Swing Check Valve Wafer Type Double PN 4 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

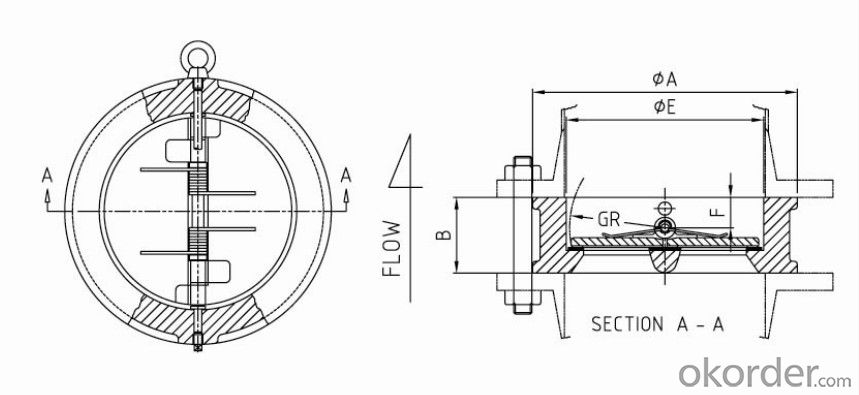

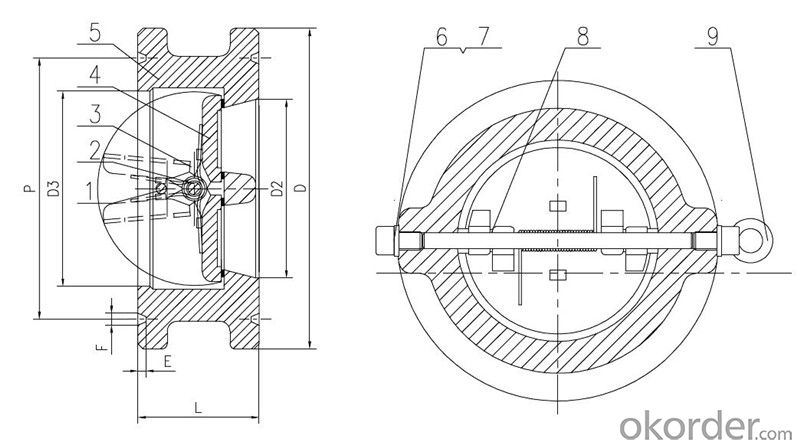

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I am trying to replace a leaky valve stem. And I didn't know how to get to the valve core and when I get there how do I change it? The charge is recovered. It is a 2000 Impala. Thanks in advance.Noah

- Schrader Valve Core

- Q: It is burning oil, so that means oil is getting into the combustion chambers....but im not exactly sure which piece has gone bad? or for that matter what the valve guides are in the first place. Could the lifters have gone bad too? Can someone tell me what piece is most likely the cause for the oil leak into the chambers and then a price of how much it would cost to have it fixed. When i start the car it blows a puff and then settles down and then when im at a stop light and push the accelerator it blows a puff and then more or less settles down...sometimes it keeps going for a while. My mechanic put an additive in the oil called stop the smoke or something, and i know that that causes the seals to expand...and it has helped. So. I need someone to give me an overall diagnosis and price range. My mechanic is reluctant to have me do the work, im guessing cause its expensive...but i would rather pay 1000 dollars then buy a new car.

- Do a compression test, that'll tell you exactly whats wrong. Or have a mechanic do one.

- Q: when riding my motorcycle valves start knocking i took to a mechanic and they did not resolve problem. i have baby ed my motorcycle. dint know what to do at this point and time.

- A lot of times you will not hear a valve problem, They tend to tighten up with age not loosen. On sign of a valve out of adjustment is if bike is hard to start when cold. knocking could be loose timing chain, timing chain tension-er needs attention.,Could also be worn drive chain. It will make a popping sound when its stretched out. Some front brake calipers will make a knocking sound, its the pads rattling around between calipers and rotors.

- Q: Also what prevents this from occuring? I have a lab due tomorrow for my biology class this is one of the questions. the answer is no where in my book, and we haven't discussed this in class. im also having a hard time finding the answer online. i would assume it would have something to do with the elasticity of the valves, and i know that when valves are weak sometimes blood can flow back into the artium when the ventricle contracts causing a heart murmur and other problems, but i haven't came across any information that talks about the valve being pushed backwards. if you can help me out that would be awesome! thanks =]

- the heart valves maintain the unidirectional flow of blood in the heart by opening and closing depending on the difference in pressure on each side. (wiki) So I would assume that the pressure of blood flow is what prevents the valve from pushing backwards. ALSO Atrioventricular valves These are small valves that prevent backflow from the ventricles into the atrium during systole. They are anchored to the wall of the ventricle by chordae tendineae, which prevent the valve from inverting. The chordae tendineae are attached to papillary muscles that cause tension to better hold the valve. Together, the papillary muscles and the chordae tendineae are known as the subvalvular apparatus. The function of the subvalvular apparatus is to keep the valves from prolapsing into the atria when they close. The subvalvular apparatus have no effect on the opening and closure of the valves, however. This is caused entirely by the pressure gradient across the valve.

- Q: I have a 04 Ford Ranger 4.0L . some people are saying that headers may affect the EGR valves and might put up the check engine light on. is this true or not.

- Check out what they call the DPFE sensor or the egr vacuum solenoid. This sensor controls the flow to the egr valve and your code will probably read: EGR insufficient flow. This sensor is very common and it is a dealer item only. 99% sure it isnt your egr itself. Part number : 4U7Z-9J460-AA dpfe sensor $76.40 F63Z-9J459-AA $29.98

- Q: Hi, I am a junior in high school and I play the trumpet. For the past week or so my 1st valve has been odd. It gets stuck badly when it hits all the way to the bottom, and I can't seem to get it to stop. Normally when valves are sticky I just use some valve oil and it helps a lot. But it doesn't seem to work this time. It is a Bach if that helps. I think there are other types of valves so I'll say that there is a spring inside from like the middle to top. If you could help me out that would be great! Thanks =)

- You don't mention if you've tried this or not, but it's possible that all the horn needs is a good cleaning. Wash all the parts in the sink in a bath of warm water and dish soap. Just be sure to give everything a good rinse when you're done. Then give everything a fresh coat of oil and it should work again.

- Q: Where is the PCV valve located on 2001 Nissan Altima

- Follow the line out of the bottom of the flux capacitor and you'll run right into it. The PCV valve on Altimas looks different than what has been common for years on most engines. The PCV valve is located at the drive belt side of the engine under the intake manifold and attached to the breather/separator. Access from above is very difficult; access the valve from underneath the vehicle. There is a short hose that connects to the breather/separator. Remove the breather/separator and the hose. Then you can unscrew the PCV valve from the breather/separator for easy inspection and cleaning of each piece. Also inspect both passages where the separator and hose connect. Here is a picture of the valve after it is removed. The breather/separator is a small aluminum housing that will fit in your hand.

- Q: I need an angle valve for my sink buts its a bit of an odd size. I have copper tubing at 1/2 i need a valve preferably compression that can feed to a water supply that is 1/2 Pipe thread.Included images of the supply hose valve to sink. To help show what i'm looking for.

- If you're looking for a valve that attaches to a 1/2 iron pipe coming out of the wall, and then will feed to 1/2 copper tubing, then you're looking for- an angle stop, 1/2 female iron pipe to 1/2 compression. Just about any good hardware store will have it in stock or be able to order it, just be sure that they know what you need. I've often found that using visual aids,like a piece of pipe in one hand, and a piece of tubing in the other, with an empty space, waiting for a valve, between them, can be an invaluable aid to communication. Don't even try to cut and adapt a braided hose. The stainless braid contains a (relatively thin) rubber hose. Without the braid to reinforce it, it will burst. If you need to adapt plumbing, there is always a way to get water from point A to point B. The challenge is finding the most elegant route.

- Q: how much is a head and valves job for a 92 chevy silverado 1500, v8 5.0L, extended cab, 204,xxx miles

- Mileage? by potential of no longer working you mean a ineffective hollow (no longer Firing) good? {Low Compression?} 80% is Boarder Line working no longer, 60% is thoroughly ineffective. you need to have a Leak Down try carried out to be sure if the problem is Valves or rings; Valves (Rebuild Head(s) Valves), rings (complete Engine Rebuild), wintry climate; Will start up perhaps however the tension will Drain the Battery after some starts.

- Q: I am looking at buying a 2001 Pontiac Bonneville and the guy said the car's check engine light says it had a problem with the EGR valve and so he bipassed it somehow. He said a EGR valve isn't needed. Is this valve very important or needed? What does it do? Thanks

- Yes it's vital for the car to run right and for smog or emissions testing too. I'd highly wonder about that car bec what else did he by pass. If you've not read the ECM's codes how do you know the engine light isn't on due to EGR valve and other faults with car. Best of luck and I hope this helps

Send your message to us

Swing Check Valve Wafer Type Double PN 4 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords