How much would this cost to have fixed if I took it somewhere. Thanks for your help

- Valve Cover Bolts

- Q: adjusting the overhead valves on briggs and stranton 14.5 engine

- Roll the engine over until the valve is completely closed. You can do this by watching the valve close, then turn the engine over until it just strats to raise. Now turn it back half way. Now losen the rocker arm and place a .003mm to .005mm filler gage between the push rod and the rocker. Tighten the rocker arm nut down so that the filler gage pulls out with a light drag. Do this with the other rocker and you are good to go.

- Q: hello I am having trouble inflating my back wheel tube. so i guess i will just tell you what happened. well i came back from the bike shop with a presta valve adapter and i put it on my tube. it fills up too near full psi but just after a ride around the block it is flat. i have no idea why. please help me! also its a mavic tube 700 x 23, vittoria rubino pro 700 x 23 tire, and a vuelta xrp 17 deep v back wheel. thanks!

- OK, okorder /

- Q: How hard and expensive is it to replace a pvc valve , hose, filter on 1991 Dodge Caravan 4 cylinder

- THE GUY ABOVE TOTALLY MISSED IT. IT IS VERY SIMPLE TO REPLACE AND SHOULD COST LESS THAN $25.00.

- Q: Can someone please explain the difference between a pressure tap valve and a gate valve (if any).

- For the last 60 years they are the same. Anyone that tells you differently is not telling the truth.

Send your message to us

Swing Check Valve Wafer Type Double PN 2.5 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords